Combined roof with plug-in waterproof structure

A composite roofing and roofing technology, which is applied to roofing, roofing with flat/curved panels, and roof coverings, etc., can solve problems such as water leakage, boards without fireproof layers, and fires, and achieve water penetration prevention, convenient and quick installation, and The effect of prolonging the service life

Inactive Publication Date: 2016-01-20

ZHONGQI JIAOJIAN GRP

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the steel structure factory building is favored by various owners for its light weight, beautiful appearance, short construction period, and large span, which also makes the steel structure building develop rapidly. Sunshine and other problems, the roof panels are glued and rusted, resulting in water seepage, water leakage, poor thermal insulation performance, and many factory building panels have no fireproof structures, causing fires and serious losses

[0003] The above-mentioned defects, some of which are caused by accidents due to the lack of a fireproof layer of the board, and some of which are caused by the fact that the roof board must be fixed on the roof purlin during installation and bolts are used to penetrate the entire board, resulting in water leakage and poor thermal insulation performance.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0020] The installation technological process of the present invention is as follows:

[0021] Pre-construction preparation→check the steel beams→grid and spring line→install the composite roof body→drill holes in the bolt grooves and use fixing bolts to fix the composite roof body and roof purlins→glue the concave-convex joints→insert the composite roof body → Handle the stitching seam → Acceptance.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

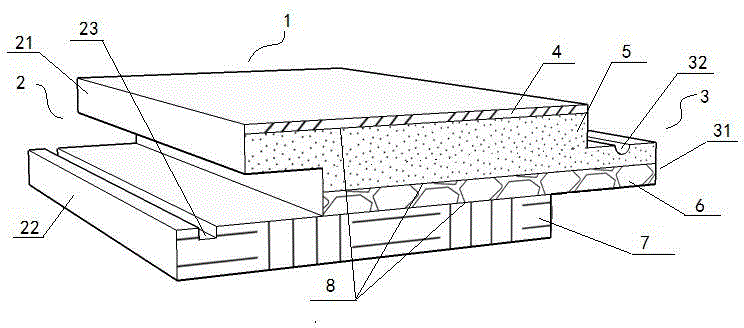

A combined roof with a plug-in waterproof structure comprises a combined roof body integrally formed and composed of a plurality of layers of a composite material. The combined roof body is disposed transversely on roof purlins. The left and right ends of the combined roof body transversely disposed are provided with a concave groove and a convex edge, respectively, a lower protrusion of the concave groove of the combined roof body transversely disposed is twice as long as an upper protrusion, the side, longer than the upper protrusion, of the lower protrusion of the concave groove is longitudinally provided with a bolt slot, the upper side of a middle protrusion of the convex edge of the combined roof body transversely disposed is longitudinally provided with a guide groove, and a high-molecular polymer filling space between the concave groove and the convex edge is used for splicing multiple composite board bodies. The plug-in waterproof structure using mutual fitting of concave and convex structures is quick, easy and convenient to mount, bolts are hidden, the guide groove and the bolt slot are provided, and thus the whole roof is attractive, firm to mount, waterproof and fireproof and excellent in thermal insulation.

Description

technical field [0001] The invention relates to a composite roof, in particular to a composite roof with a plug-in waterproof structure. Background technique [0002] At present, the steel structure factory building is favored by various owners for its light weight, beautiful appearance, short construction period, and large span, which also makes the steel structure building develop rapidly. Problems such as sun exposure, roof panels are glued and rusted, resulting in water seepage, water leakage, poor thermal insulation performance, and many factory building panels have no fireproof structure, causing fires and serious losses. [0003] Some of the above-mentioned defects are caused by accidents due to the lack of a fireproof layer on the board, and some are due to the fact that the roof board must be fixed on the roof purlin during installation and bolts are used to penetrate the entire board, resulting in water leakage and poor thermal insulation performance. [0004] The...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04D3/35E04D3/362E04D3/40E04D13/04

Inventor 律殿津

Owner ZHONGQI JIAOJIAN GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com