Fabricated environment-friendly building wall body and construction method thereof

A building wall and assembly technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of low installation accuracy, achieve the effect of improving the load bearing capacity, improving installation accuracy, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

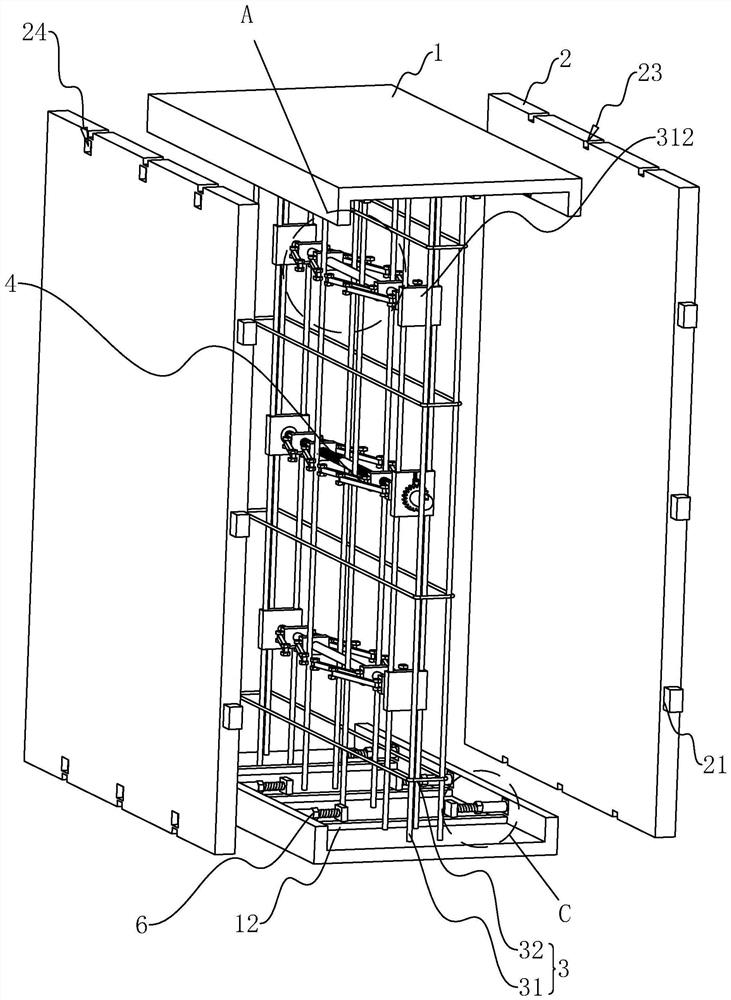

[0044] The following is attached Figure 1-8 The application is described in further detail.

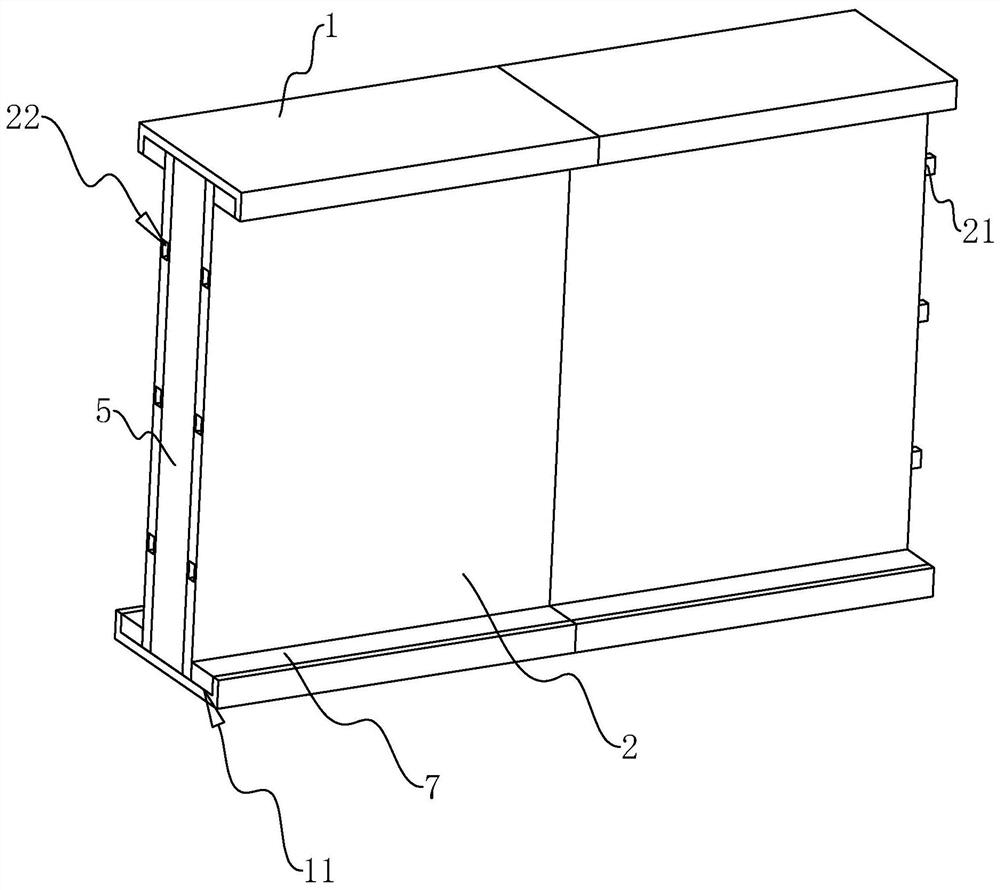

[0045] The embodiment of the present application discloses a prefabricated environmental protection building wall. refer to figure 1 The wall of the prefabricated environment-friendly building includes a plurality of wall units, and adjacent wall units are spliced together.

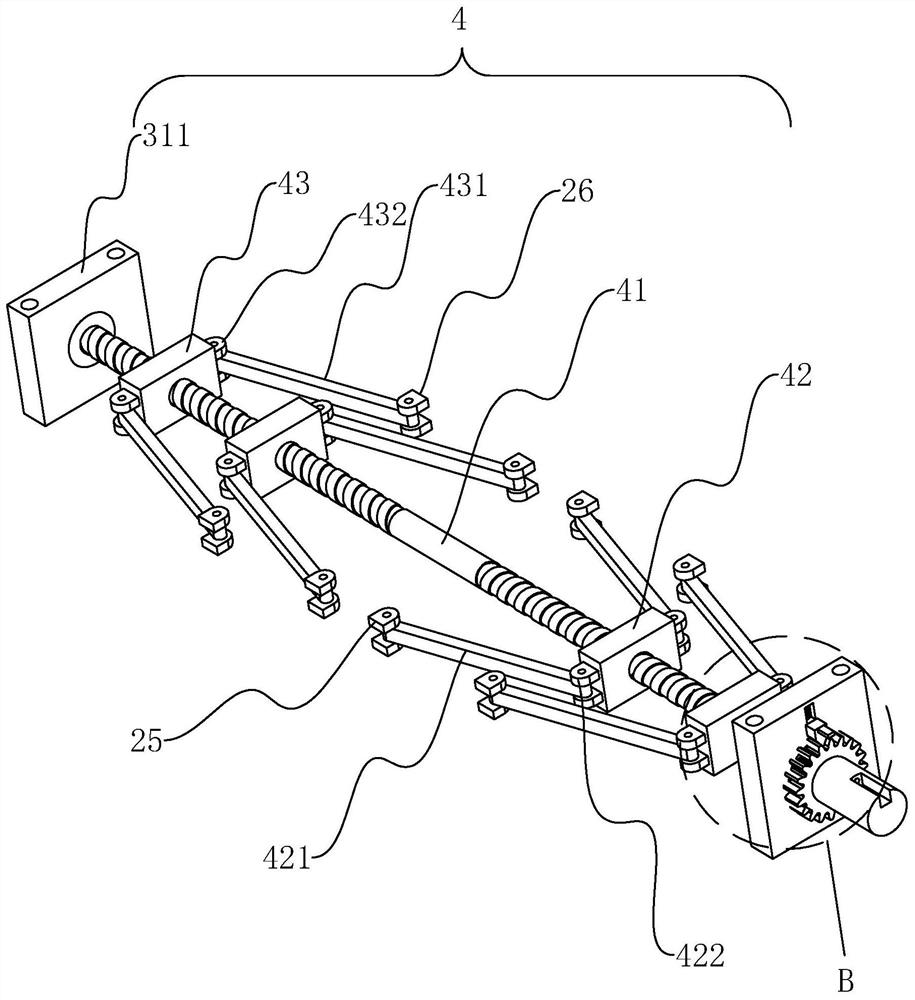

[0046] refer to figure 1 and figure 2 , the wall unit includes two oppositely arranged bases 1 and two oppositely arranged wall panels 2, the base 1 is in the shape of a cuboid and arranged horizontally, the wall panels 2 are in the shape of a cuboid and arranged vertically, and the length of the base 1 is equal to that of the wall panels 2 width dimensions. The side wall of the wallboard 2 is fixed with a plurality of plug-in blocks 21, and the side wall of the wallboard 2 away from the plug-in blocks 21 is provided with a plug-in groove 22 that is plugged and adapted to the plug-in blocks 21. The conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com