Automatic guided vehicle for logistics carrying

A technology that automatically guides trolleys and logistics handling. It is used in transportation and packaging, construction, mechanical conveyors, etc. It can solve the problems of unstable cargo handling and small contact area, so as to improve service life, increase contact area, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

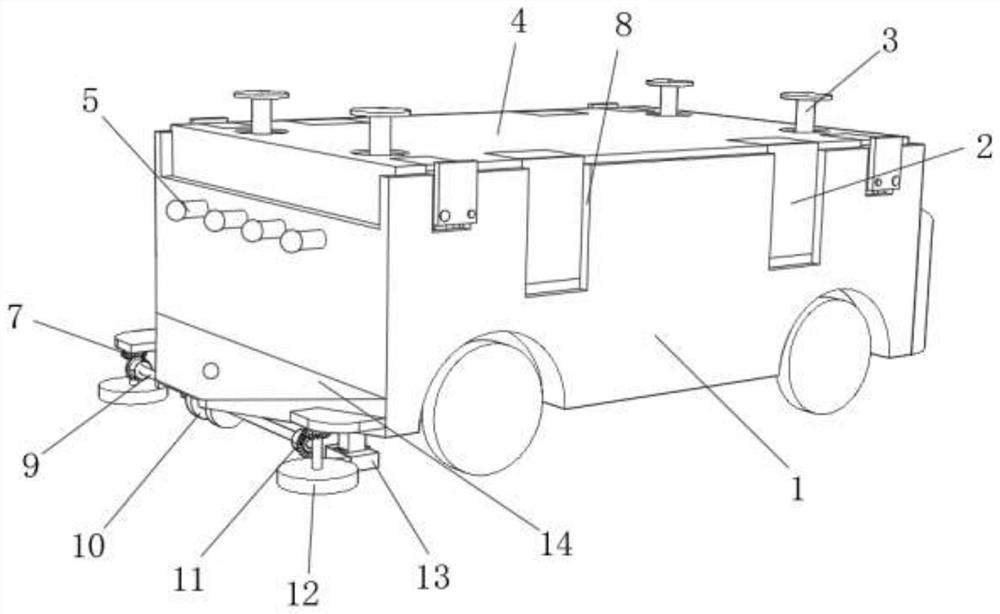

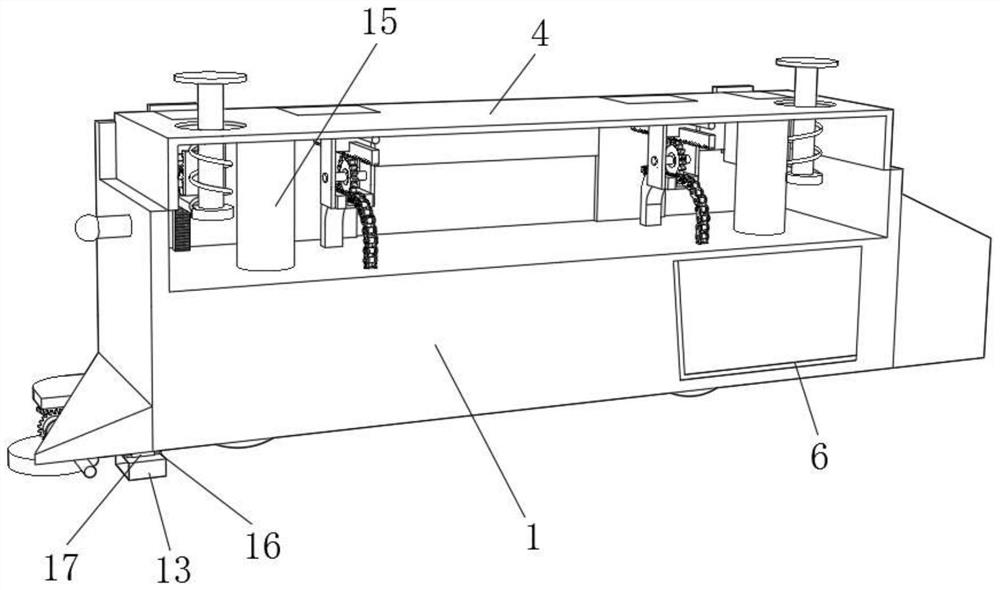

[0033] refer to Figure 1-Figure 5 , an automatic guided trolley for logistics transportation, including a car body 1, a plurality of electric telescopic rods 15 are fixed on the bottom inner wall of the car body 1 by bolts, and a top frame 4 is fixed on the top of the electric telescopic rods 15 by bolts. Both sides are provided with two notches 8, both sides of the car body 1 are provided with two extension mechanisms 2, the extension mechanism 2 includes a fixed frame 26, the fixed frame 26 is fixed on the bottom of the top frame 4 by bolts, the fixed frame 26 Two sliding holes are provided on one side of the sliding hole, and the first rack 25 and the guide rod 27 are slidably connected respectively in the slide holes. One end of the first rack 25 and the guide rod 27 is fixed with an extension plate 24 by bolts, and the fixing frame 26 One side is fixed with a connecting shaft by a bolt, and one side of the connecting shaft is rotatably connected with a first gear 28, and...

Embodiment 2

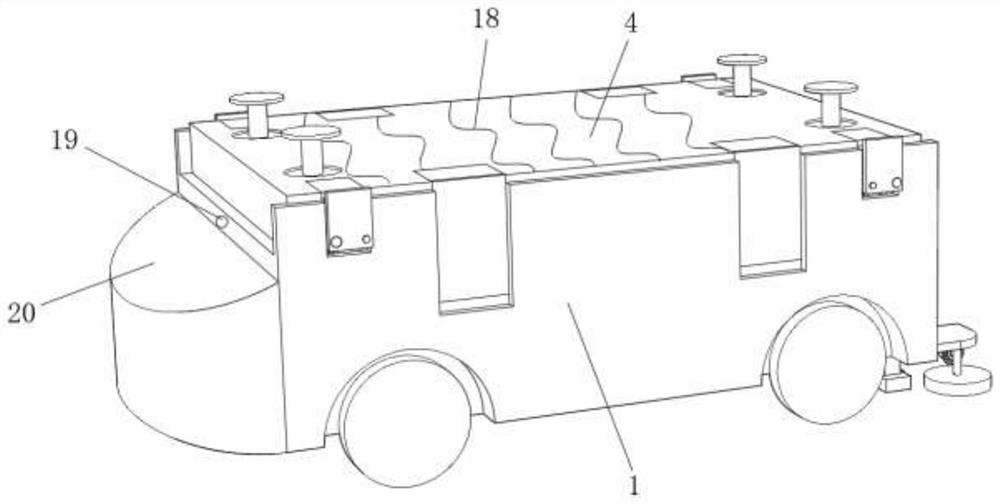

[0037] refer to Image 6 , an automatic guided trolley for logistics handling, also includes two first telescopic rods 41, the first telescopic rods 41 are fixed on the outer wall of one side of the car body 1 by bolts, and one end of the first telescopic rods 41 is fixed with a buffer plate by bolts 43. When the device collides with an external object, the object presses the buffer plate 43, causing the first telescopic rod 41 to shrink, thereby buffering the device and preventing the device from being damaged by the impact of an external object. One side of the first telescopic rod 41 The first spring 42 is sleeved, and the two ends of the first spring 42 are respectively fixed with the buffer plate 43 and the vehicle body 1. When the object leaves the buffer plate 43, the first spring 42 rebounds and elongates, thereby making the first telescopic Rod 41 elongates and resets.

[0038] The working principle of this embodiment: when the device is subjected to an external impa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com