3D printer interlayer reinforced composite material adding device and 3D printer nozzle

A 3D printer and composite material technology, applied in the direction of additive processing, supply device, ceramic molding machine, etc., can solve the problems of weak interlayer, limited use in low temperature environment, etc., to achieve the effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

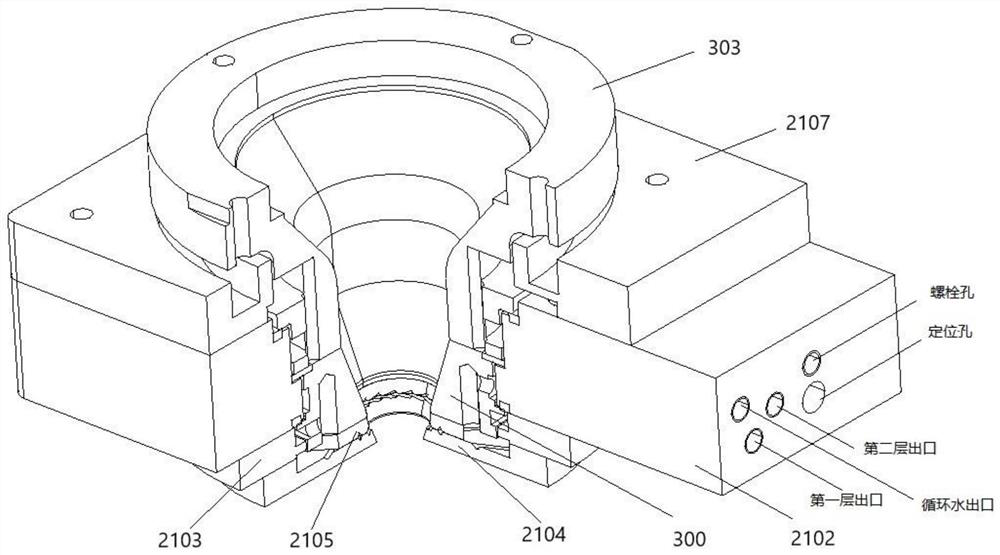

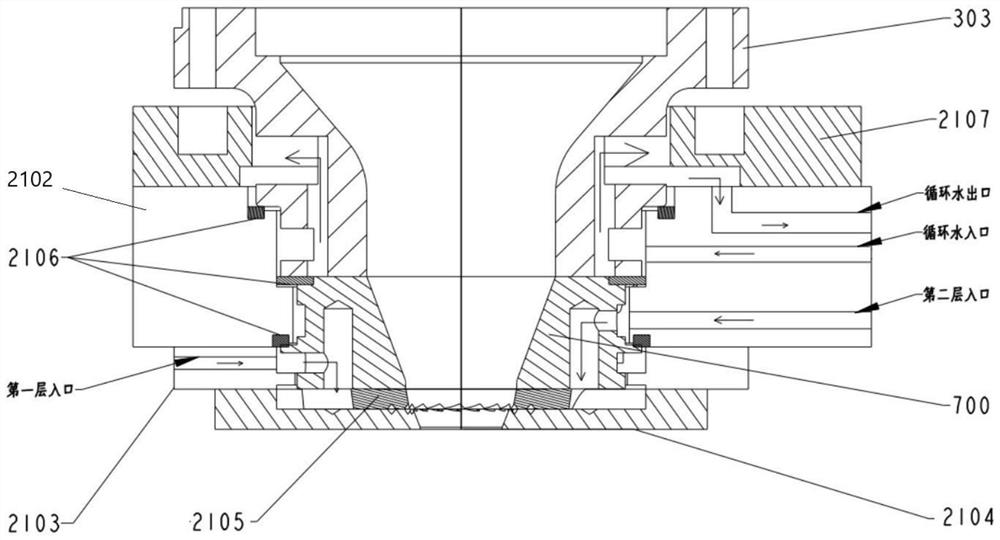

[0038] Such as figure 2 , 3 As shown, the 3D printer interlayer reinforced composite material adding device provided by the embodiment of the present invention includes: a constant temperature water integration board 2102 , a water retaining board 2107 , a grinding board 2104 and a roller ring 2105 .

[0039] The constant temperature water integrated board 2102 is sleeved outside the bottom drum 303 and the spatula nozzle 700 of the 3D printer; the front end of the constant temperature water integrated board 2102 is provided with a front support panel 2101 to enhance the stability of positioning and at the same time to block the splashes during printing out of the water droplets for added safety. The constant temperature water integration plate 2102 is provided with a circulating water inlet and a circulating water outlet, and a constant temperature water circulation channel is provided between the constant temperature water integration plate 2102 and the bottom drum 303 . ...

Embodiment 2

[0049] Such as Figure 5 As shown, the 3D printer nozzle provided by the embodiment of the present invention includes: an upper drum 301, a display drum 302, a bottom drum 303, an upper transmission shaft tube 400, a lower transmission shaft tube 500, a spatula nozzle 700 and the present invention The 3D printer interlayer reinforced composite material adding device provided by any embodiment.

[0050] The upper end drum 301 is connected to the display drum 302, the bottom drum 303 is arranged outside the lower part of the display drum 302, and the spatula mouth 700 is arranged at the bottom of the bottom drum 303; the upper end drum 301, the display drum 302 , the bottom drum 303 forms the drum 300 . The interlayer reinforced composite material adding device of the 3D printer is sleeved outside the bottom drum 303 and the spatula mouth 700;

[0051] The upper transmission shaft tube 400 is connected to the lower transmission shaft tube 500 and passes through the nozzle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com