Robot grinding system and grinding clamp thereof

A robot and fixture technology, applied in the field of grinding, can solve the problems of waiting for the assembly line to stop and affect the grinding efficiency, and achieve the effect of improving the replacement speed, improving efficiency and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

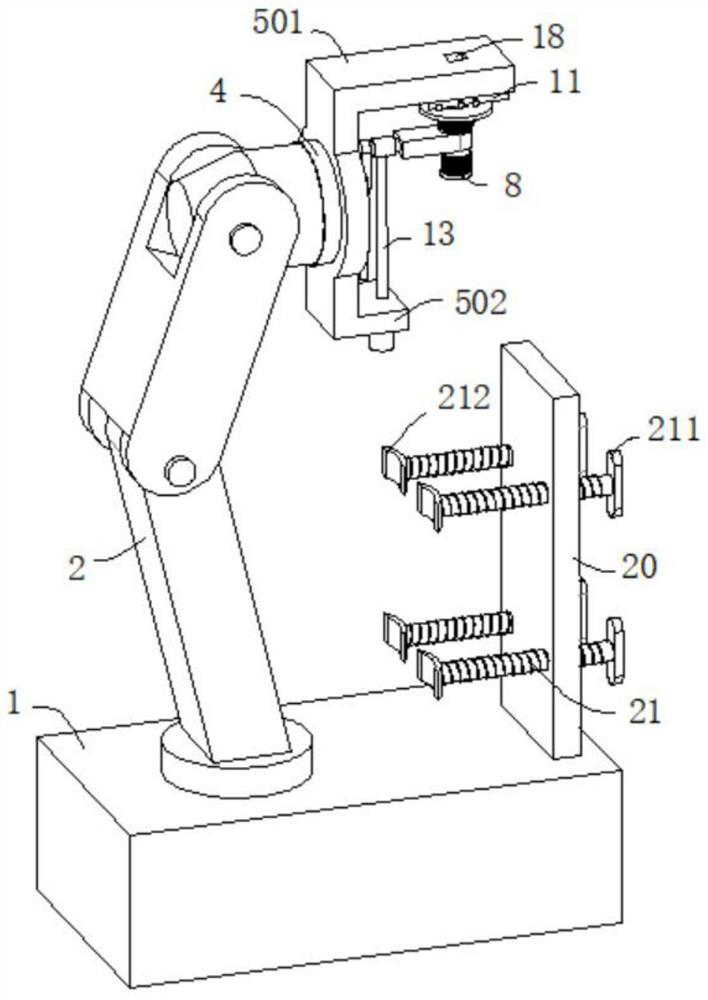

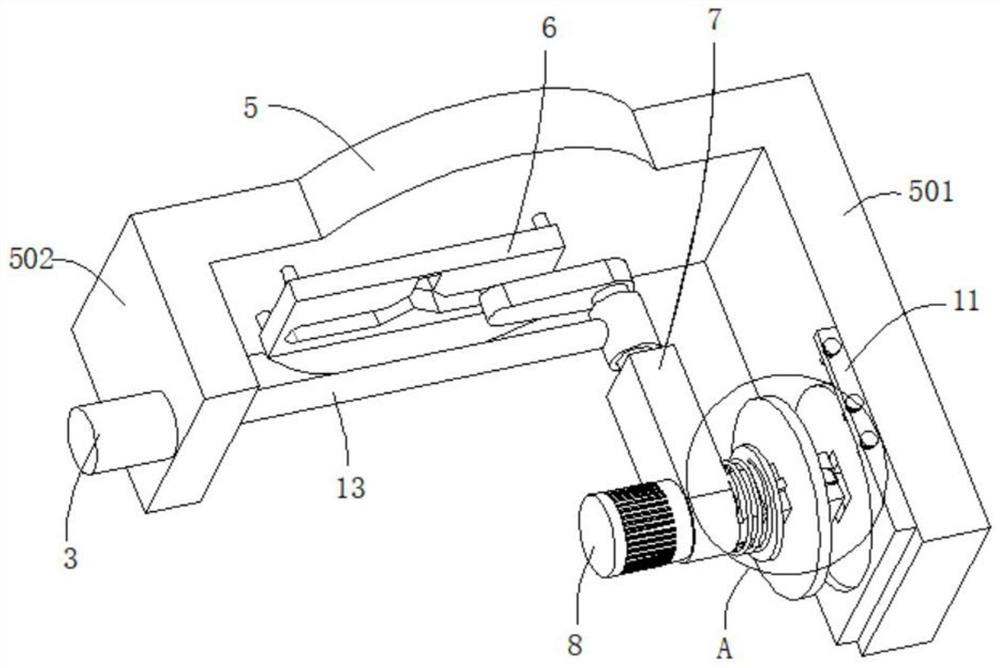

[0034] refer to Figure 1-7, a robot grinding system, comprising a grinding table 1, the top of the grinding table 1 is connected with a mechanical arm 2 and a grinding fixture, the end of the mechanical arm 2 away from the grinding table 1 is connected with a rotating plate 4, and the outer wall of the rotating plate 4 is connected with a working plate 5 The two sides of the outer wall of the working plate 5 are respectively connected with the first side plate 501 and the second side plate 502, the outer wall of the working plate 5 is connected with the stroke plate 6 through the connecting rod, the outer wall of the stroke plate 6 is dug with a track groove 601, and the inner wall of the track groove 601 A moving rod 602 is movably connected, the outer wall of the moving rod 602 is connected with a connecting plate 603, the outer wall of the connecting plate 603 is connected with a fixed rod 604, and the end of the fixed rod 604 away from the connecting plate 603 is connected...

Embodiment 2

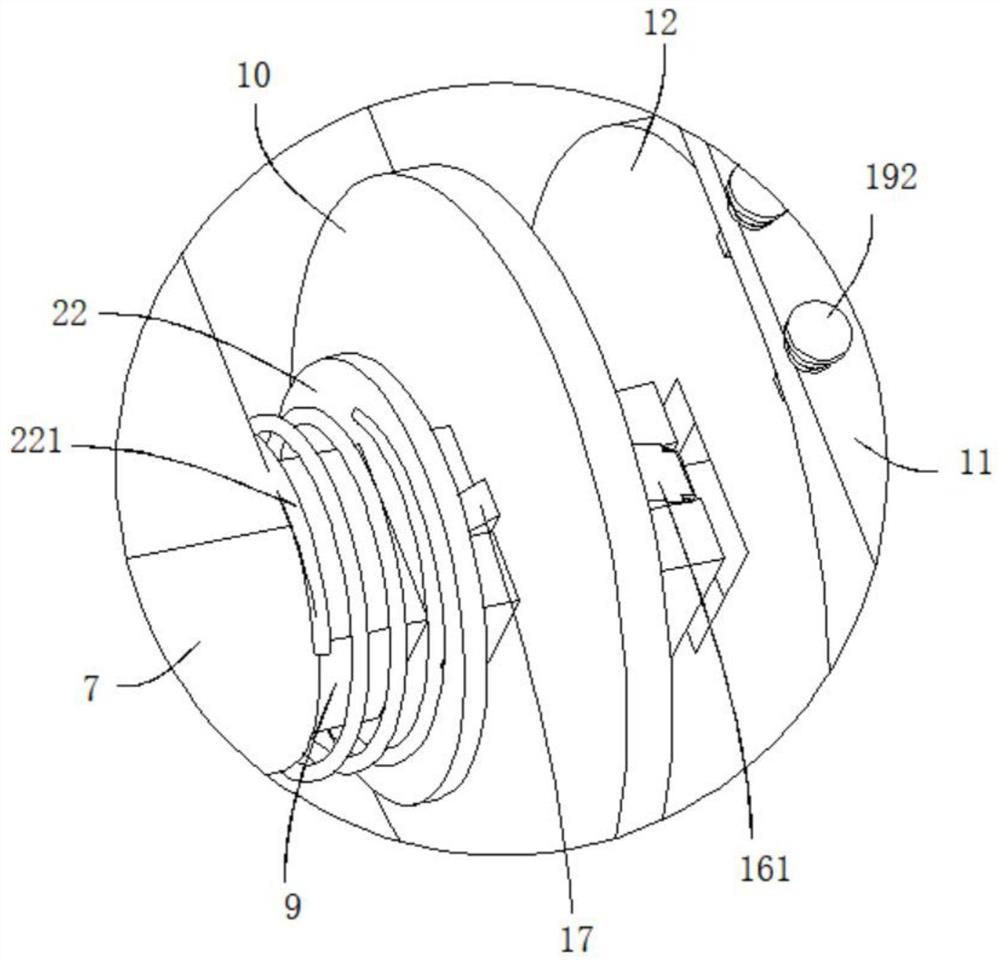

[0044] refer to image 3 , Figure 6 and Figure 8 , a robot grinding system, which is basically the same as that of Embodiment 1, furthermore, the outer wall of the rotating seat 9 is slidably connected with a baffle plate 22, and the outer wall of the rotating seat 9 is sleeved with a third elastic element 221, and the two ends of the third elastic element 221 The ends are respectively connected with the fixed seat 7 and the baffle plate 22; the working grinding wheel 10 is squeezed by the spare grinding wheel 12, so that the working grinding wheel 10 is placed between the block 17 and the baffle plate 22, and the working grinding wheel 10 is limited to avoid waste of work. The emery wheel 10 shakes when grinding the workpiece, causing the equipment to vibrate and affecting the grinding effect.

[0045] Placement frame 11 both sides outer walls are all excavated with chute 19, and chute 19 inwalls are slidably connected with slide bar 191, and the outer wall of slide bar 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com