Bifunctional soybean-derived polypeptide and preparation method thereof

A dual-function, dual-function technology, applied in the field of functional peptides, can solve the problem of less bifunctional peptides, and achieve the effects of long storage period, broad market application prospects, and simple and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

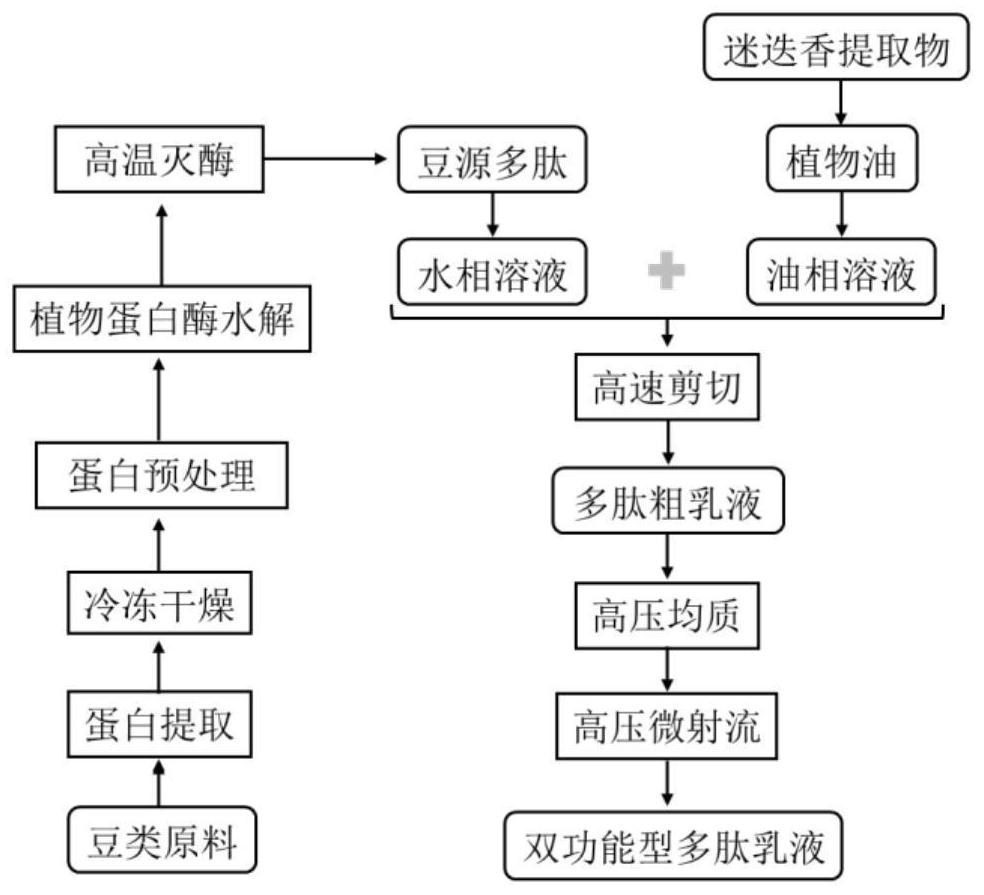

[0066] Example 1: A method for preparing bifunctional black soybean polypeptide

[0067] This embodiment mainly includes the following steps:

[0068] (1) Extraction of isolated protein from soybean sources: crush and sieve black soybeans, add 3 times the volume of n-hexane to degrease; dissolve defatted black soybean powder in deionized water, adjust the pH of the solution to 9.0 with sodium hydroxide, stir at 30°C for 1.5 hours, and take it by centrifugation Then use hydrochloric acid to adjust the pH to 4.0, repeat the above steps twice, centrifuge at 10,000 rpm for 10 minutes to collect the protein precipitate, wash the precipitate with deionized water until neutral, and finally freeze-dry to obtain black soybean protein isolate.

[0069] (2) Infrared treatment: The protein obtained above was subjected to infrared heat treatment, the infrared temperature was 120° C., and the treatment time was 20 minutes.

[0070] (3) Polypeptide preparation: Dissolve infrared protein pow...

Embodiment 2

[0072] Example 2: A method for preparing bifunctional mung bean polypeptide

[0073] This embodiment mainly includes the following steps:

[0074] (1) Extraction of isolated protein from bean sources: crush and sieve mung beans, add 4 times the volume of n-hexane to degrease; dissolve defatted mung bean powder in deionized water, adjust the pH of the solution to 8.5 with sodium hydroxide, stir at room temperature for 2 hours, centrifuge and take the supernatant for reuse Adjust the pH to 4.5 with hydrochloric acid, repeat the above steps twice, centrifuge at 10,000 rpm for 10 minutes to collect the protein precipitate, wash the precipitate with deionized water until neutral, and finally freeze-dry to obtain mung bean protein isolate.

[0075] (2) Infrared treatment: The protein obtained above was subjected to infrared heat treatment, the infrared temperature was 100° C., and the treatment time was 25 minutes.

[0076] (3) Polypeptide preparation: Mung bean protein powder is d...

Embodiment 3

[0078] Example 3: A method for preparing bifunctional red bean polypeptide

[0079] This embodiment mainly includes the following steps:

[0080] (1) Extraction of isolated protein from bean source: crush and sieve red beans, add 4 times the volume of n-hexane to degrease; dissolve defatted red bean powder in deionized water, adjust the pH of the solution to 9.0 with sodium hydroxide, stir at room temperature for 2 hours, centrifuge and take the supernatant for reuse Adjust the pH to 4.3 with hydrochloric acid, repeat the above steps twice, centrifuge at 10,000 rpm for 10 minutes to collect the protein precipitate, wash the precipitate with deionized water until neutral, and finally freeze-dry to obtain the red bean protein isolate.

[0081] (2) Infrared treatment: The protein obtained above was subjected to infrared heat treatment, the infrared temperature was 100° C., and the treatment time was 20 minutes.

[0082] (3) Polypeptide preparation: red bean protein powder is dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

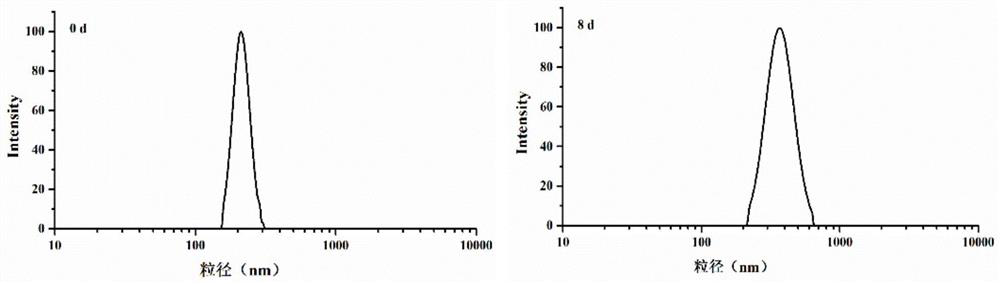

| emulsifying | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com