A stainless steel pipe chamfering equipment and its processing technology

A stainless steel and steel pipe technology, applied in the field of steel pipe processing, can solve the problems of high labor intensity and manual feeding, and achieve the effect of reducing labor intensity, quickly clamping steel pipes, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

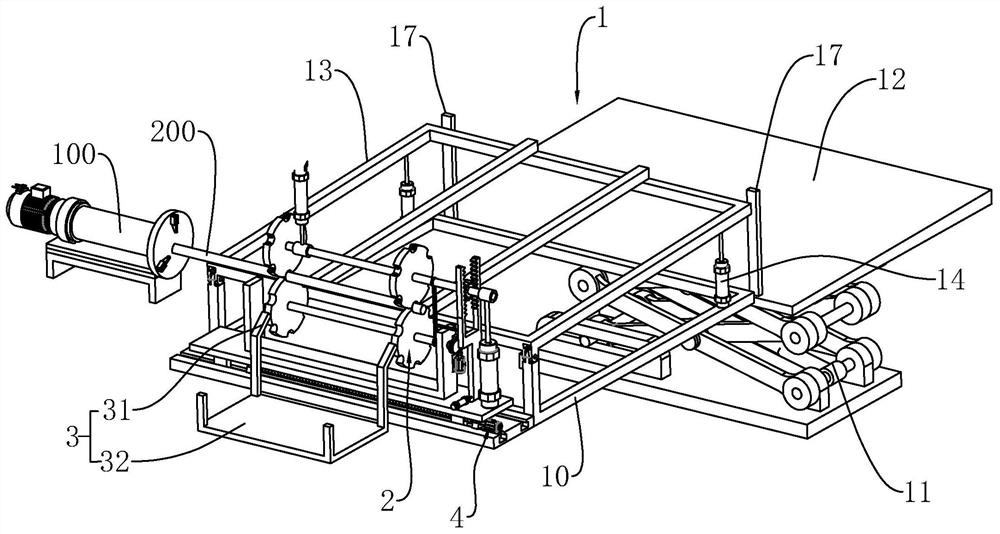

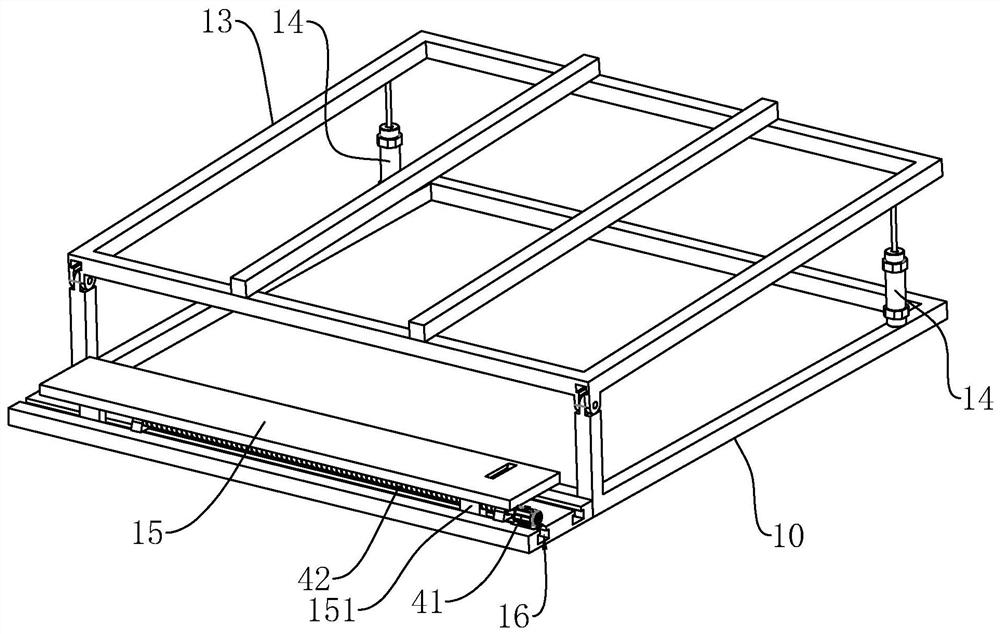

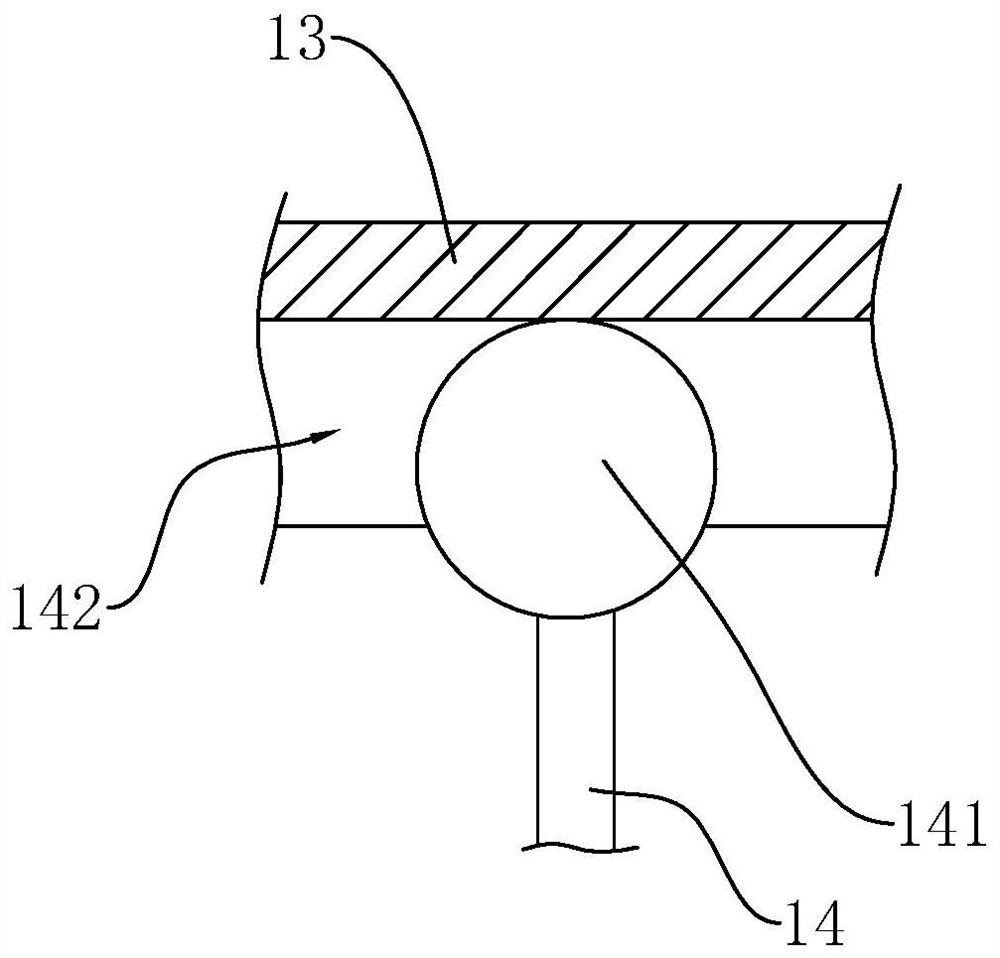

[0038] The following is attached Figure 1-5 The application is described in further detail.

[0039] The embodiment of the present application discloses a stainless steel pipe chamfering equipment. refer to figure 1 , including a chamfering machine body 100 and a frame 10 positioned at the feeding position of the chamfering machine body 100, wherein the frame 10 is provided with a feeding device 1 for conveying a feeding steel pipe 200, and is used to accept a feeding device 1 The steel pipe 200 is transferred to the transfer device 2 corresponding to the working position of the chamfering machine body 100, the receiving device 3 for collecting the chamfered steel pipe 200, and the frame 10 is also equipped with a drive transfer device 2 to approach or leave The linear drive assembly 4 of the chamfering machine body 100 .

[0040] Such as figure 1 , figure 2 As shown, the feeding device 1 includes a scissor lifting structure 11 installed below the ground, a lifting pall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com