Garbage pyrolysis gasification treatment device

A technology of pyrolysis gasification and treatment device, applied in grain treatment, packaging, transportation and packaging, etc., can solve the problems of waste gas affecting natural ecology and environmental protection, damage to recyclable items, waste of limited material resources, etc., to achieve convenient Sorting processing, convenient secondary processing, and the effect of enhancing practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

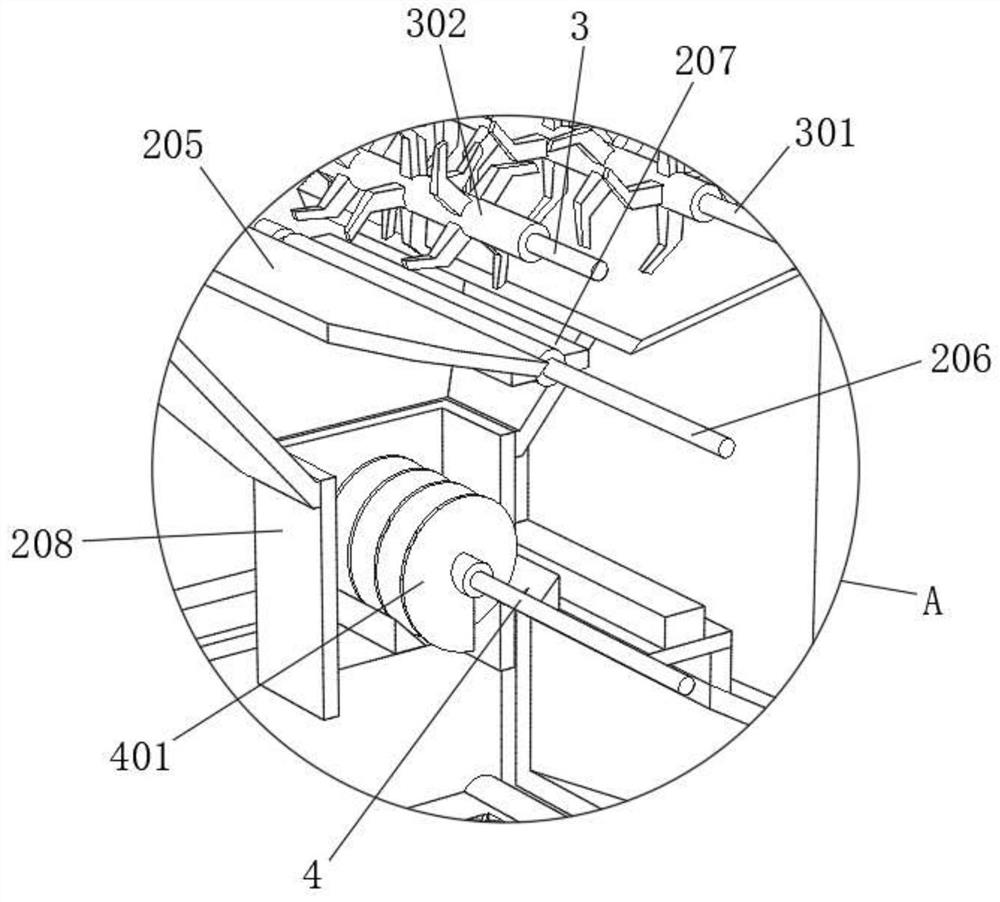

[0035] refer to Figure 1-Figure 6 , a garbage pyrolysis gasification treatment device, comprising a base plate 1, the upper surface of the base plate 1 is fixed with a frame 2 by bolts, the upper surface of the frame 2 is fixed with a treatment box 201 by bolts, and the upper surface of the treatment box 201 is provided with a feed inlet , the upper surface of the feed inlet is fixed with a hollow plate 202 by bolts, the upper surface of the hollow plate 202 is fixed with a support frame 203 by bolts, the inner wall of the support frame 203 is fixed with the same storage bucket 204 by bolts, and the bottom of the storage bucket 204 is provided with a discharge In the discharge port, a discharge cylinder 208 is fixed by bolts, and the inner walls of both sides of the storage bucket 204 are rotatably connected with a driving shaft 3, a driven shaft 301 and a rotating rod 206, and one side of the rotating rod 206 is provided with a first belt 305 and a second belt. Two belts 402...

Embodiment 2

[0039] refer to Figure 7 , the upper surface of the processing barrel 7 is fixed with a supporting arc plate 11 by bolts, and the upper surface of the supporting arc plate 11 is fixed with a hot air blower 1101 by bolts, and the garbage in the processing barrel 7 is dried and heated by the hot air blower 1101 on the supporting arc plate 11. Chemical treatment, avoiding the adhesion of non-metallic garbage, facilitating the transfer of garbage in the treatment barrel 7 by the transfer mechanism, and improving the efficiency of the device's operation and processing. The upper surface of the bottom plate 1 is provided with a storage box 12, and the outer wall of the storage box 12 is provided with a seal The bottom of the sealing port is rotatably connected with a sealing plate 1201, and the multi-side inner wall of the storage box 12 is fixed with the same partition 1202 by bolts, and the cooperation of the storage box 12 and the partition 1202 can concentrate the metal scraps o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com