Batching device for preparing high-strength gypsum a from industrial byproduct gypsum

A technology for industrial by-product gypsum and high-strength gypsum, which is applied to clay preparation devices, liquid batching supply devices, and unloading devices, etc. It can solve problems such as poor feeding, uneven mixing, and failure to meet batching requirements, and achieve auxiliary lifting The effect of output speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

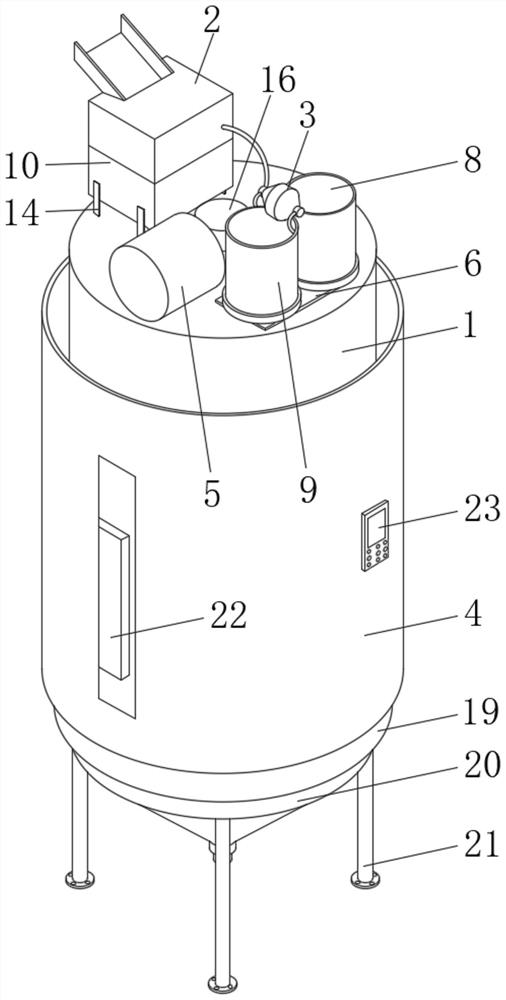

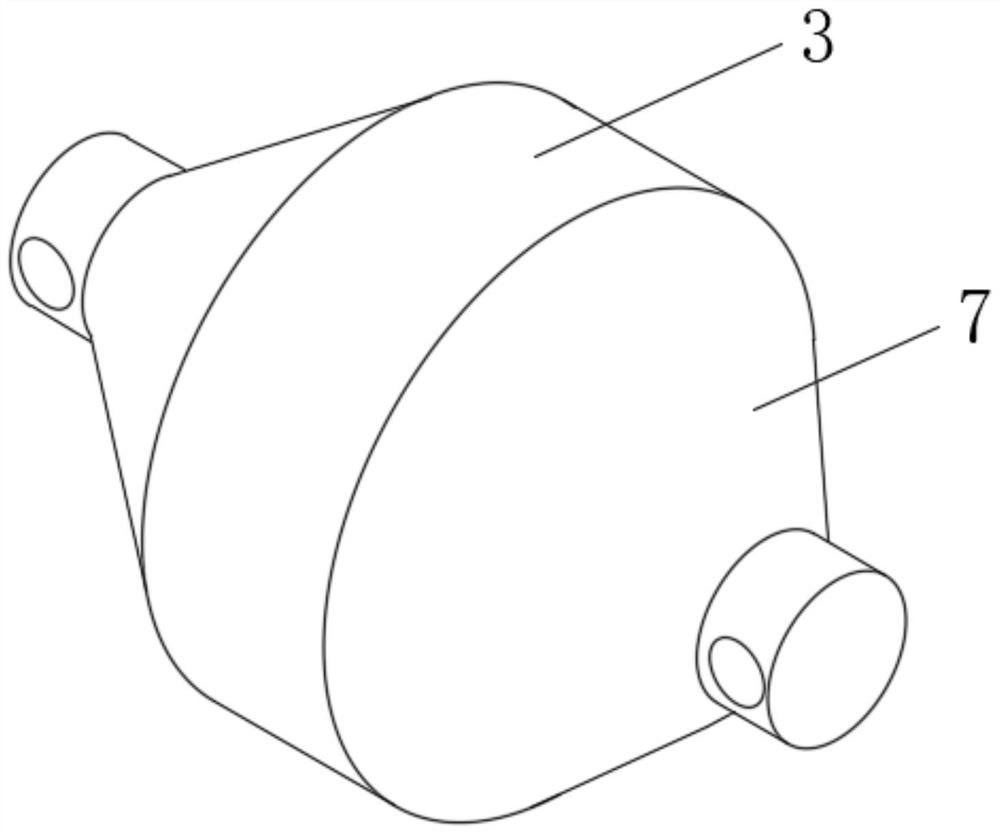

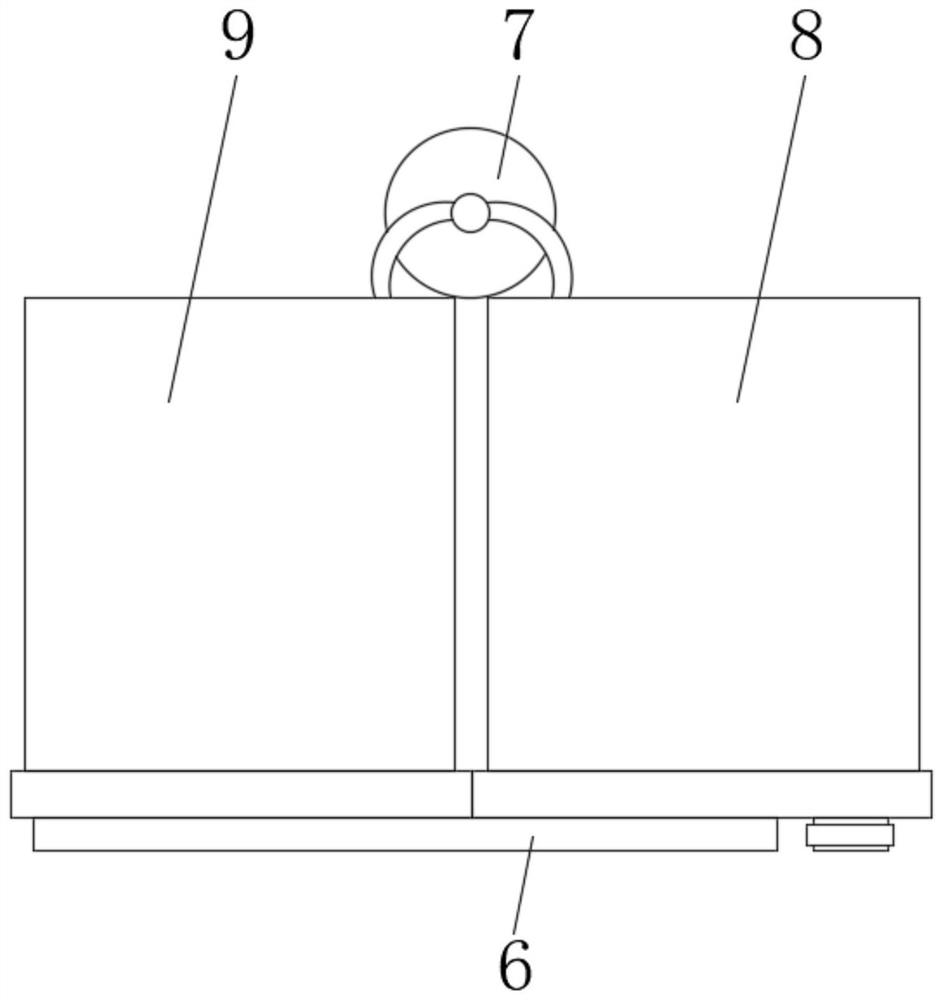

[0025] For agitation and dust removal, refer to the attached figure 1 , 2 and 3, the top of the mixing bucket 1 is connected with a pulverizer 2 through a communication mechanism, the top of the mixing bucket 1 is connected with a stirring mechanism and an air pressurizer 5, and the top of the mixing bucket 1 is connected with multiple sets of countersunk bolts Connected with a horizontal plate 6, the top of the horizontal plate 6 is provided with a water liquid barrel 8 and a reaction liquid barrel 9, and the tops of the water liquid barrel 8 and the reaction liquid barrel 9 are connected with an exhaust fan 3 by multiple sets of screws. Both sides of the exhaust fan 3 are connected with a ventilation bucket 7, and the ventilation bucket 7 on one side is connected with two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com