Deep-cold-rolled steel plate with high product of strength and elongation and preparation method

A technology of rolling steel plates and high-strength plastic products, applied in the direction of temperature control, etc., can solve problems affecting the transverse and longitudinal properties of steel plates, and achieve the effects of strengthening work hardening ability, improving strong plastic properties, and increasing yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in more detail through examples below. These examples are only descriptions of the best implementation modes of the present invention, and do not limit the scope of the present invention in any way.

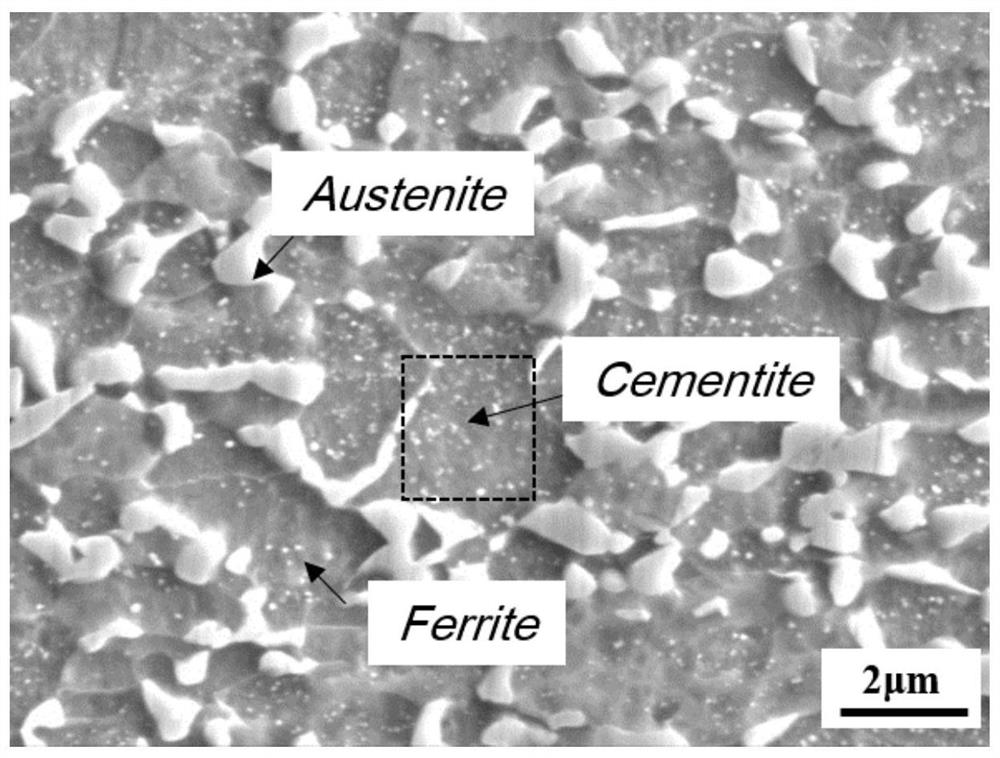

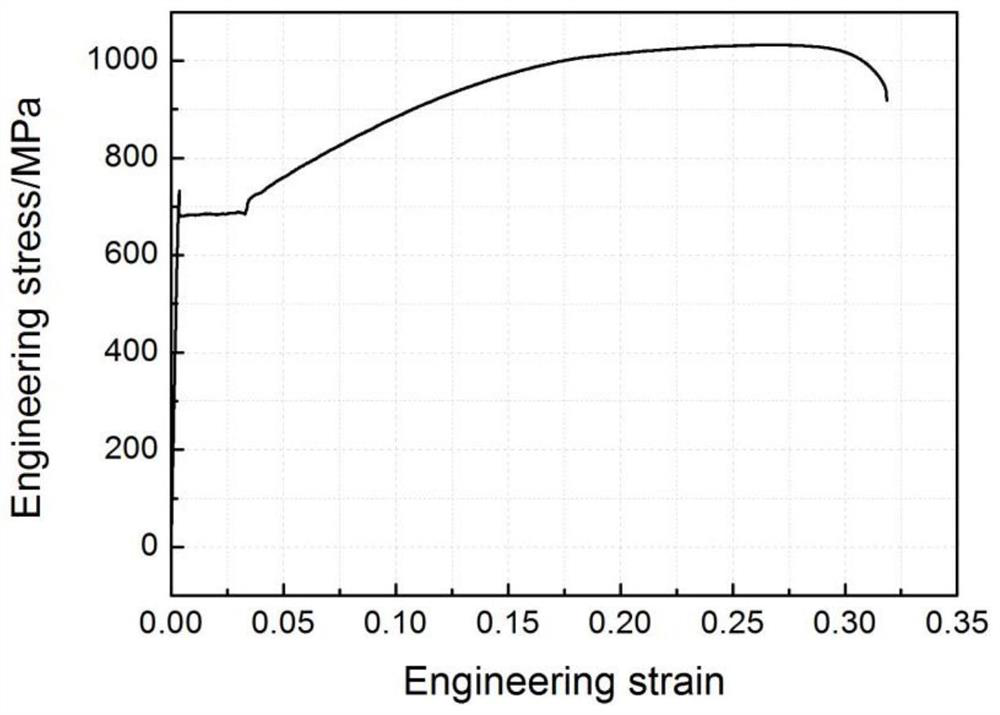

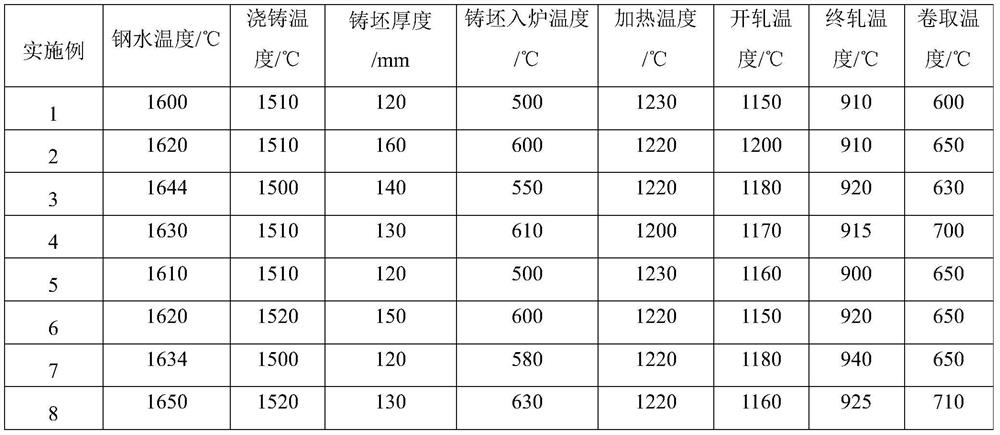

[0045] The chemical composition of embodiment steel has been listed in table 1, and table 2 has listed the continuous casting of embodiment steel and hot rolling process parameter, and table 3 has listed the process parameter of embodiment steel cold rolling and continuous annealing, and table 4 gives The mechanical properties of the steels of the examples are shown, and Table 5 shows the final proportions of each phase of the steels of the examples. Among them, Examples 1-8 are cryogenically rolled steel (using the invented cryogenic rolling process), and Examples 9-10 are comparative examples (using ordinary cold rolling process).

[0046] Chemical composition of table 1 embodiment steel, wt%

[0047] C mn Cr Si A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com