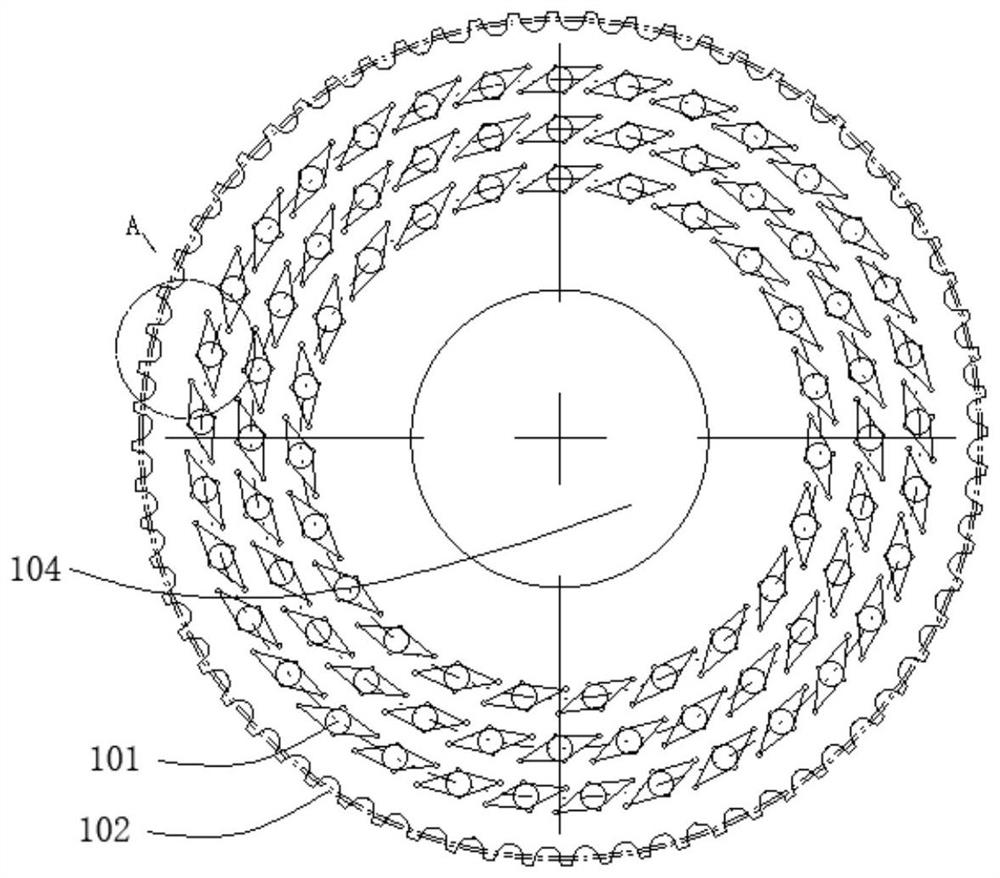

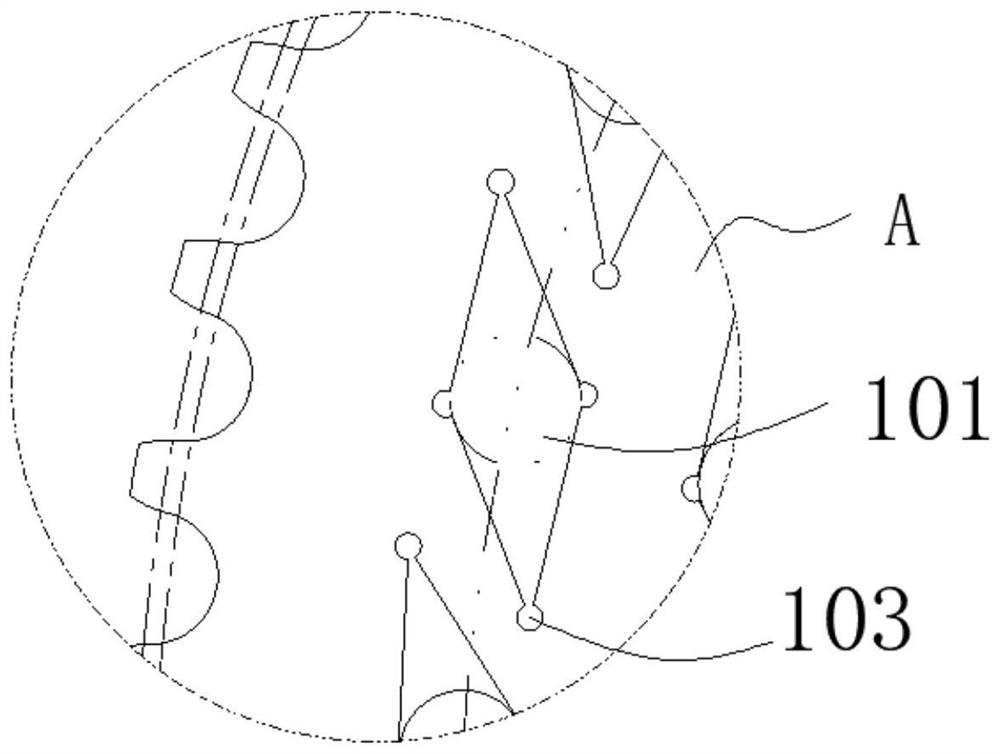

Planetary plate clamp, technology for machining rhombic blade through planetary plate clamp and rhombic blade

A planetary disc and fixture technology, which is applied in the direction of manufacturing tools, grinding workpiece supports, and other manufacturing equipment/tools, can solve the problems of uneven density distribution, large deformation of the bottom surface, and high scrap rate, so as to avoid rapid wear and tear. Larger, eliminates grinding errors, and improves service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

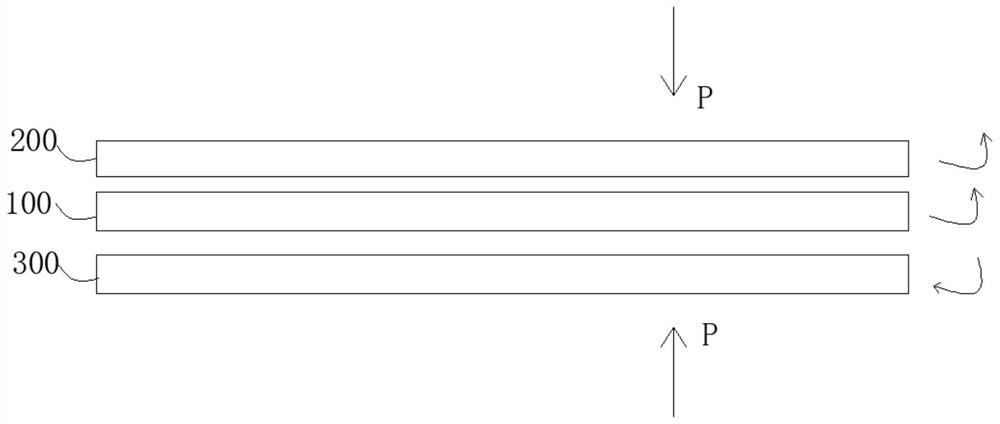

[0043] The above-mentioned processing technology is used, the difference is that the pressure is 5 pressure sections, and the specific P0 is 90N pressure and standing for 4s;

[0044] P1 is under 226N pressure, the upper grinding disc rotates 45rpm forward, the planetary disc fixture rotates 30rpm forward, and the lower grinding disc reverses 45rpm, and the time is 5s;

[0045] P2 is under the pressure of 470N, the upper grinding disc rotates forward at 70rpm for 8s, the planetary disc fixture rotates forward at 40rpm for 5s, and the lower grinding disc reverses at 90rpm for 8s;

[0046] P3 is under the pressure of 780N, the upper grinding disc rotates forward at 80rpm for 8s, the planetary disc fixture rotates forward at 50rpm for 5s, and the lower grinding disc reverses at 110rpm for 8s;

[0047] P4 is under 320N pressure, the upper grinding disc rotates 30rpm forward, the planetary disc fixture rotates 25rpm forward, and the lower grinding disc reverses 30rpm, and the time ...

Embodiment 2

[0050] The above-mentioned processing technology is used, the difference is that the pressure is 5 pressure sections, and the specific P0 is 120N pressure and standing for 5s;

[0051] P1 is under 280N pressure, the upper grinding disc rotates 45rpm forward, the planetary disc fixture rotates 30rpm forward, and the lower grinding disc reverses 45rpm, and the time is 5s;

[0052] P2 is under the pressure of 490N, the upper grinding disc rotates forward at 70rpm for 8s, the planetary disc fixture rotates forward at 40rpm for 5s, and the lower grinding disc reverses at 90rpm for 8s;

[0053] P3 is under the pressure of 730N, the upper grinding disc rotates forward at 80rpm for 8s, the planetary disc fixture rotates forward at 50rpm for 5s, and the lower grinding disc reverses at 110rpm for 8s;

[0054] P4 is under the pressure of 250N, the upper grinding disc rotates 30rpm forward, the planetary disc fixture rotates 25rpm forward, and the lower grinding disc reverses 30rpm, and the...

Embodiment 3

[0057] The above processing technology is used, the difference is that the pressure is 5 pressure sections, and the specific P0 is 130N pressure and standing for 3s;

[0058] P1 is under 240N pressure, the upper grinding disc rotates 45rpm forward, the planetary disc fixture rotates 30rpm forward, the lower grinding disc reverses 45rpm, and the time is 5s;

[0059] P2 is under the pressure of 470N, the upper grinding disc rotates forward at 70rpm for 8s, the planetary disc fixture rotates forward at 40rpm for 5s, and the lower grinding disc reverses at 90rpm for 8s;

[0060] P3 is under the pressure of 790N, the upper grinding disc rotates forward at 80rpm for 8s, the planetary disc fixture rotates forward at 50rpm for 5s, and the lower grinding disc reverses at 110rpm for 8s;

[0061] P4 is under 340N pressure, the upper grinding disc rotates 30rpm forward, the planetary disc fixture rotates 25rpm forward, and the lower grinding disc reverses 30rpm, and the time is 5s;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com