High-span section strong karst filler treatment construction method and curtain anti-seepage method

A construction method and filling technology, which are applied in basic structural engineering, construction, sheet pile walls, etc., can solve the problems of difficult processing of strong karst fillings, threatening the safety of curtain seepage construction, etc., to solve the problem of limited working space, The effect of reducing the difficulty of processing and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A construction method for treating strong karst fillings in high-span sections, comprising the following steps:

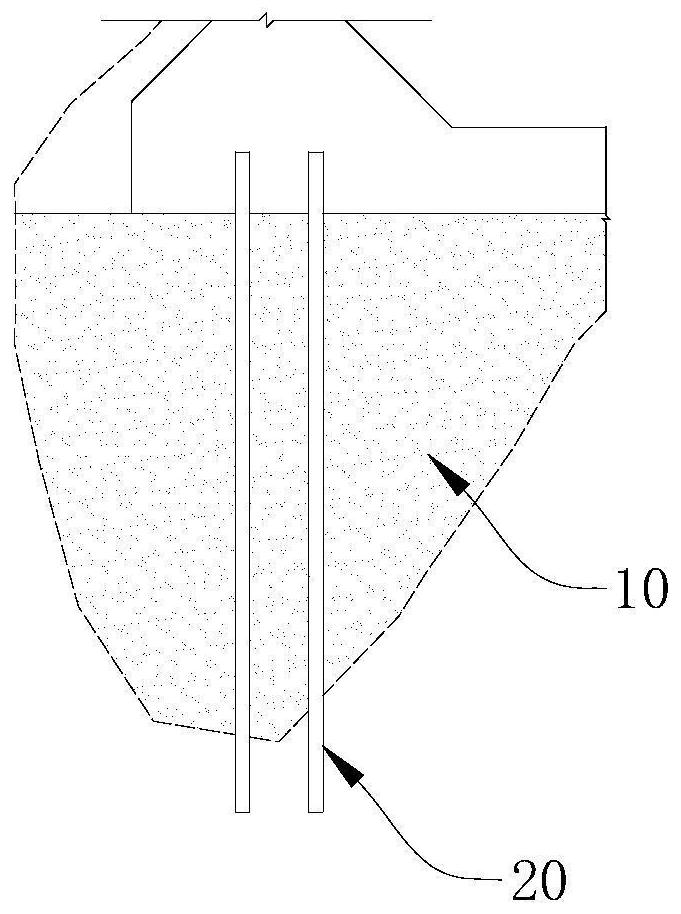

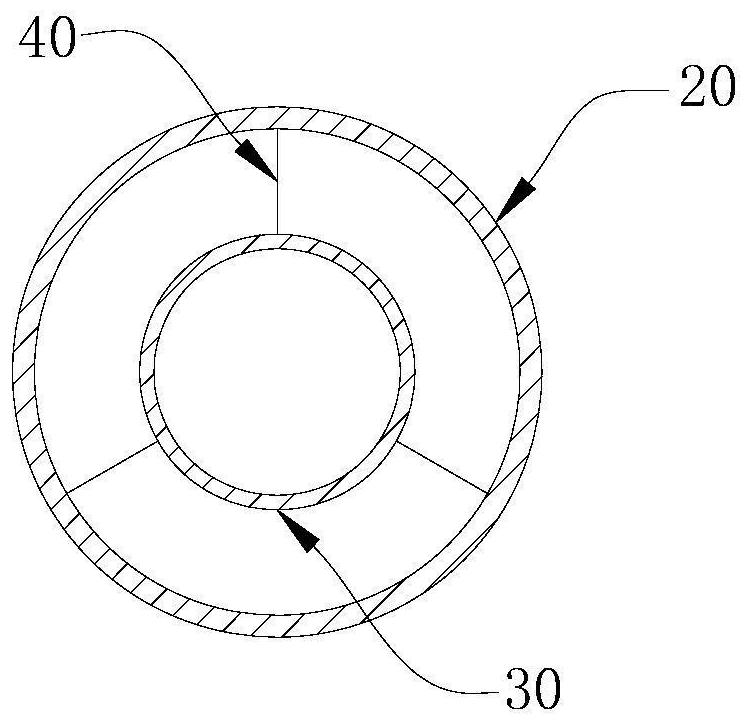

[0043] S1: For the strong karst filling in the karst cave, drill high-pressure jet nozzles in the foundation treatment range of the concrete corridor. High-pressure rotary spraying treatment to form rotary spraying body 10, and curing for 28 days.

[0044] S2: Drill inspection holes in sections from top to bottom on the axis of the curtain and take core samples. The diameter of the inspection holes is ≥ 60mm, and the depth of the inspection holes is less than 2m below the adjacent high-pressure jetting holes. The hole is subjected to hydrostatic head pressure test, and the obtained core samples are subjected to 28-day and 90-day saturated compressive strength tests respectively; -7 cm / s), proceed to the next step; if the test and test fail, carry out high-pressure rotary spraying reinforcement until the test and test pass.

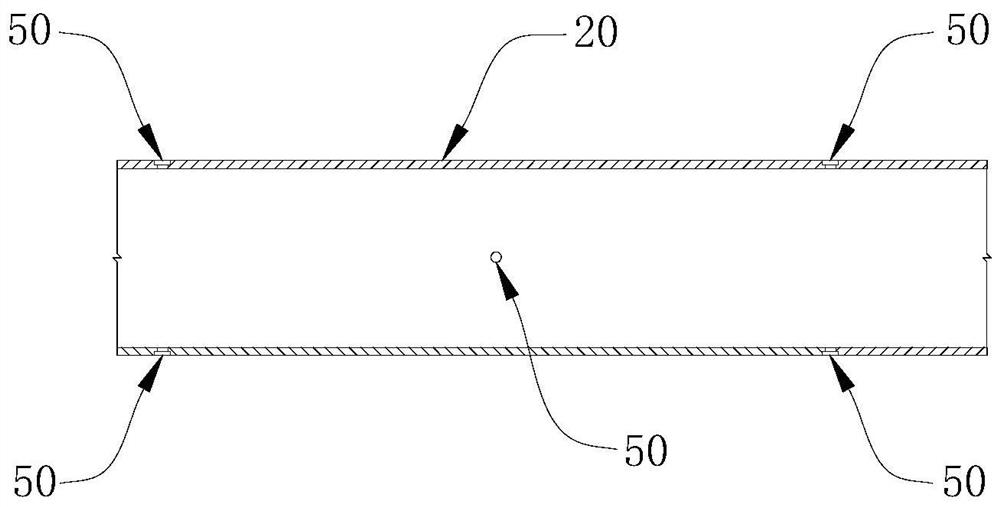

[0045] S3: Drill multiple insta...

Embodiment 2

[0052] A curtain anti-seepage method based on the above-mentioned construction method for treating strong karst fillings in high-span sections, adopts a conventional curtain grouting method for curtain anti-seepage, and constructs the curtain grouting hole section at the lower part of the cave through a casing. The present invention adopts the conventional and mature curtain grouting method to carry out the curtain grouting method on the karst cave containing strong karst filling, without changing the original curtain grouting scheme, reducing the difficulty of anti-seepage construction, and using the pre-buried casing to grout the curtain at the lower part of the karst cave Hole construction can speed up the construction progress, improve the grouting efficiency, and the grouting quality after grouting is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com