Hub ventilation and heat dissipation device

A ventilation and heat dissipation, hub technology, which is applied to wind turbines, wind power generation, wind turbines, etc. in the same direction as the wind, and can solve problems such as operational accidents, corrosion of hub connection structures, and large power dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

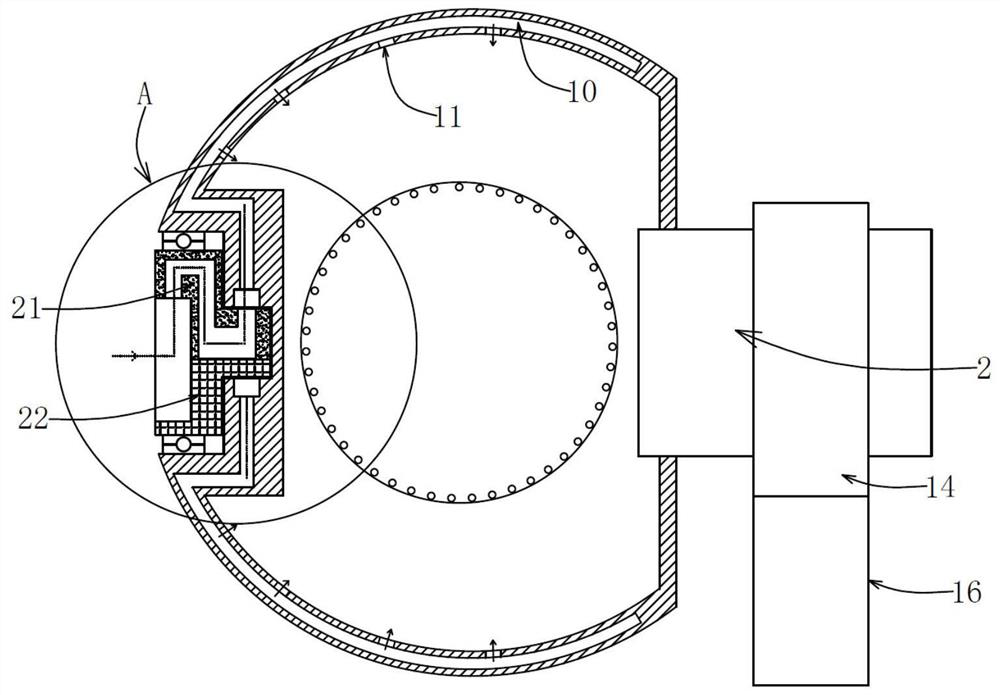

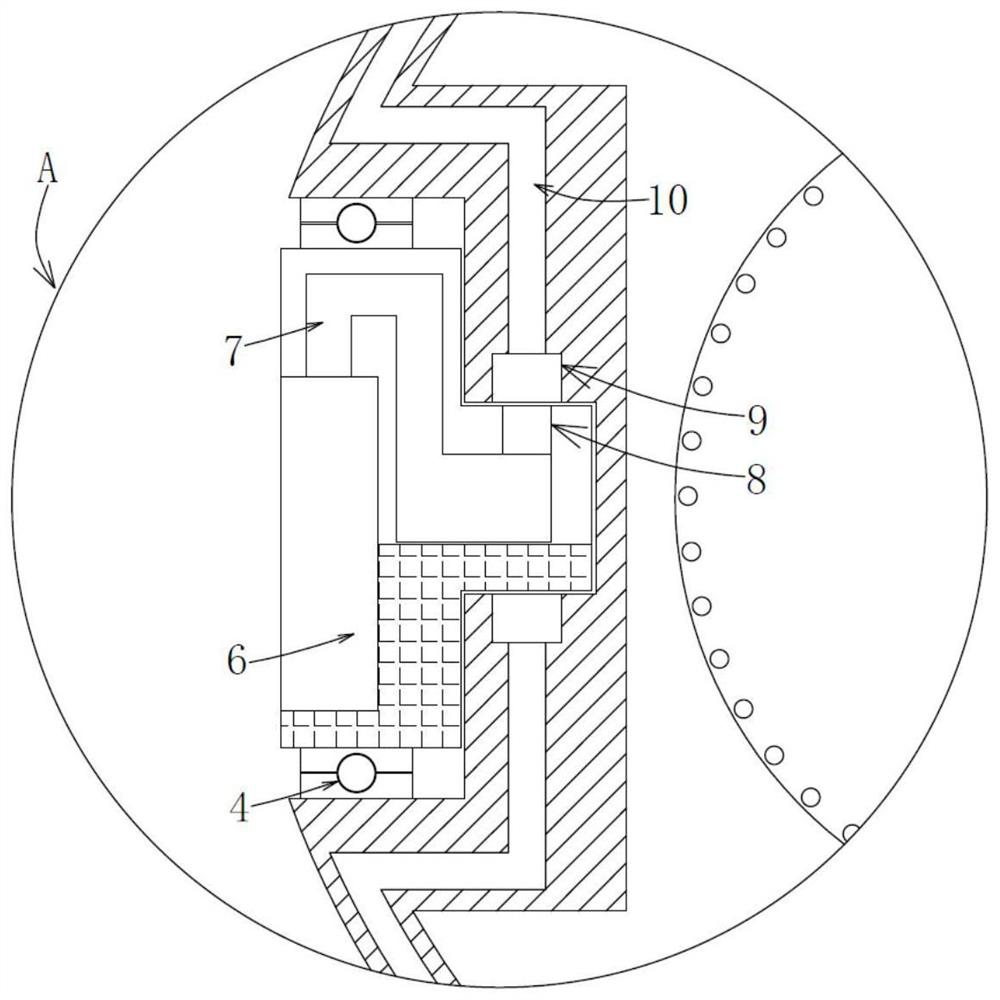

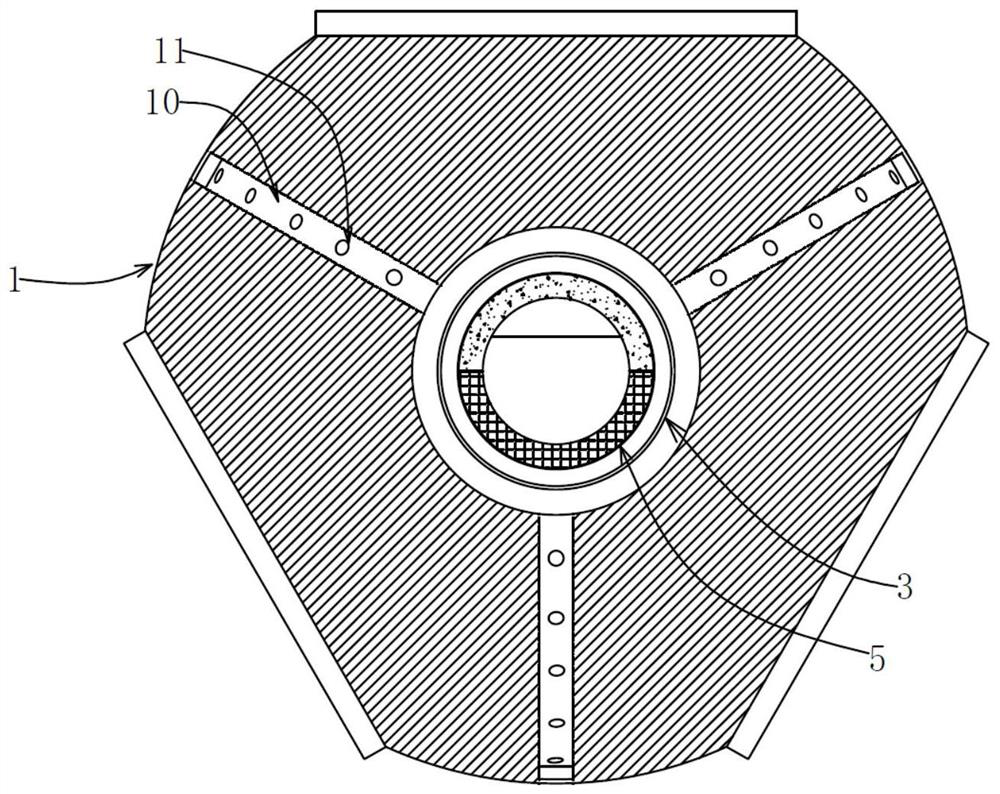

[0027] see Figure 1-6 , the present invention provides a technical solution:

[0028] A wheel hub ventilation and heat dissipation device, comprising a wheel hub 1, a wind wheel shaft 2 is fixedly installed on the back side of the wheel hub 1, an air inlet groove 3 is opened on the windward side of the wheel hub 1, and a gravity offset ring is movably installed in the air inlet groove 3 through an offset bearing 4 5. There is a windward slot 6 in the gravity offset ring 5, and an S-shaped air inlet channel 7 is opened on the upper part of the windward slot 6, which runs through the rotation axis. The side of the gravity offset ring 5 has an S-shaped air inlet The air intake hole 8 through which the road 7 runs;

[0029] The mass distribution of the gravity deflection ring 5 of the present invention is uniform due to the substance filled inside. When the hub 1 rotates during the power generation process, the gravity deflection ring 5 maintains a fixed angle under the action o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com