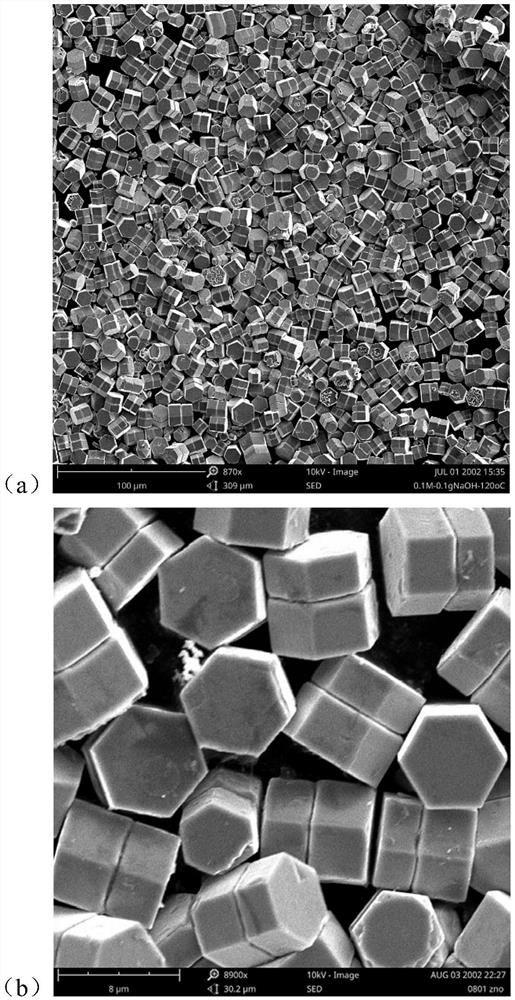

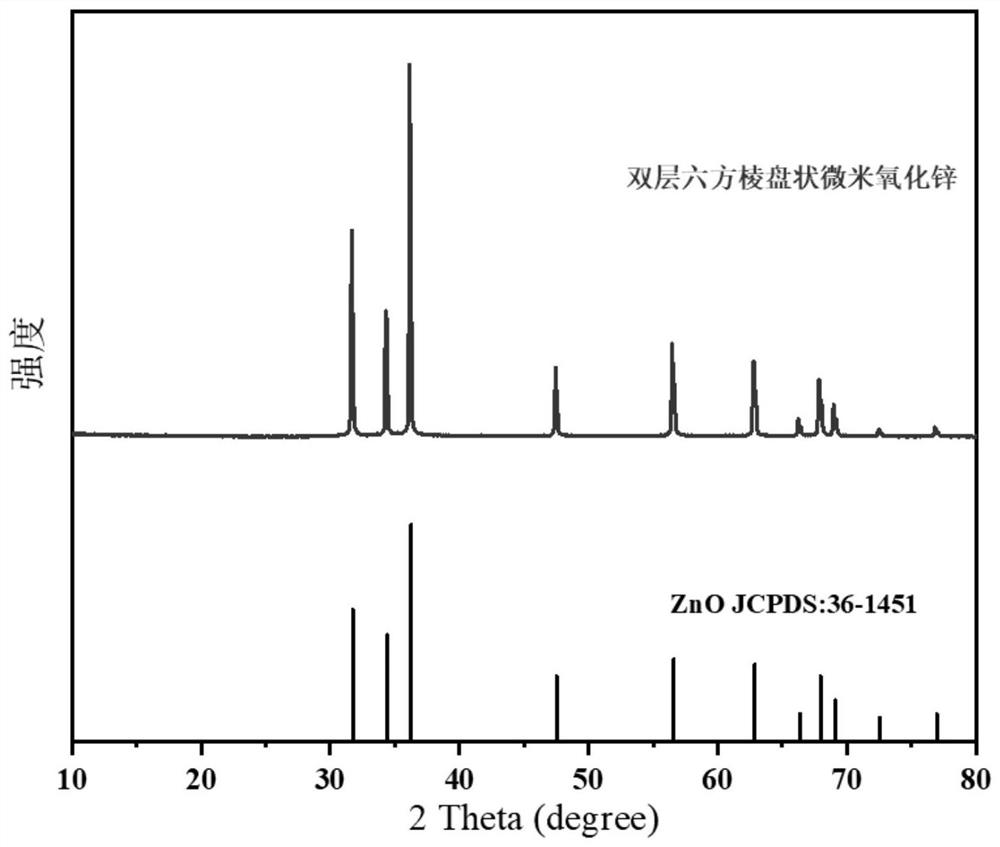

Controllable double-layer prismatic-disc-shaped micron zinc oxide and preparation method thereof

A zinc oxide and manufacturing method technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of exposed crystal planes, uncontrollable adjustment of product structure, poor crystallinity, etc., and achieve short time, good crystallinity, and improved The effect of crystallization properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0036] Specific embodiment one: present embodiment a kind of preparation method of controllable double-layer prismatic disk micron zinc oxide. The preparation method described in this embodiment can prepare double-layer hexagonal prismatic disc-shaped micron zinc oxide with special structure and properties, which is specifically completed in the following steps:

[0037]1. Prepare a uniform reactant solution: Disperse the zinc source in a mixed solvent of alcohol and water under magnetic stirring, then slowly add the prepared alkali solution to the zinc source solution dropwise, and after the dropwise addition, place it at room temperature (5~40°C) react for a period of time, keep stirring during the dropping process and the reaction process; 2. Hydrothermal reaction: pour the mixed solution into the lining of the hydrothermal reaction kettle, then put it into the hydrothermal reaction kettle and put it in a heating oven Wait for heating in the heating equipment, the reaction ...

Embodiment 1

[0050] A method for preparing controllable double-layer prismatic micron zinc oxide, which is specifically completed according to the following steps:

[0051] 1. Prepare a uniform reactant solution: Dissolve 6mmol of zinc acetate in a mixed solution of 80mL of water and ethanol, including 50mL of water and 30mL of ethanol, and ultrasonically disperse it for 10 minutes, then move it to a magnetic stirring table with a speed of 500rpm , at 25°C, slowly add sodium hydroxide solution (0.25mol / L, 10mL) dropwise to the above solution for metathesis reaction, the rate of addition is 1min / mL, during the process of adding, the solution changes from transparent to milky white After the turbid liquid is added dropwise, continue to stir for 5 minutes; wherein, the mass ratio of zinc acetate to sodium hydroxide is 2.4:1; the reactant solution is obtained after the double decomposition reaction; 2. Hydrothermal treatment: pour the obtained reactant solution Put it into a 100mL hydrothermal...

Embodiment 2

[0056] A method for preparing controllable double-layer prismatic micron zinc oxide, which is specifically completed according to the following steps:

[0057] 1. Prepare a uniform reactant solution: Take 6 mmol of zinc acetate dihydrate and dissolve it in a mixed solution of 30 mL of water and ethanol, including 20 mL of water and 10 mL of ethanol, and ultrasonically disperse it evenly for 10 minutes, then move to a magnetic stirrer with a speed of 500 rpm On the platform, at 25°C, slowly add sodium hydroxide solution (0.15mol / L, 10mL) to the above solution for metathesis reaction. It is a milky white turbid liquid. After the dropwise addition, continue to stir for 5 minutes; wherein, the mass ratio of zinc acetate dihydrate to sodium hydroxide is 4:1; the reactant solution is obtained after the double decomposition reaction; 2. Hydrothermal treatment: the obtained Pour the reactant solution into the lining of a 50mL hydrothermal reaction kettle, put it into the hydrothermal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com