Drill rod heating device for rotary drilling rig in high and cold region and heating method of heating device

A technology of heating device and rotary drilling rig, applied in drilling equipment and methods, isolation device, drilling equipment and other directions, can solve problems such as affecting the construction of drilled piles and easy freezing of drill pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

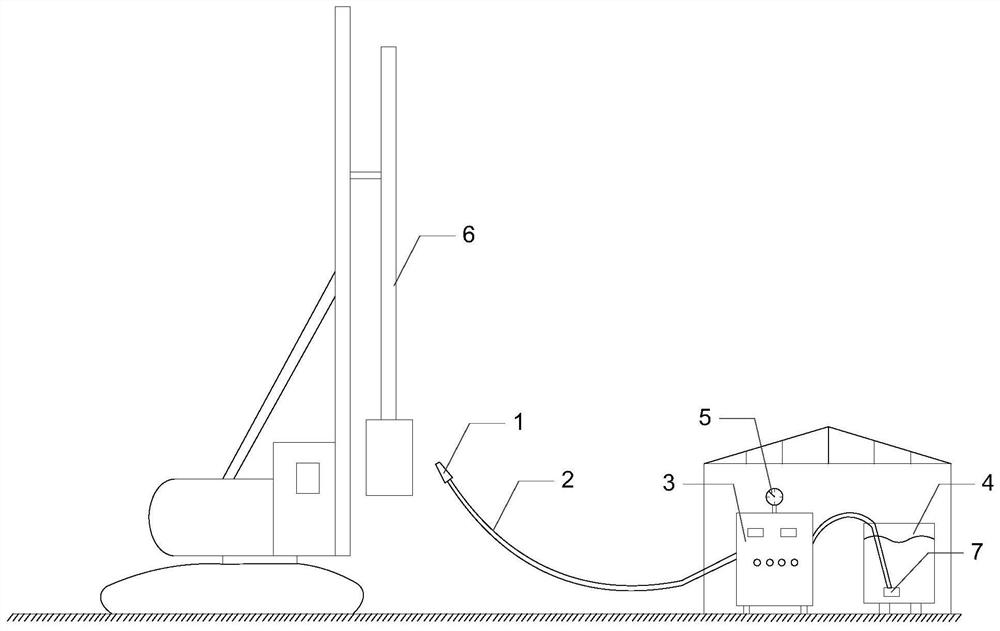

[0017] Specific implementation mode one: combine figure 1 Describe this embodiment, the drill pipe heating device of a rotary drilling rig in an alpine region described in this embodiment is used to heat the drill pipe 6 under construction; the heating device includes a handle nozzle 1, a connecting pipe 2, a steam engine 3 and a water tank 4;

[0018] The steam engine 3 is used to convert water into high-temperature steam, and the steam engine 3 is provided with a water inlet and a steam outlet; the water inlet of the steam engine 3 is connected with the water outlet of the water tank 4, and the water tank 4 is used for storing water; the steam outlet of the steam engine 3 It communicates with one end of the connecting pipe 2, and the other end of the connecting pipe 2 communicates with the air inlet of the handle nozzle 1; the air outlet of the handle nozzle 1 is close to the heating part of the drill pipe 6;

[0019] The handle spray head 1 is provided with a handle.

[0...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment further defines the drill rod heating device of a rotary drilling rig in an alpine region described in Embodiment 1. In this embodiment, the heating device also includes a pressure gauge 5;

[0022] The pressure gauge 5 is arranged on the steam engine 3 and is used for monitoring the pressure of the high-temperature steam ejected from the steam outlet of the steam engine 3 .

[0023] In this embodiment, by adding a pressure gauge 5, it is convenient to monitor the pressure of the high-temperature steam generated by the steam engine 3, so that it is convenient to control the speed of the high-temperature steam ejected from the steam outlet of the steam engine 3.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment is to further limit the drill pipe heating device of a rotary drilling rig in the alpine region described in Embodiment 1. In this embodiment, the connecting pipe 2 is a hose made of rubber .

[0025] In this embodiment, the connecting pipe 2 is a hose made of rubber, which is easy to bend and move, so as to adapt to different construction environments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com