Slurry for improving color and luster of conditioned meat product and conditioned meat product using same

A technology of meat products and slurry, which is applied in the field of slurry for improving the color of conditioned meat products and the field of conditioned meat products, can solve the problems that cannot be achieved, and there are few researches on the coloring effect of pigments, and achieve the effect of enhancing the coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

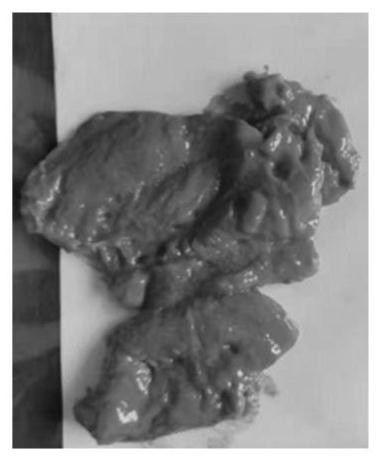

Image

Examples

Embodiment 1

[0048] This embodiment relates to the preparation of a conditioning meat product, comprising the following steps:

[0049] 1) Weigh 40 parts of water, and control the water temperature between 0-10°C;

[0050] 2) Add 1 part of composite phosphate water-retaining agent, 10 parts of corn starch, 3.5 parts of compound coloring enhancer (including 0.25 parts of pectin, 0.25 parts of carrageenan, 2.0 parts of sodium caseinate, 0.75 parts of soybean protein isolate) to the above water , 0.25 parts of enzymatically hydrolyzed soybean lecithin), 7 parts of marinade into the water in step 1), mix evenly, and control the temperature between 0-10°C during the mixing process;

[0051] 3) Cut and shape 100 parts of chicken breast raw materials, put them into the compound material liquid in step 2), and knead for 45 minutes, and the process control temperature remains unchanged;

[0052] 4) Add 1 portion of capsicum red and edible oil in step 3), continue to roll and knead for 25 minutes, ...

Embodiment 2

[0055] This embodiment relates to the preparation of a conditioning meat product, comprising the following steps:

[0056] 1) Weigh 40 parts of water, and control the water temperature between 0-10°C;

[0057] 2) Weigh 1 part of composite phosphate water-retaining agent, 10 parts of cornstarch, 4.5 parts of compound coloring enhancer (including 0.25 parts of pectin, 0.25 parts of carrageenan, 2.0 parts of sodium caseinate, 1.0 parts of glyceryl distearate , soybean lecithin 1.0), 7 parts of marinade, add to the water in step 1), mix evenly, and control the temperature between 0-10°C during the mixing process;

[0058] 3) Cut and shape 100 parts of chicken breast raw materials, put them into the compound material liquid in step 2), and knead for 45 minutes, and the process control temperature remains unchanged;

[0059] 4) Add 1 portion of capsicum red and cooking oil in step 3), continue to roll and knead for 25 minutes, and keep the process temperature unchanged;

[0060] 5...

Embodiment 3

[0062] This embodiment relates to the preparation of a conditioning meat product, comprising the following steps:

[0063] 1) Weigh 40 parts of water, and control the water temperature between 0-10°C;

[0064]2) Weigh 1 part of composite phosphate water-retaining agent, 10 parts of corn starch, 3.0 parts of compound coloring enhancer (including 0.2 parts of pectin, 1.5 parts of carrageenan, 0.5 parts of locust bean gum, and 0.5 parts of guar gum) according to the above ratio , 0.3 parts of xanthan gum), 7 parts of marinade into the water in step 1), mix evenly, and control the temperature between 0-10°C during the mixing process;

[0065] 3) Cut and shape 100 parts of chicken breast raw materials, put them into the compound material liquid in step 2), and knead for 45 minutes, and the process control temperature remains unchanged;

[0066] 4) In step 3), add 1 portion of capsicum red and an appropriate amount of cooking oil, continue to roll for 25 minutes, and keep the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com