Porous carbon-based nano material, and preparation method and application thereof

A nanomaterial and porous carbon technology, applied in the field of nanomaterials, can solve the problems of inability to meet application requirements, small specific surface area, limited adsorption capacity, etc., and achieve the effect of improving use efficiency, large specific surface area, and large adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

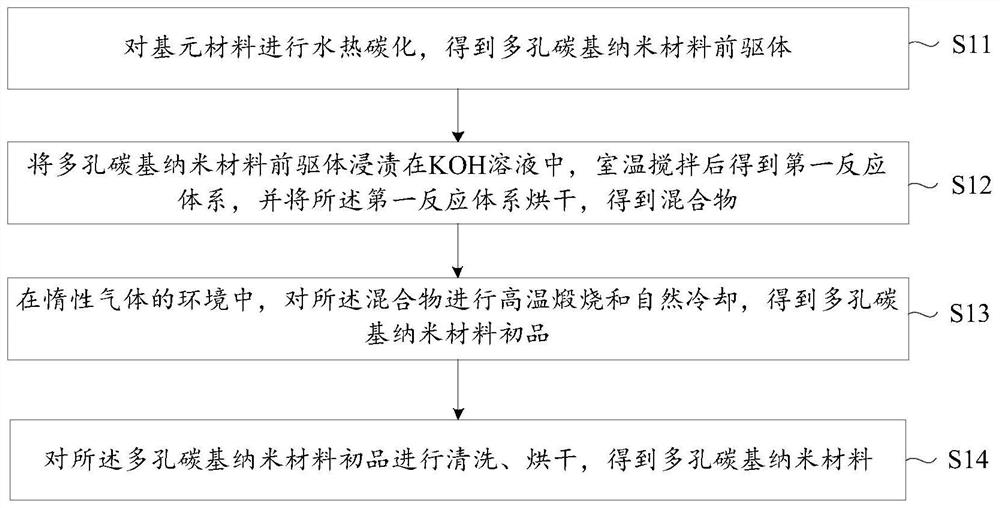

[0039] In the first aspect, embodiments of the present invention provide a method for preparing porous carbon-based nanomaterials, such as figure 1 As shown, the method includes:

[0040] Step 1 (S11), hydrothermally carbonizing the elementary material to obtain a porous carbon-based nanomaterial precursor.

[0041] During specific implementation, add the basic element material into the dispersant, stir until the basic element material is fully dissolved, and obtain the basic element material solution; place the basic element material solution in a hydrothermal reaction kettle, and place the reaction kettle in an oven , react at 180-240° C. for 19-25 hours, cool to room temperature after the reaction is completed; centrifuge and filter the reacted product to obtain a porous carbon-based nanomaterial precursor. Wherein, the dispersant is deionized water or ultrapure water.

[0042] In this embodiment, optionally, the base material includes: waste bean dregs powder, coconut sh...

Embodiment 1

[0057] Take 50g of waste bean dreg powder and add it into 75mL of pure water, stir for more than 2h, make it fully and evenly dispersed in deionized water, and then move it into a 100mL hydrothermal reaction kettle. Then put the reaction kettle with the okara powder solution into an oven, react at 220° C. for 24 hours, then cool to room temperature, and filter the obtained product, and the obtained solid product is a porous carbon-based nanomaterial precursor.

[0058] In the next step, the resulting precursor was chemically activated with KOH. First, the precursor was immersed in a 1 Mol / L KOH solution (KOH:precursor = 3:1) and stirred continuously overnight at room temperature. The mixture was then dried in an oven at 165°C. Next, the dried and ground mixture was heat-treated in a stainless steel reactor placed in a vertical tube furnace. Set the temperature at 800° C., and heat for four hours under the protection of nitrogen, and then cool under the protection of nitrogen...

Embodiment 2

[0079] Take 50g of waste bean dregs powder and add it into 75mL of pure water, stir for 3h, make it fully and evenly dispersed in ultrapure water, and then move it into a 100mL hydrothermal reaction kettle. Then put the reactor containing the bean dregs powder solution into an oven, react at 200° C. for 20 h, then cool to room temperature, and filter the obtained product, and the obtained solid product is a porous carbon-based nanomaterial precursor.

[0080] In the next step, the resulting precursor was chemically activated with KOH. First, the precursor was immersed in a 1 Mol / L KOH solution (KOH:precursor = 3:1) and stirred continuously overnight at room temperature. Then the mixture was dried in an oven at 150°C. Next, the dried and ground mixture was heat-treated in a stainless steel reactor placed in a vertical tube furnace. Set the temperature to 700°C, and under the condition of nitrogen protection, when the temperature rises to 700°C, heat for another 3 hours, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com