Plastic explosive cutting mechanism

A technology of explosives and plasticity, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of high labor intensity, large weight error of plastic explosive blocks, and low production efficiency, so as to reduce labor intensity, eliminate potential safety hazards, and improve The effect of production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

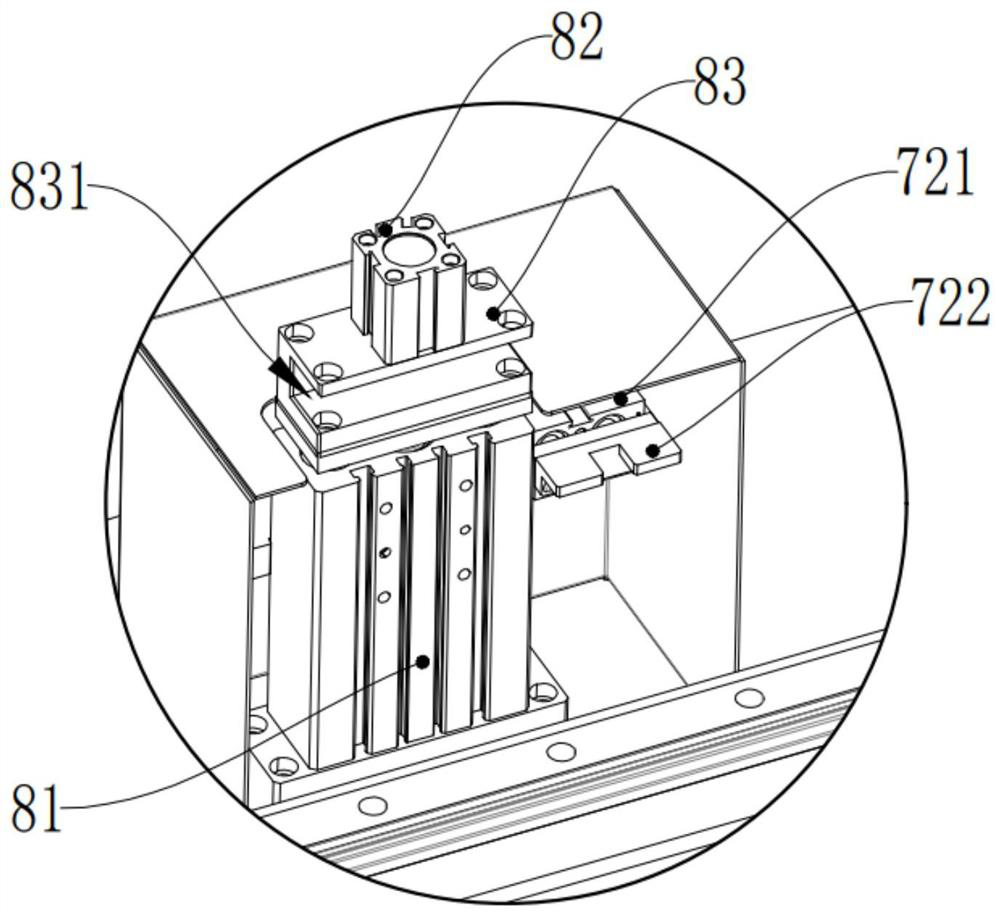

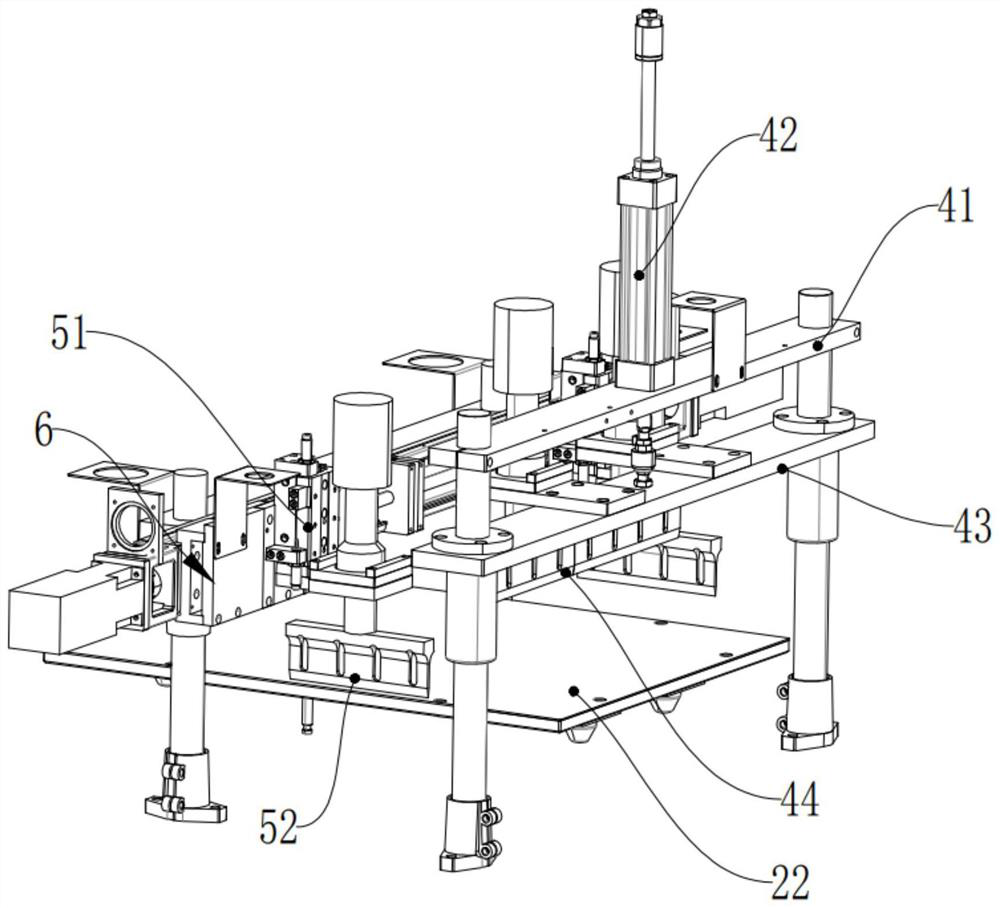

[0035] For a plastic explosive cutting mechanism of this embodiment, refer to the attached figure 1 , including a workbench 1 and a linear movement assembly 2, a drug-carrying tray 3, a first punching assembly 4, a second punching assembly 5, and a translation assembly 6 arranged on the worktable 1;

[0036] The first punching assembly 4 and the translation assembly 6 are arranged on the top of the linear movement assembly 2, the second punching assembly 5 is arranged at the movable end of the translation assembly 6, and the drug-loaded tray 3 is detachably arranged at the movable end of the linear movement assembly 2 , the drug-loaded tray 3 is used to carry plastic explosives, and a silica gel layer is laid on the drug-loaded tray 3;

[0037] The first punching assembly 4 is used for transverse p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com