Gradient isomeric titanium-tantalum layered composite material and preparation method and application thereof

A layered composite material, titanium and tantalum technology, applied in the field of biomedical materials, can solve the problems of high manufacturing cost, incompatibility of high strength and high fracture toughness, complex manufacturing process, etc., to achieve reduced elastic modulus, good mechanical properties, good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

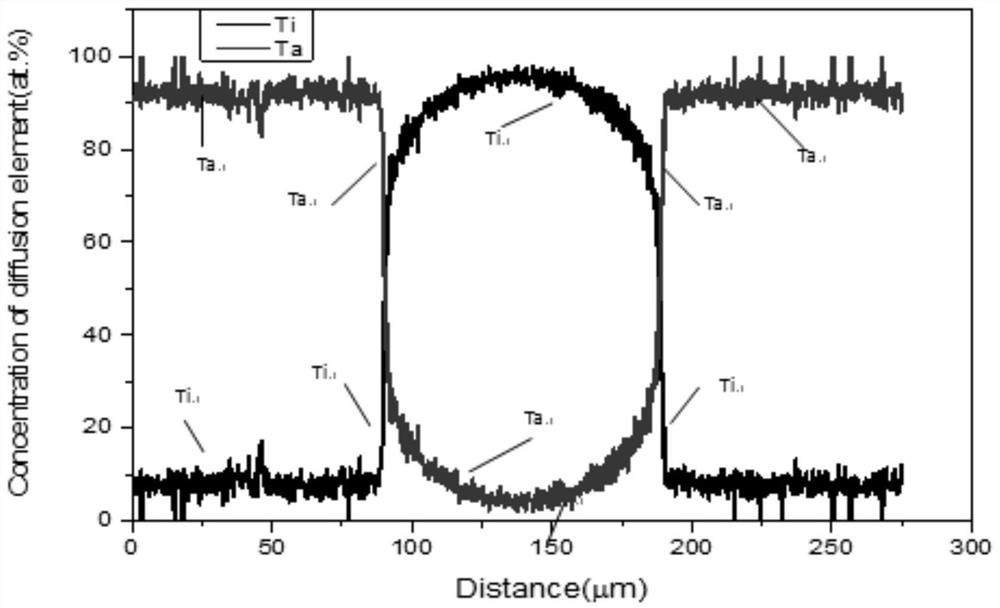

[0047] The titanium layer and the tantalum layer prepared by a gradient heterogeneous titanium / tantalum layered composite material described in this example are all made of rolled state metal sheets; figure 1 The graphics shown are superimposed; the 13th layer of 0.1mm titanium is the symmetrical layer, and the thickness and structure design of other layers are symmetrical about the 13th layer of 0.1mm titanium, and the 13th layer of 0.1mm titanium is stacked 0.1mm from the inside to the outside. Titanium / 0.03mm tantalum / 0.1mm tantalum / 0.1mm tantalum / 0.1mm tantalum / 0.05mm tantalum / 0.1mm tantalum / 0.03mm tantalum / 0.1mm tantalum / 0.05mm tantalum / 0.1mm tantalum / 0.1mm tantalum / 0.1mm tantalum.

[0048] In this embodiment, the preparation method of the gradient heterogeneous titanium-tantalum layered composite material with different thickness of tantalum layer is as follows:

[0049] Step 1: Surface Preparation

[0050]Manually cut 0.1mm thick titanium foil, 0.1mm tantalum foil, 0.0...

Embodiment 2

[0067] The titanium layer and the tantalum layer prepared by a gradient heterogeneous titanium / tantalum layered composite material described in this example are all made of rolled state metal sheets; figure 1 The graphics shown are superimposed; the 13th layer of 0.1mm titanium is the symmetrical layer, and the thickness and structure design of other layers are symmetrical about the 13th layer of 0.1mm titanium, and the 13th layer of 0.1mm titanium is stacked 0.1mm from the inside to the outside. Titanium / 0.03mm tantalum / 0.1mm tantalum / 0.1mm tantalum / 0.1mm tantalum / 0.05mm tantalum / 0.1mm tantalum / 0.03mm tantalum / 0.1mm tantalum / 0.05mm tantalum / 0.1mm tantalum / 0.1mm tantalum / 0.1mm tantalum.

[0068] In this embodiment, the preparation method of the gradient heterogeneous titanium-tantalum layered composite material with different thickness of tantalum layer is as follows:

[0069] Step 1: Surface Preparation

[0070] Manually cut 0.1mm thick titanium foil, 0.1mm tantalum foil, 0....

Embodiment 3

[0087]In this embodiment, the titanium layer and the tantalum layer prepared by a gradient heterogeneous titanium / tantalum layered composite material are both made of rolled metal sheets; sequentially stacked according to the graphics shown in claim 1; The 0.1mm titanium layer is a symmetrical layer, and the thickness and structural design of other layers are symmetrical about the 13th layer of 0.1mm titanium, and 0.1mm titanium / 0.03mm tantalum / 0.1mm titanium / 0.1 mm tantalum / 0.1mm titanium / 0.05mm tantalum / 0.1mm tantalum / 0.03mm tantalum / 0.1mm tantalum / 0.05mm tantalum / 0.1mm tantalum / 0.1mm tantalum / 0.1mm tantalum.

[0088] The preparation method of a gradient heterogeneous titanium / tantalum layered composite material in this embodiment is as follows:

[0089] Step 1: Surface Preparation

[0090] Manually cut 0.1mm thick titanium foil, 0.1mm tantalum foil, 0.05mm tantalum foil, and 0.03mm tantalum foil into Φ30mm discs, then polish the oxide attached to the lower surface with SiC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com