Building equipment capable of assisting in building wall construction and using method thereof

A technology for building equipment and building walls, which is applied in the processing of building materials, construction, machinery and equipment, etc., and can solve the problems of inability to flexibly adjust the thickness of laying materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

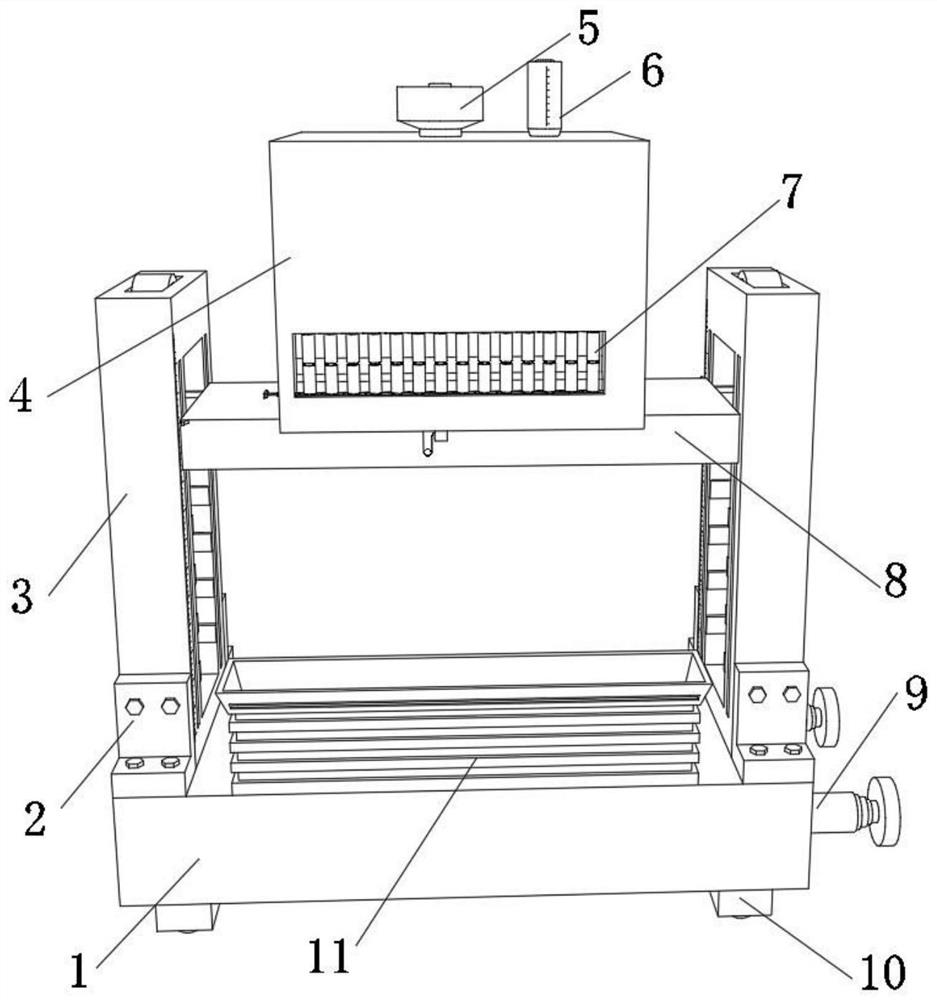

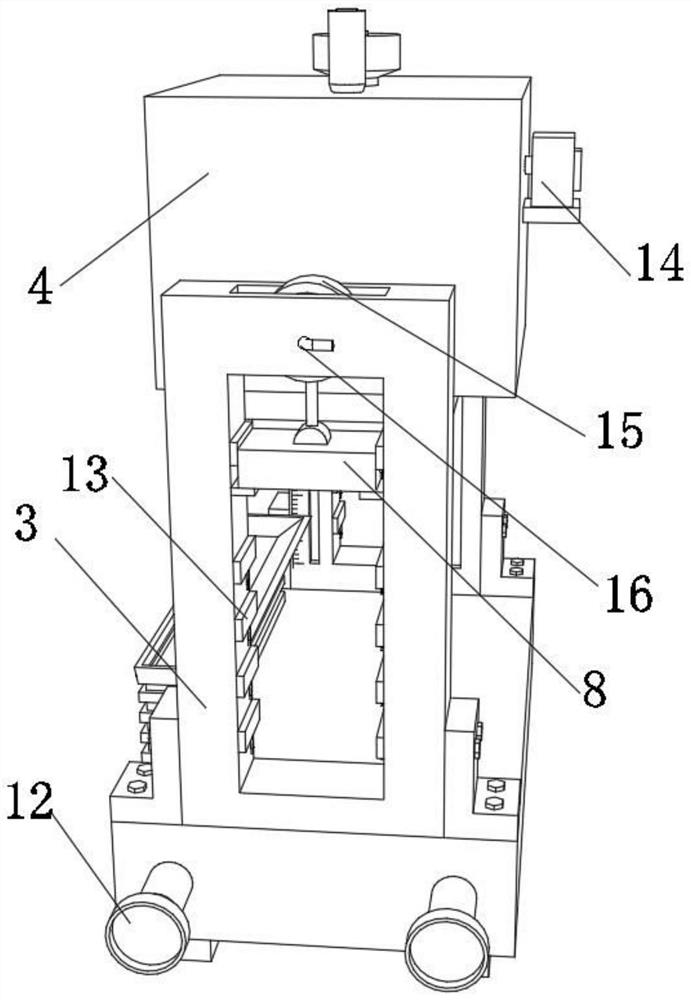

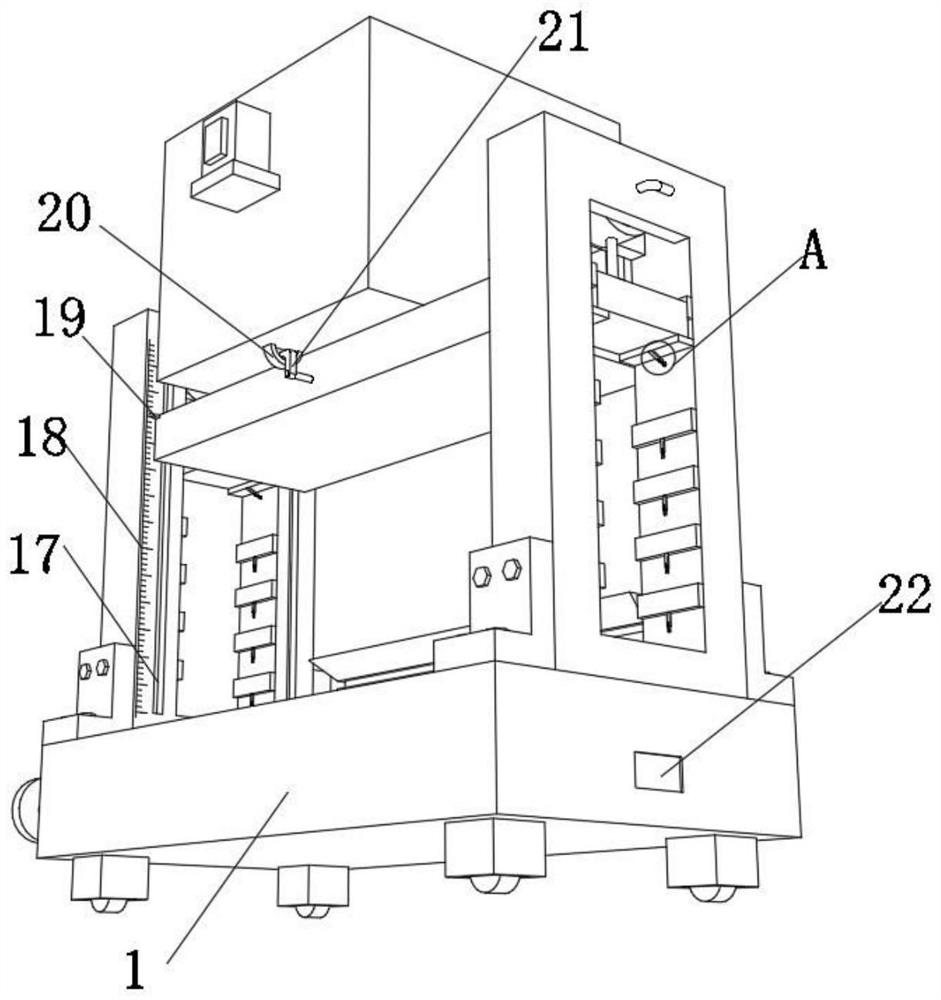

[0044] A construction equipment that can assist in the construction of building walls, such as figure 1 , figure 2 , Figure 4-6 and Figure 8 Shown, comprise base 1 and material box 4, one side outer wall of described material box 4 is provided with discharge opening 23, and the top inner wall of discharge opening 23 and the bottom inner wall all offer moving groove 25, two moving grooves 25 The inner wall is slidingly connected with a plurality of rolling brushes 7, and the top and bottom ends of the plurality of rolling brushes 7 are rotatably connected with an adjustment assembly 24. The adjustment assembly 24 consists of a scissor plate and a collar. Consistent, the outer walls of one side of the two adjustment assemblies 24 are respectively fixed to the inner wall of one side of the discharge port 23 by bolts, and the outer walls of the adjustment assemblies 24 are fixed with a limit adjustment rod 37 by bolts, and one end of the limit adjustment rod 37 is inserted in...

Embodiment 2

[0050] A construction equipment that can assist in the construction of building walls, such as figure 1 and Figure 4 As shown, this embodiment makes the following improvements on the basis of embodiment 1: the inner wall of one side of the discharge port 23 is fixed with a telescopic plate by bolts. After adjusting the distance between a plurality of rolling brushes 7, if the distance between a plurality of rolling brushes 7 is small, a certain range of openings will leak out from one side of the discharge port 23. At this time, manually push the telescopic plate to block it Openings, so as to avoid material falling from the openings during construction.

[0051] In this embodiment, the front working principle is the same as that of Embodiment 1. After adjusting the distance between the multiple rolling brushes 7, if the distance between the multiple rolling brushes 7 is small, a certain range will be leaked from one side of the discharge port 23. At this time, manually pus...

Embodiment 3

[0053] A method for using the building equipment described in Embodiment 1 that can assist building wall construction, such as Figure 1-8 shown, including the following steps:

[0054] S1: Adjust the position of the material box 4 on the fixing seat 8 and fix the material box 4 according to the position of the construction wall;

[0055] S2: Add materials from feed port one 5 and feed port two 6, and the materials are crushed by the dispersion and sieve structure into the material box 4, and stirred and mixed;

[0056] S3: According to the horizontal position of the wall surface to be constructed, adjust the height of the fixed seat 8 and the material box 4 on it, and adjust the bearing plate 13 to support the fixed seat 8;

[0057] S4: According to the laying thickness requirements of the project, the control equipment moves to a distance equal to the laying thickness and fixes the position;

[0058] S5: Use the limit adjustment rod 37 to adjust the spacing density of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com