Vacuum cleaner

A technology for vacuum cleaners and suction openings, which is applied in the direction of vacuum cleaners, suction filters, robot cleaning machines, etc., and can solve the problems of users being exposed to dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

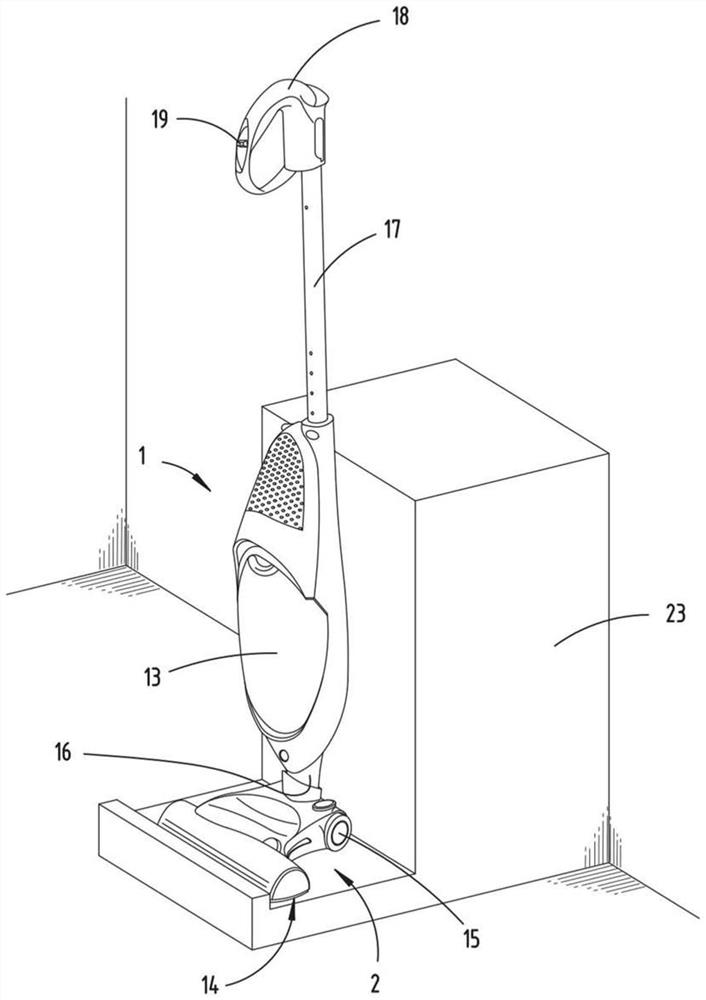

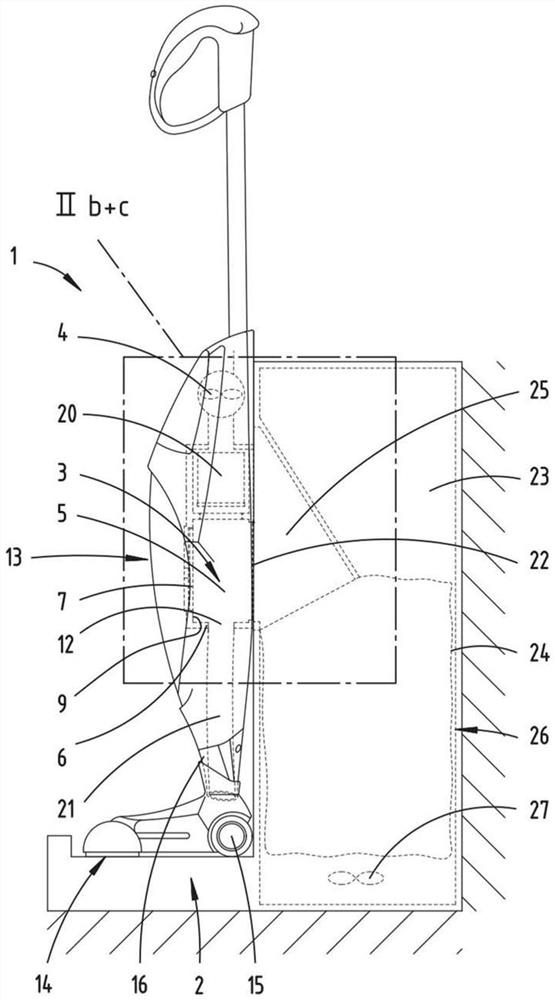

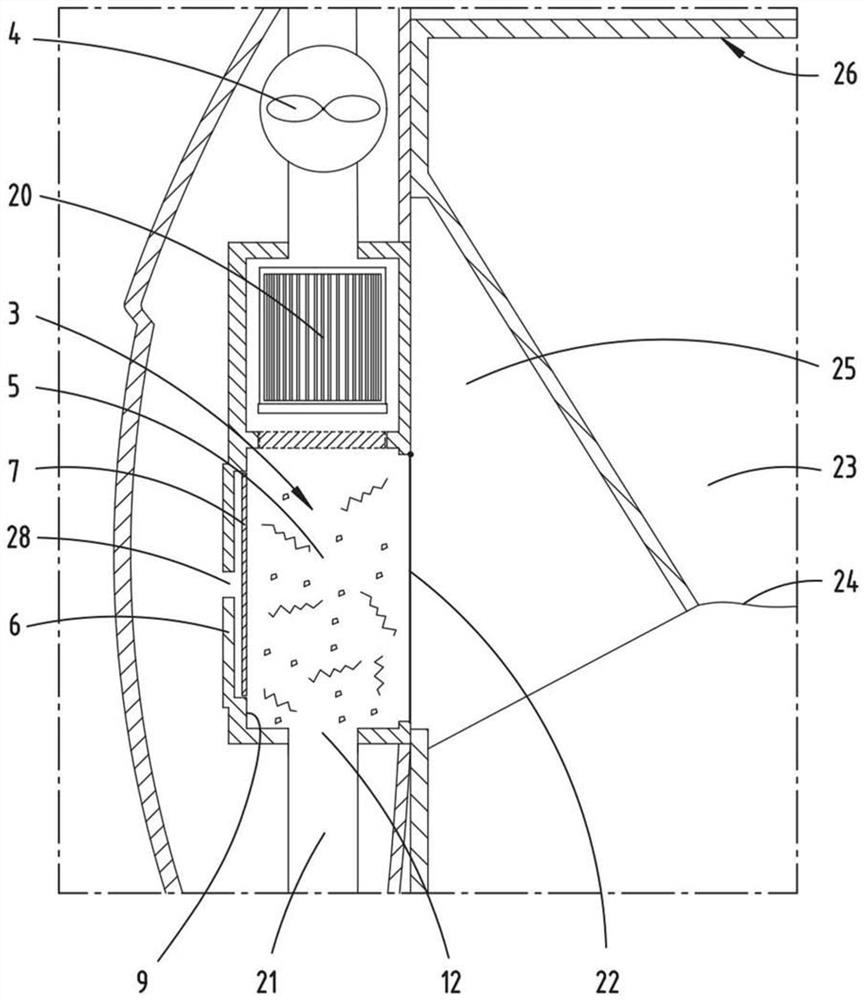

[0029] figure 1 A vacuum cleaner 1 disposed on the base station 23 is shown. The vacuum cleaner 1 is exemplarily designed as a hand-held vacuum cleaner 1, which has a base apparatus 13 and a nozzle 2 as a detachable attachment. The suction mouth 2 has a suction port 14, and the suction can be sucked into the vacuum cleaner 1 to be cleaned by the suction port 14. In order to facilitate the movement of the vacuum cleaner 1 to move on the surface to be cleaned, the suction nozzle 2 has a wheel 15. The base apparatus 13 and the nozzle 2 are detachably connected to each other by the connection region 16 such that the suction nozzle 2 may be alternatively replaced with other nozzle 2. On the base device 13 having a handle 17 with a handle 18, the user can guide the vacuum cleaner 1 on the surface to be cleaned by the handle 17. This is usually carried out in successive back-to-back motion. The handle 17 is preferably a telescopically, allowing the user to adjust the height of the handl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com