A multi-stage fireproof material

A fireproof material, multi-stage technology, applied in fire prevention, fire rescue, chemical instruments and methods, etc., can solve the problems of fireproof material failure, mildew, difficult to prevent high temperature diffusion, etc., and achieve the effect of improving fireproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

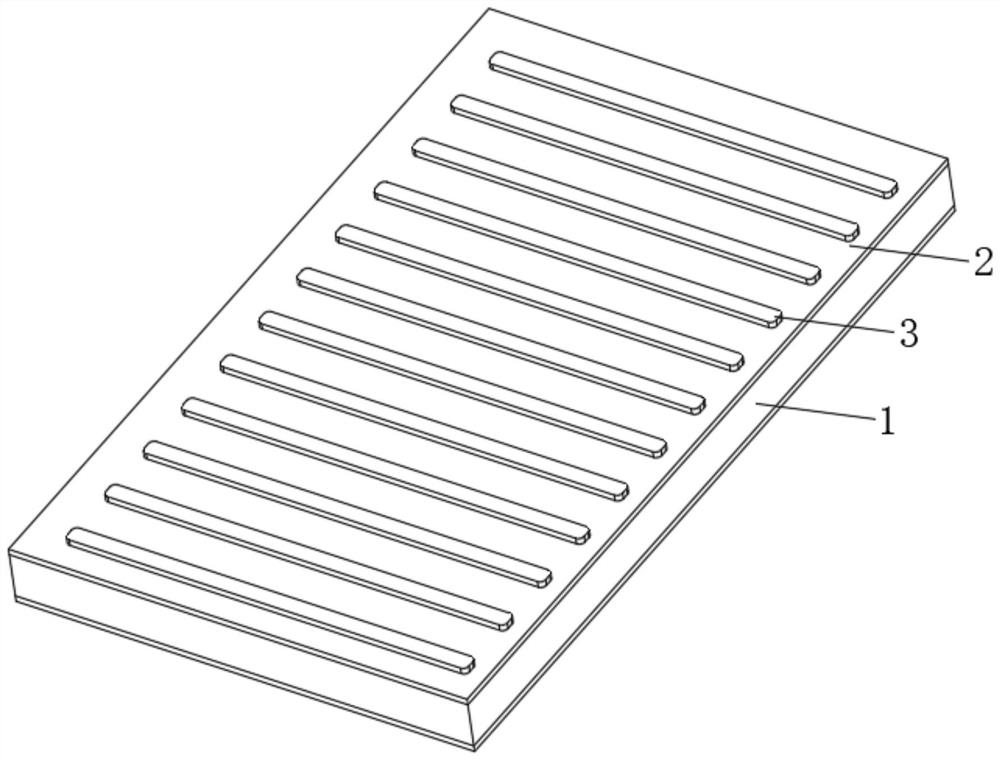

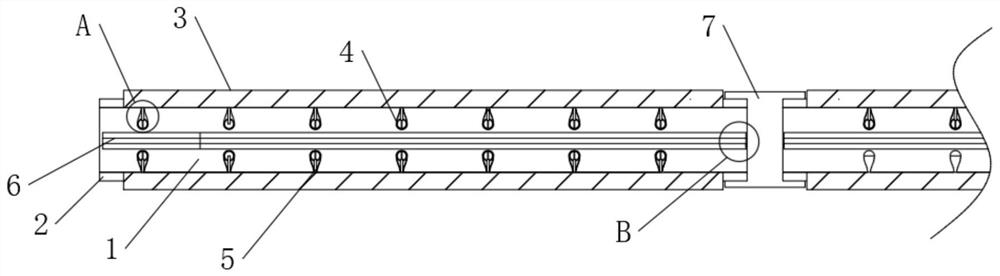

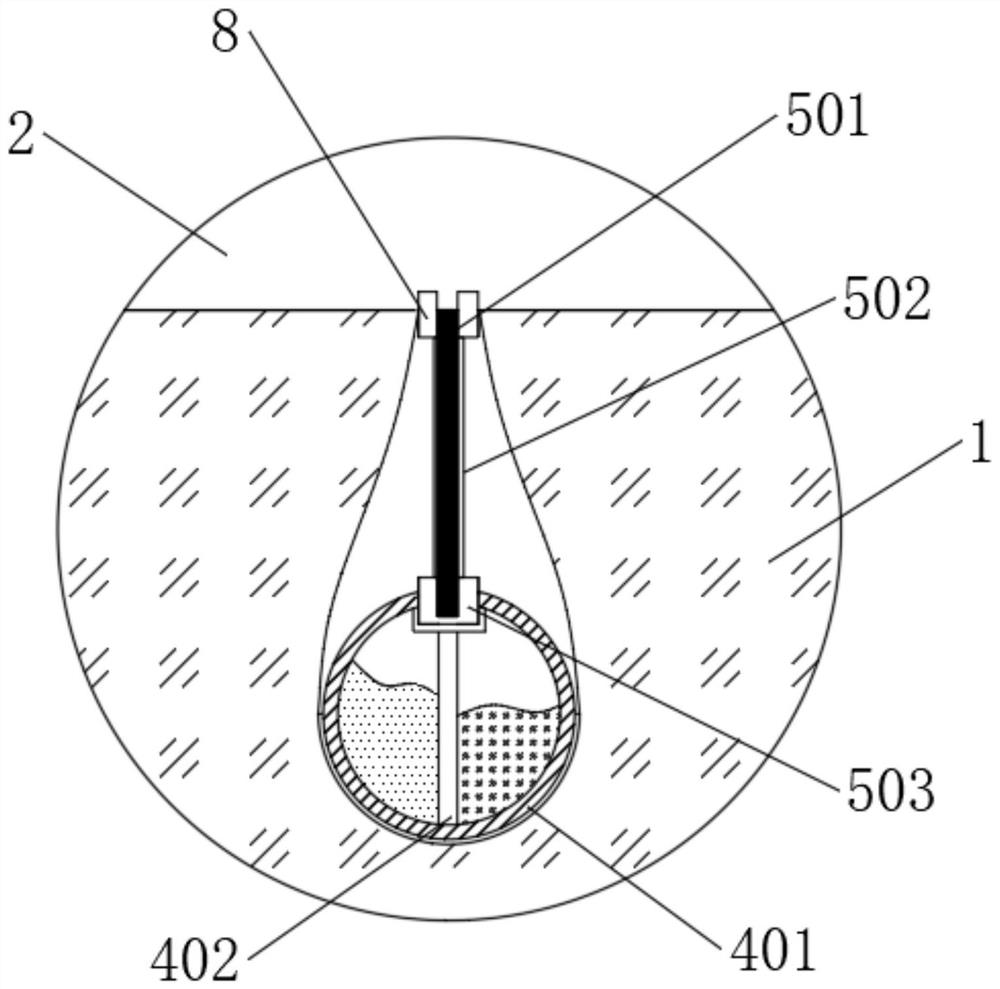

[0043] see Figure 1-3A multi-segment fireproof material includes a plurality of fireproof base belts 1, the fireproof base belt 1 is made of a heat insulating material, the fireproof base belt 1 has a porous structure, the thickness of the fireproof base belt 1 is 5-8cm, and the fireproof base belt 1 is filled with fireproof foam. , the fireproof foam is permeated with flame retardant liquid, so that the fireproof base tape itself has a certain fireproof performance. A partition 7 is connected between two adjacent fireproof base tapes 1, and a plurality of evenly distributed extrusion grooves are opened on the fireproof base tape 1. 101, the extrusion groove 101 is in the shape of a water drop after being squeezed by the exposing balloon 4, the distance between two adjacent extruding grooves 101 is 20-30CM, and the extruding balloon 4 is in a squeezed state, which is generated in the exposing balloon 4. After the gas is discharged, it is convenient that the gas can be quickly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com