High-filling modified polyacrylate optical adhesive composition, OCA pressure-sensitive adhesive tape and preparation method of OCA pressure-sensitive adhesive tape

A technology of polyacrylate and pressure-sensitive tape, which is applied in non-polymer organic compound adhesives, pressure-sensitive films/sheets, non-polymer adhesive additives, etc., and can solve problems that are difficult to achieve 100% success and require waste discharge Tape, complex process and other problems, to achieve the effect of improving secondary utilization, improving filling, and enhancing modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0054] Embodiments 1-6: Synthesis of curable (meth)acrylate copolymers

[0055] Taking Example 1 as an example, its synthesis method is: under a nitrogen atmosphere with a flow rate of 0.2L / min, add 75 parts of dodecyl acrylate, 15 parts of acrylic acid to a flask equipped with a reflux device, a thermometer and a stirring device Isobornyl ester, 10 parts of hydroxyethyl acrylate, and 100 parts of ethyl acetate were stirred to dissolve the monomers, and then the temperature was raised to 65°C, and 0.1 parts of thermal initiator azobisisobutyronitrile was put into the polymerization reaction; the reaction was 6h After cooling and heating, the (meth)acrylate copolymer adhesive was obtained, which was denoted as A1.

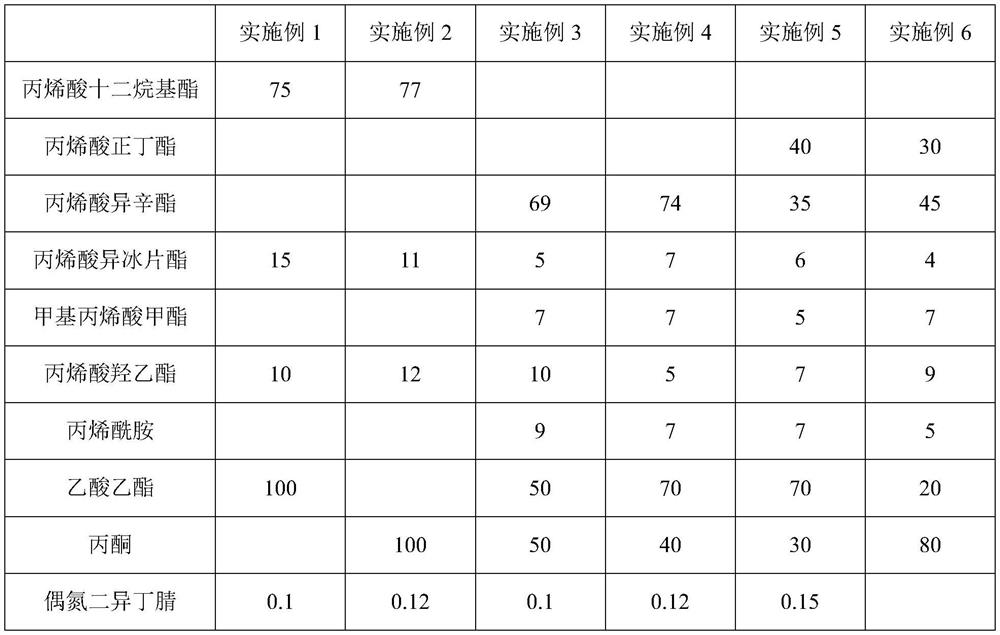

[0056] The synthesis method of Examples 2-6 is similar to that of Example 1, and the obtained products are marked as A2-A6. The specific formula is shown in Table 1.

[0057] The component formula table of table 1 embodiment 1~6

[0058]

[0059]

Embodiment 7~12

[0060] Examples 7-12: Grafting reaction of curable (meth)acrylate copolymer

[0061] Taking Example 7 as an example, its synthesis method is: add 100 parts of acrylate copolymer A1, 0.2 part of 2-(meth)acryl ethyl isocyanate to a reaction flask equipped with a reflux device, a thermometer and a stirring device Ester and 0.1 part of antioxidant IRGANOX 1726, stirred evenly and heated up for 5 hours, then cooled down to obtain grafted (meth)acrylate copolymer B1.

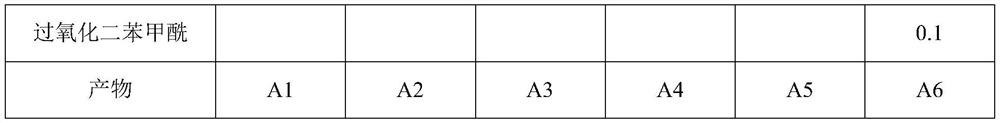

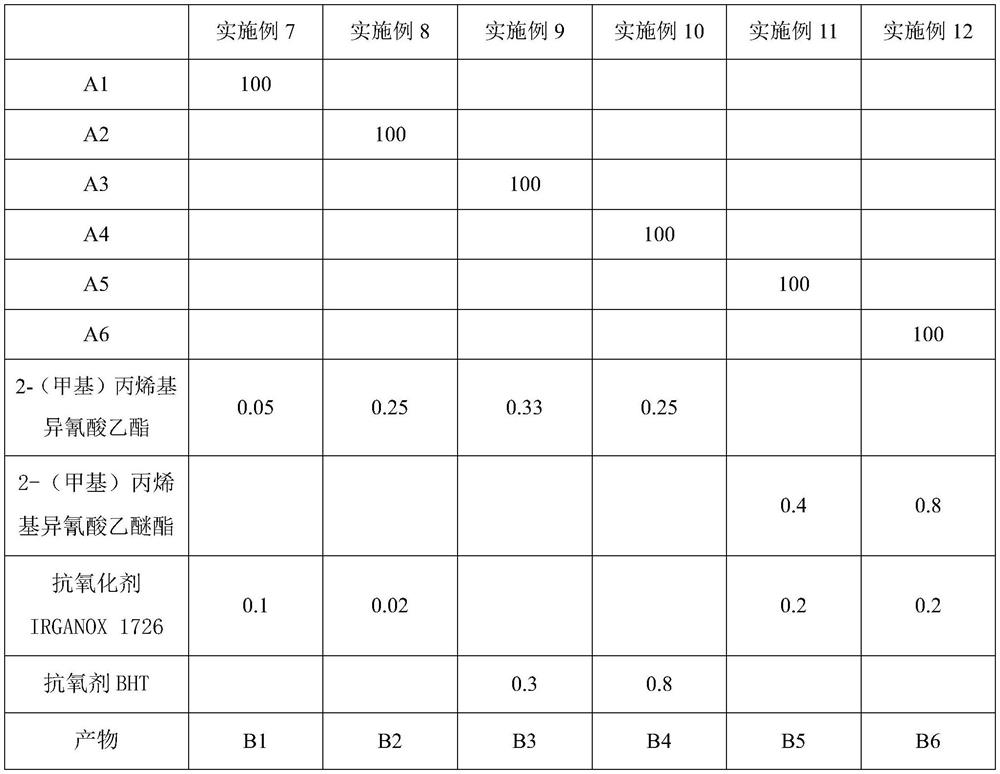

[0062] The synthesis method of Examples 8-12 is similar to that of Example 7, and the obtained products are marked as B2-B6. The specific formula is shown in Table 2.

[0063] The component formula table of table 2 embodiment 7~12

[0064]

Embodiment 13~18、 comparative example 1~3

[0065] Examples 13-18, Comparative Examples 1-3: Preparation of OCA pressure-sensitive adhesive tape

[0066] Taking Example 13 as an example, the preparation method of OCA adhesive tape is as follows: 100 parts of grafted (meth)acrylate copolymer adhesive B1, 0.1 part of photoinitiator IRGACURE 184, 3 parts of multifunctional monomer SR259 are mixed and stirred evenly After standing still for defoaming, an acrylic pressure-sensitive adhesive is formed. Coat the acrylic pressure-sensitive adhesive on the heavy release film, bake it at 120°C for 5 minutes, and then attach it to the light release film to form light release film, acrylic The three-layer structure of pressure-sensitive adhesive and heavy-release film is to obtain substrate-free OCA pressure-sensitive adhesive tape C1.

[0067] The preparation method of the OCA tapes of Examples 14-18 and Comparative Examples 1-3 is similar to that of Example 13, and the obtained samples are marked as C2-C9. The specific formula ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| gel fraction | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com