Preparation method of soldering paste for automobile control panel and homogenizing equipment of preparation method

A technology of automobile control and solder paste, applied in welding equipment, welding medium, metal processing equipment, etc., can solve problems such as high temperature oxidation, achieve the effects of homogenizing material particles, improving oxidation resistance, and anti-corrosion electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

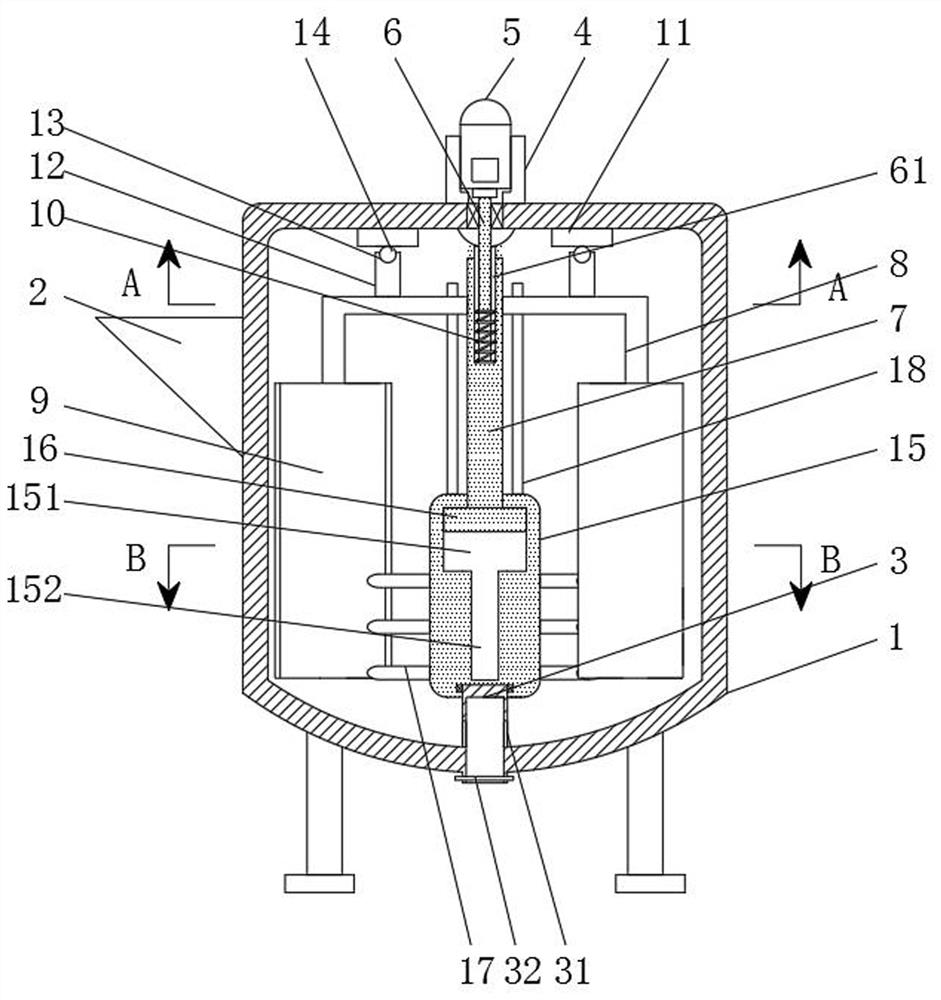

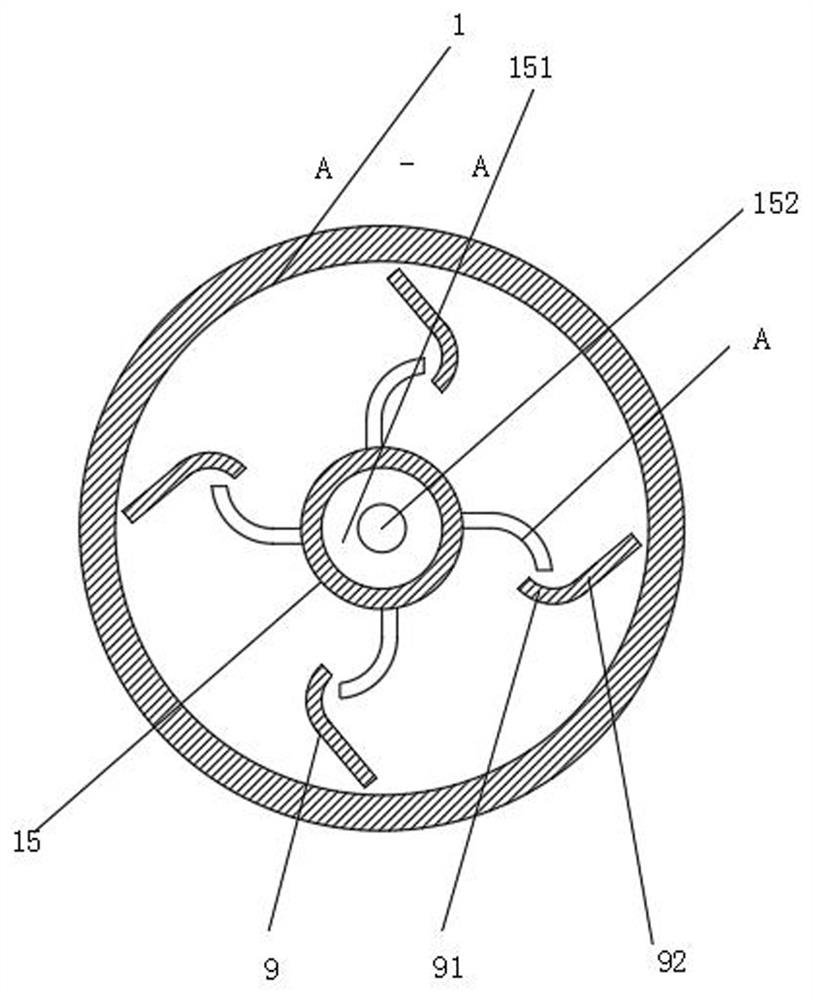

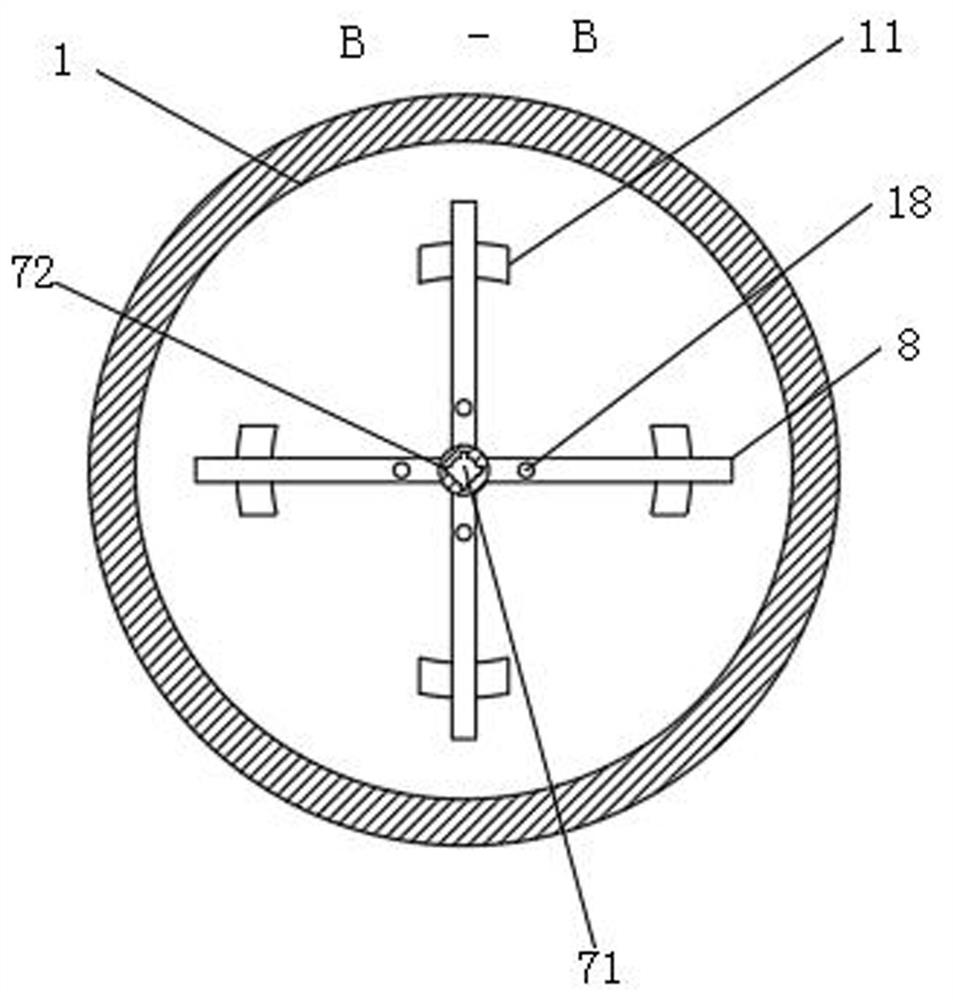

Image

Examples

Embodiment 1

[0031] An embodiment provided by the present invention: a preparation method of solder paste for an automobile control board:

[0032] The solder paste is made of tin powder and solder paste with a mass ratio of 85:15; among them, the tin powder includes the following components by weight: 5 parts of bismuth alloy solder powder, 85 parts of Sn-Ag-Cu series solder powder , 4 parts of nano-titanium particles and 6 parts of graphene, the solder paste is composed of the components in parts by weight: 30 parts of disproportionated rosin, 10 parts of surfactant, 35 parts of organic solvent, 15 parts of organic resin, 5 parts of zinc chloride servings and anti-aging agent 5;

[0033] The preparation method of solder paste comprises the following steps;

[0034] S1: Encapsulate the above-mentioned tin-bismuth alloy solder powder, Sn-Ag-Cu series solder powder and nano-titanium particles in a vacuum quartz tube, and then fill it with high-purity nitrogen protective gas;

[0035] S2: ...

Embodiment 2

[0043] The difference between the second embodiment and the first embodiment is that

[0044] In step S5, pour into a vacuum mixer and stir at a low speed for 12-18 minutes, then fill with nitrogen and stir at a medium speed for 50-60 minutes to obtain solder paste.

Embodiment 3

[0045] Embodiment 3 differs from Embodiment 1 in that

[0046] The solder paste is made of tin powder and solder paste with a mass ratio of 85:15; among them, the tin powder includes the following components by weight: 8 parts of bismuth alloy solder powder, 82 parts of Sn-Ag-Cu series solder powder , 4 parts of nano-titanium particles and 6 parts of graphene, and the described soldering paste is composed of each component in parts by weight: 45 parts of disproportionated rosin, 8 parts of surfactant, 32 parts of organic solvent, 5 parts of organic resin, chlorinated Zinc 5 parts and anti-aging agent 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com