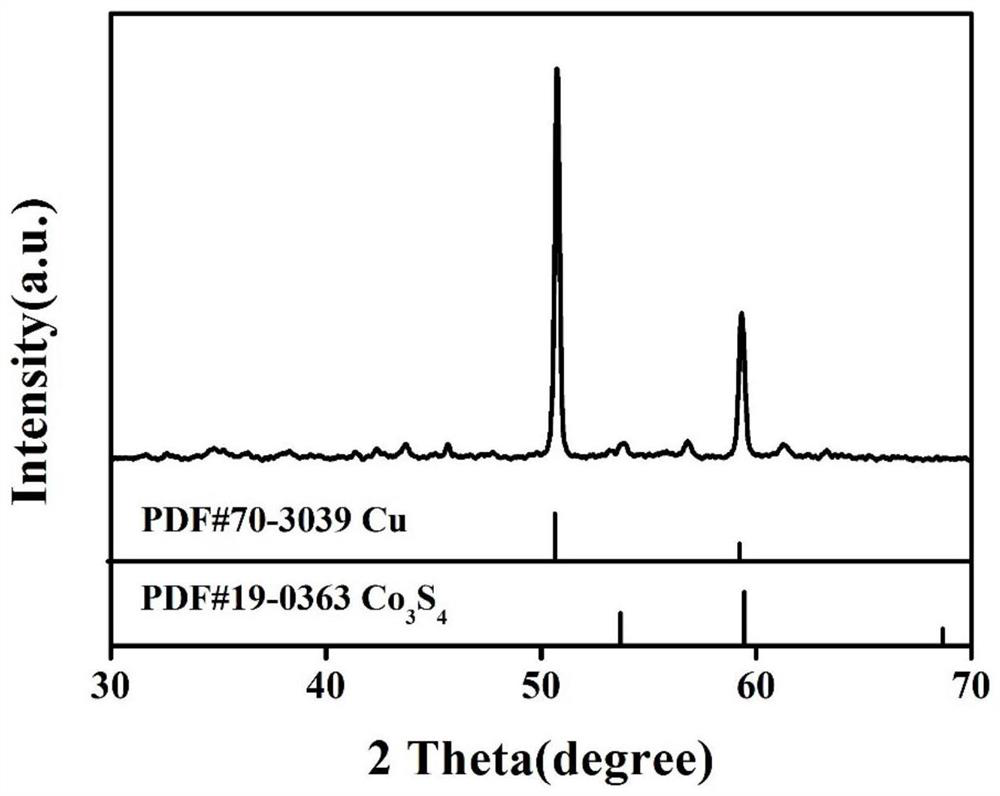

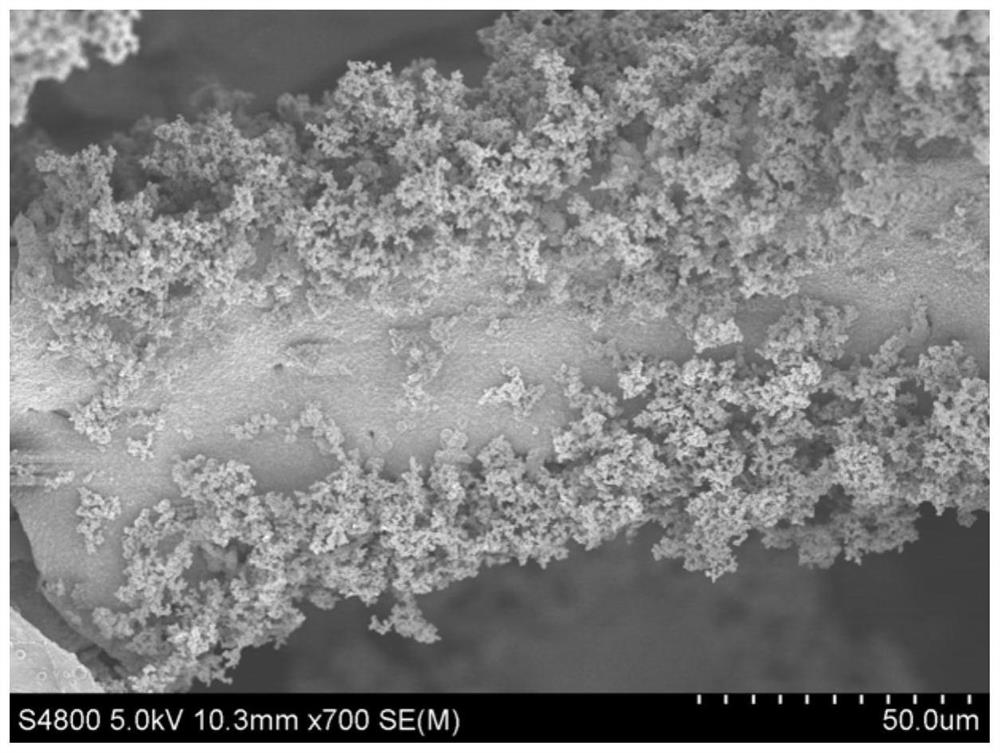

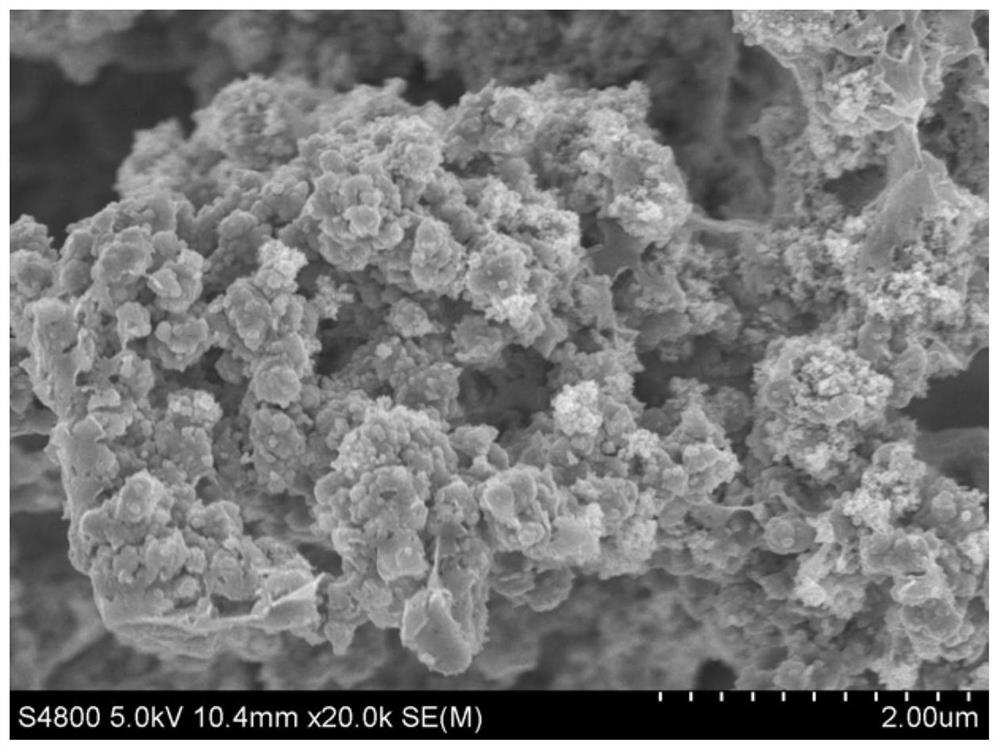

Foamy copper potassium ion battery material and preparation method thereof

A battery material and foamed copper technology, which is applied in the field of electrochemistry, can solve the problems of hindering the contact and infiltration of active materials and electrolytes, affecting the effective occurrence of cobalt sulfide conversion reaction, and the inability of the electrochemical reaction to react completely. The experimental conditions are easy to achieve, Excellent electrochemical performance and the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Dissolve cobalt sulfate in a mixed solution of 40 mL of absolute ethanol and 10 mL of oleic acid, and magnetically stir at a speed of 600 r / min to form a clear solution A with a cobalt sulfate concentration of 0.02 mol / L;

[0029] 2) Add 0.15 g of thiourea into solution A, and stir at the same speed to obtain uniformly mixed solution B;

[0030] 3) Cut the self-supporting substrate foam copper with a thickness of 1 mm into a foam copper sheet with a size of 3 × 3 cm, and then completely soak the foam copper sheet in acetone and 2mol / L hydrochloric acid solution for 30 minutes respectively to obtain pretreatment The copper foam sheet; the role of pretreatment is to remove the oxides and impurities on the copper foam, to avoid the impact of impurities on the copper foam on the preparation process.

[0031] 4) Transfer the solution B into the hydrothermal reaction kettle, put the pretreated foamed copper sheet into it at the same time, and put it into the homogeneous re...

Embodiment 2

[0037] 1) Dissolve cobalt sulfate in a mixed solution of 43 mL of absolute ethanol and 9 mL of oleic acid, and magnetically stir at a speed of 650 r / min to form a clear solution A with a cobalt sulfate concentration of 0.04 mol / L;

[0038] 2) Add 0.2 g of thiourea to solution A, and stir at the same speed to obtain a uniformly mixed solution B;

[0039] 3) Cut the self-supporting substrate foam copper with a thickness of 1mm into a foam copper sheet with a size of 3 × 3cm, and then completely soak the foam copper sheet in acetone and 2.2mol / L hydrochloric acid solution for 40min respectively, and obtain the preliminary Processed copper foam;

[0040] 4) Transfer the solution B into the hydrothermal reaction kettle, put the pretreated foamed copper sheet at the same time, seal it and carry out the solvothermal reaction in the homogeneous reactor at a speed of 7r / min from room temperature to 130°C After 8.5 hours of reaction, the product was alternately washed with deionized wa...

Embodiment 3

[0042] 1) Dissolve cobalt sulfate in a mixed solution of 40 mL of absolute ethanol and 8 mL of oleic acid, and magnetically stir at a speed of 700 r / min to form a clear solution A with a cobalt sulfate concentration of 0.05 mol / L;

[0043] 2) Add 0.25 g of thiourea into solution A, and stir at the same speed to obtain uniformly mixed solution B;

[0044] 3) Cut the self-supporting substrate foam copper with a thickness of 1mm into a foam copper sheet with a size of 3 × 3cm, and then completely soak the foam copper sheet in acetone and 2.5mol / L hydrochloric acid solution for 50min respectively, and obtain the preformed Processed copper foam;

[0045] 4) Transfer the solution B into the hydrothermal reaction kettle, put the pretreated foam copper sheet at the same time, seal it, and carry out the solvothermal reaction in the homogeneous reactor at a speed of 8r / min from room temperature to 140°C After 9 hours of reaction, the product was alternately washed three times with deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com