Glass double-sided automatic polishing device

An automatic polishing and double-sided technology, which is applied in the direction of grinding drive device, grinding/polishing equipment, grinding feed movement, etc., can solve the problems of injury to master workers, complicated and inconvenient flipping glass products, and low polishing efficiency, etc., to achieve Simple and quick adjustment, improved polishing efficiency, efficient and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

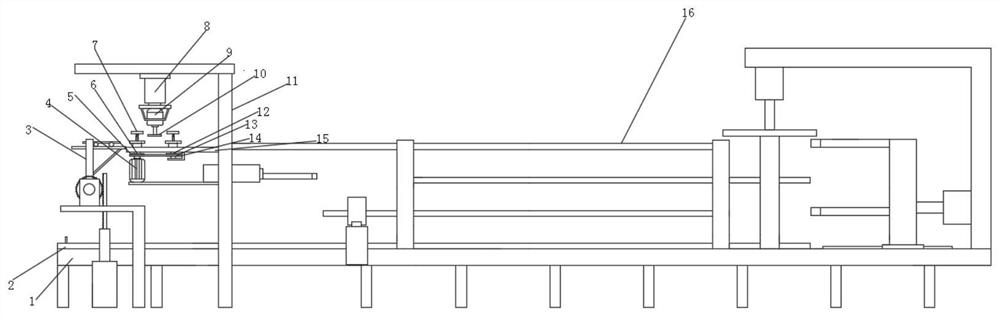

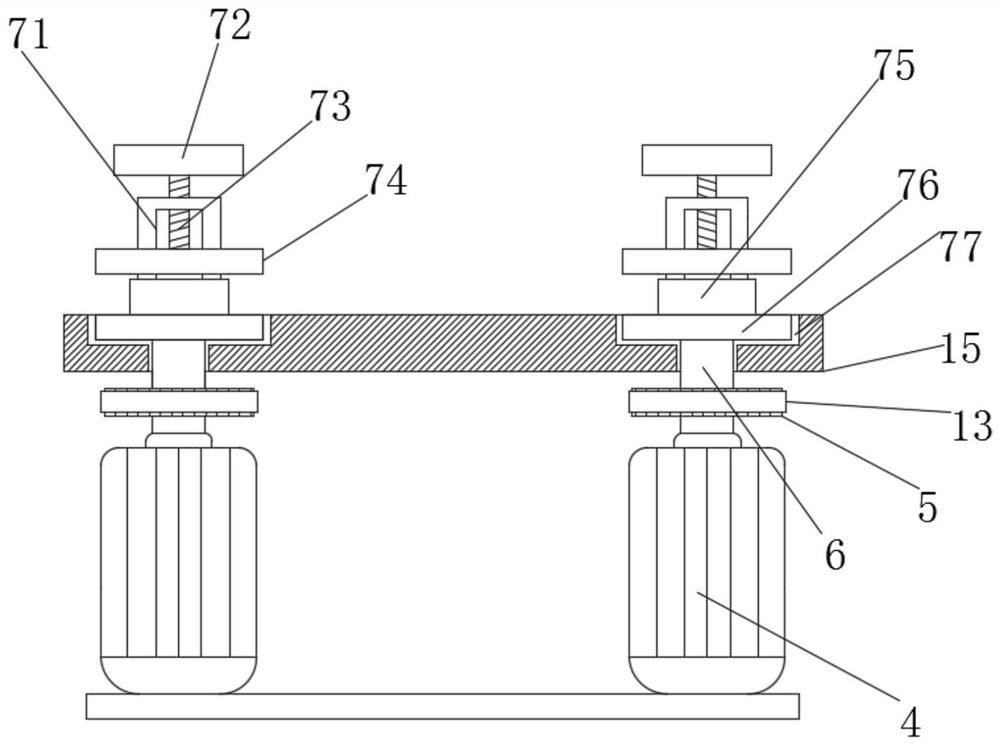

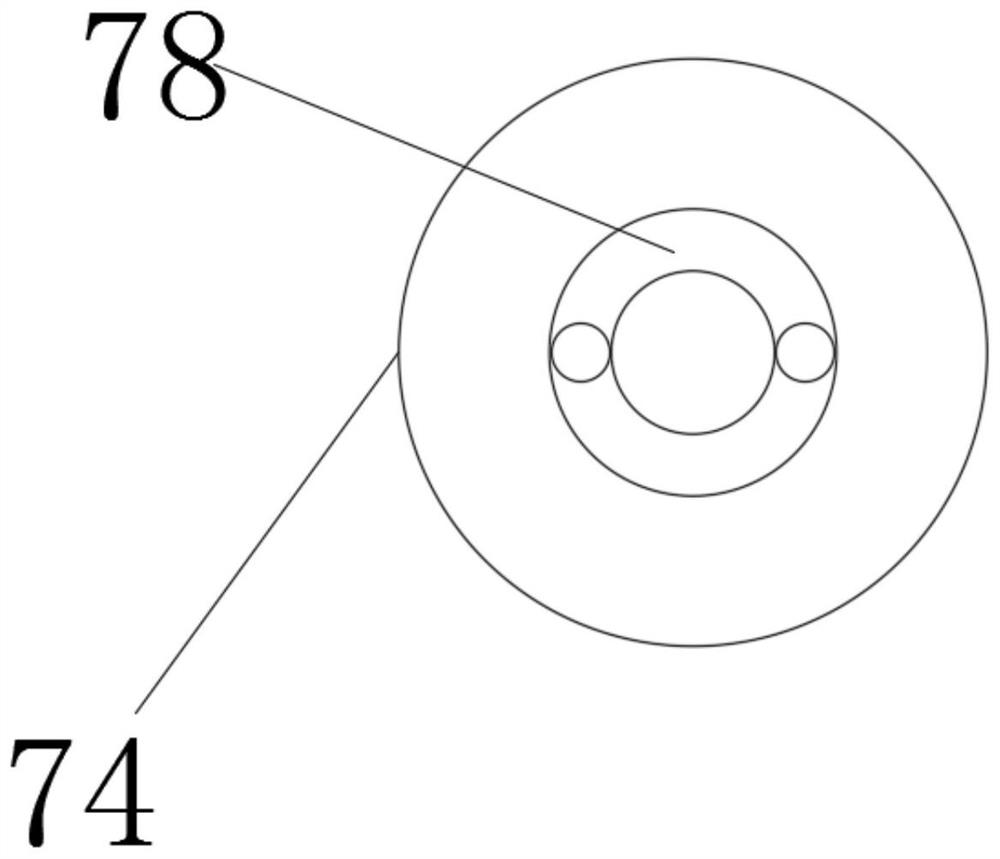

[0034]A glass double-sided automatic polishing device, including a fixed table 15, a turning mechanism 3 and a transmission mechanism 16, a second support 11 is arranged above the fixed table 15, and a fourth cylinder 8 is arranged at the lower end of the second support 11. The lower end of the cylinder 8 is provided with a second motor 9, for the stability of the operation of the second motor 9, a receiving plate is provided between the second motor 9 and the fourth cylinder 8, and a frame is arranged outside the second motor 9, and the frame Fixed on the lower end of the receiving plate; the output end of the second motor 9 is provided with a polishing disc 10, the bottom of the fixed table 15 is provided with a first motor 4, the output end of the first motor 4 is provided with a first rotating shaft 6, and the first rotating shaft The surface of 6 is provided with first pulley 5, and the outside of first pulley 5 is provided with belt 13, and the inner side of the other end...

Embodiment 2

[0038] As an option, see figure 1 , Figure 4 , Figure 5 , Figure 6 , a glass double-sided automatic polishing device, the left side of the fixed table 15 is provided with a turning mechanism 3;

[0039] Turning mechanism 3 comprises the first cylinder 31 that is arranged on the ground, and the upper end of first cylinder 31 is provided with rack 32, and the left side of rack 32 is meshed with gear 34, and the middle outside of gear 34 is provided with rotating rod 312, rotates The two ends of bar 312 are provided with bearing seat 35, and bearing seat 35 is fixed on the first support 310, and first support 310 is fixed on the ground, is fixedly connected with two groups of turning bars 39 on the turning bar 312, and the two groups of turning bars 39 The inner side of the upper end is provided with a support plate 36, the upper surface of the support plate 36 is provided with a second cylinder 37, the output end of the second cylinder 37 is provided with a connecting bloc...

Embodiment 3

[0045] As an option, see figure 1 , Figure 7-10 , a glass double-sided automatic polishing device, the right side of the fixed table 15 is provided with a transmission mechanism 16;

[0046] The transmission mechanism 16 includes a first fixed rod 164 on the left side and a second fixed rod 1613 on the right side fixed on the upper end of the base 1, and three groups of second conveying racks 165 are erected between the first fixed rod 164 and the second fixed rod 1613 , the left side of the second conveyor frame 165 on the highest level is provided with a discharge conveyor frame 1614, the discharge conveyor frame 1614 is arranged on the right side of the fixed platform 15, and is connected with the fixed platform 15, and the first conveyor frame 2 is arranged on the bottom layer of the second conveyor frame. Below the second conveying frame 165, the left side of the first fixed rod 164 is provided with a first placement frame 161, and the front and back sides of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com