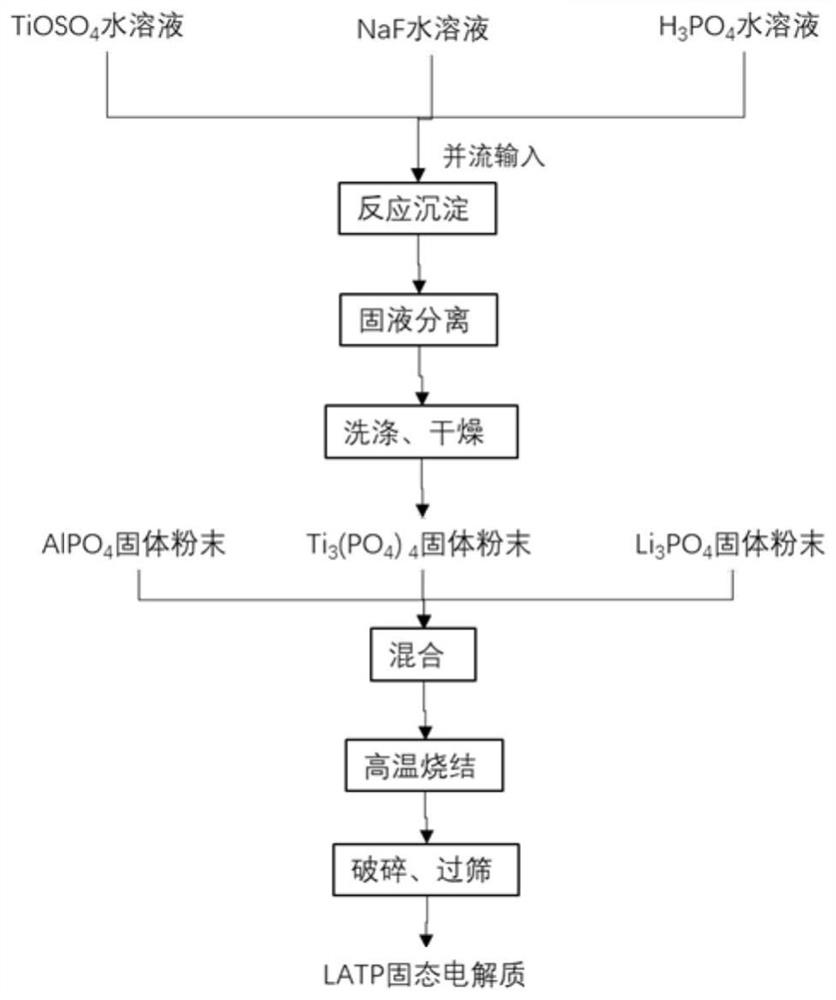

Preparation method of LATP solid electrolyte

A solid electrolyte and solid technology, applied in the field of preparation of LATP solid electrolyte, can solve the problems of many raw materials, large amount of waste gas, large difference in particle size of raw materials, etc., and achieve the effect of no impurity performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

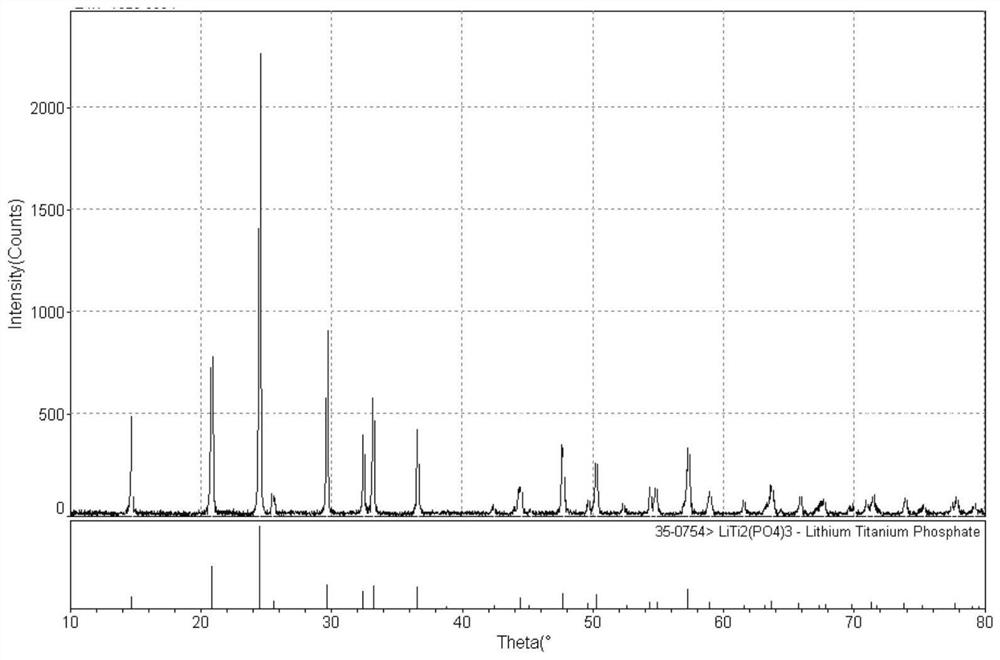

Embodiment 1

[0026] Weigh TiOSO 4 Dissolve 480g of solid particles in 2000g of deionized water, add an appropriate amount of sulfuric acid dropwise to adjust the pH of the solution to 1, stir and dissolve to obtain TiOSO with a concentration of 1.5mol / L 4 aqueous solution.

[0027] Weigh 21 g of NaF solid particles and dissolve in 1000 g of deionized water, stir and dissolve to obtain a NaF aqueous solution with a concentration of 0.5 mol / L.

[0028] Measure 274mL of 85% phosphoric acid solution and dissolve it in 1726g of deionized water, stir evenly to obtain H2O with a concentration of 2mol / L 3 PO 4 aqueous solution.

[0029] Add 1000 g of deionized water to the reactor, add an appropriate amount of sulfuric acid to adjust the pH of the solution to 1, add 10.5 g of NaF solid particles, start stirring and mix evenly, and heat the reactor to 50°C.

[0030] The prepared TiOSO 4 aqueous solution, NaF aqueous solution, H 3 PO 4 The aqueous solution is input into the reactor to react i...

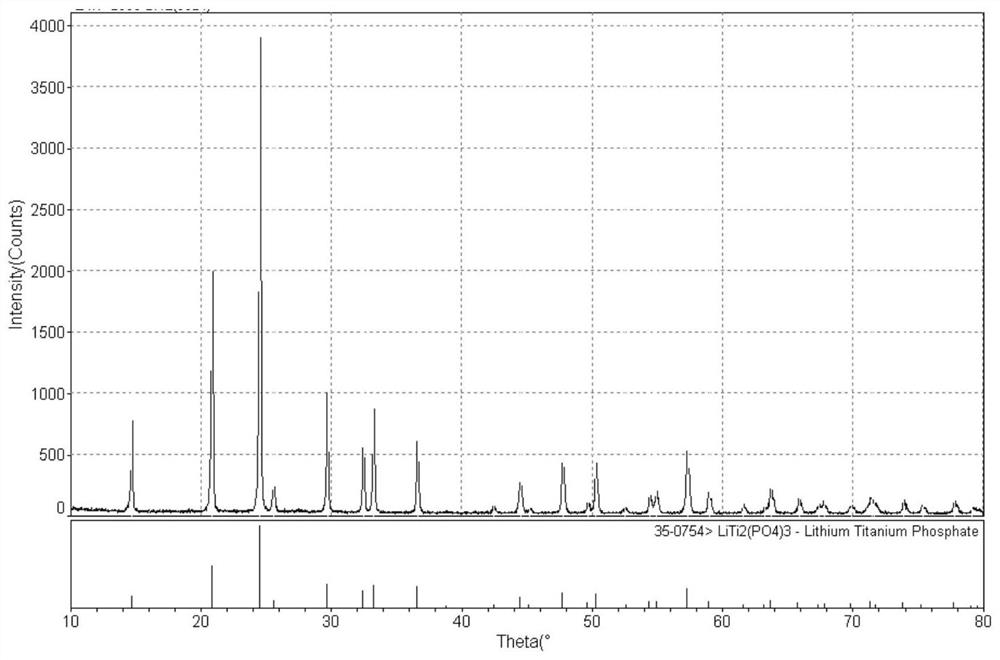

Embodiment 2

[0035] Weigh TiOSO 4 Dissolve 480g of solid particles in 2000g of deionized water, add an appropriate amount of sulfuric acid dropwise to adjust the pH of the solution to 1, stir and dissolve to obtain TiOSO with a concentration of 1.5mol / L 4 aqueous solution.

[0036] Weigh 21 g of NaF solid particles and dissolve in 1000 g of deionized water, stir and dissolve to obtain a NaF aqueous solution with a concentration of 0.5 mol / L.

[0037] Measure 274mL of 85% phosphoric acid solution and dissolve it in 1726g of deionized water, stir evenly to obtain H2O with a concentration of 2mol / L 3 PO 4 aqueous solution.

[0038] Add 1000g of deionized water to the reactor, add an appropriate amount of sulfuric acid to adjust the pH to 1, add 10.5g of NaF solid particles, start stirring and mixing evenly, and heat the reactor to 50°C.

[0039] The prepared TiOSO 4 aqueous solution, NaF aqueous solution, H 3 PO 4 The aqueous solution is input into the reactor to react in parallel, whe...

Embodiment 3

[0044] Weigh TiOSO 4 Dissolve 480g of solid particles in 2000g of deionized water, add an appropriate amount of sulfuric acid dropwise to adjust the pH of the solution to 1, stir and dissolve to obtain TiOSO with a concentration of 1.5mol / L 4 aqueous solution.

[0045] Weigh 21 g of NaF solid particles and dissolve in 1000 g of deionized water, stir and dissolve to obtain a NaF aqueous solution with a concentration of 0.5 mol / L.

[0046] Measure 274mL of 85% phosphoric acid solution and dissolve it in 1726g of deionized water, stir evenly to obtain H2O with a concentration of 2mol / L 3 PO 4 aqueous solution.

[0047] Add 1000g of deionized water to the reactor, add an appropriate amount of sulfuric acid to adjust the pH to 1, add 10.5g of NaF solid particles, start stirring and mixing evenly, and heat the reactor to 50°C.

[0048] The prepared TiOSO 4 aqueous solution, NaF aqueous solution, H 3 PO 4 The aqueous solution is input into the reactor to react in parallel, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com