Grouting reinforcement method for deformation control of subway subsurface tunnel underneath-passing operation subway interval

A technology of grouting reinforcement and deformation control, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of structural safety, complexity and long duration affecting surrounding structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

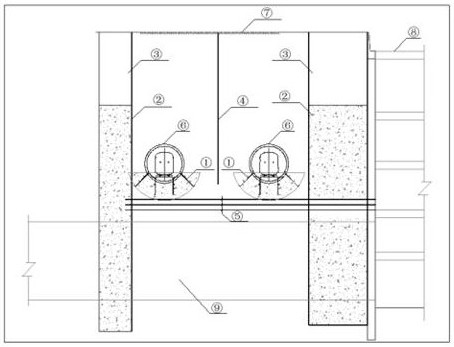

[0024] The present invention is further described below in conjunction with accompanying drawing.

[0025] like figure 1 , 2 As shown, a grouting reinforcement method for the deformation control of the underground excavation tunnel passing under the operating subway section includes the following steps:

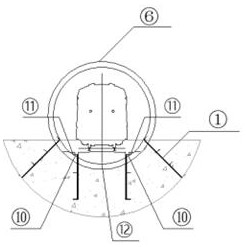

[0026] 1) Before the submerged tunnel passes through, pre-grout the tunnel base through the existing line section ⑥ ballast bed structure ① to improve the homogeneity of the rock and soil, increase the anti-sinking tensile and shear stress of the rock and soil, and limit the vertical direction of the existing line. deformation;

[0027] 2) Before the underground excavation tunnel goes under, after the pre-grouting reinforcement of the tunnel base ① is completed, the outer side of the existing line section is pre-reinforced ② through the ground ⑦ to improve the deformation resistance of the rock and soil and limit the lateral displacement of the existing line;

[0028] 3) D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com