Pin abutting seat for surgical staple

A technology of needle holder and stapler, which is applied in the field of medical devices, can solve problems such as shaking, poor strength, and inability to realize titanium nail forming, so as to achieve good suture effect and avoid irregular movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

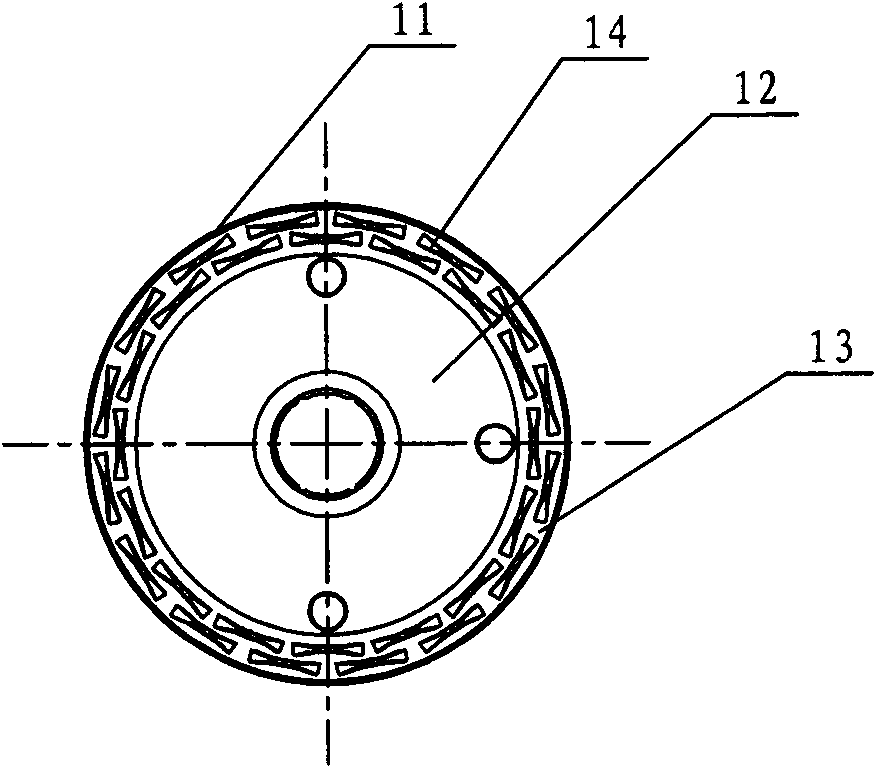

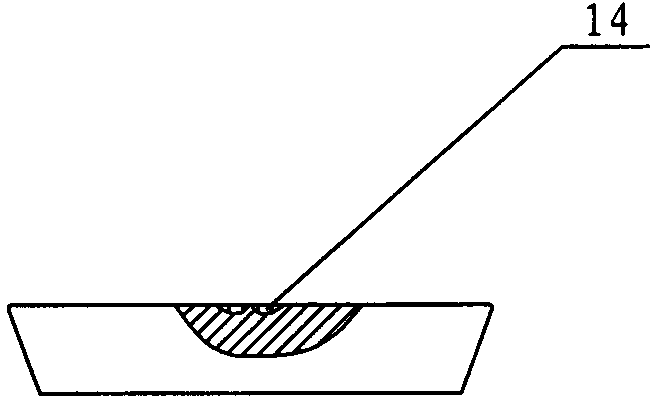

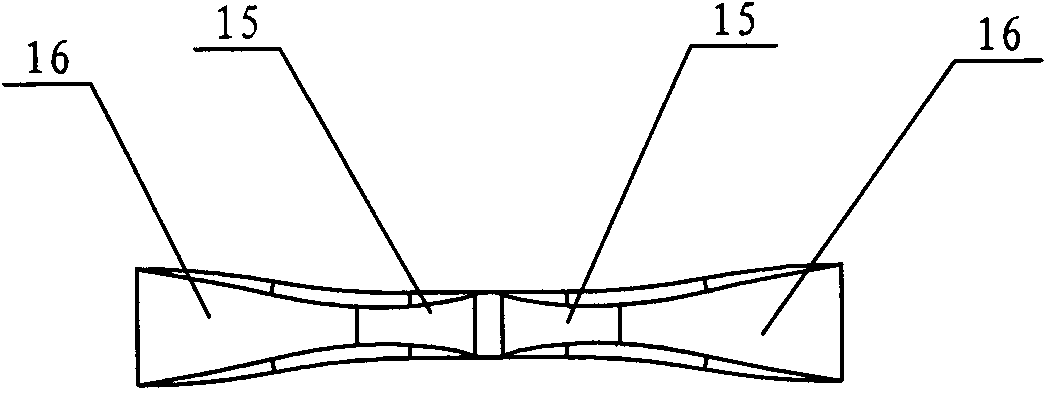

[0022] like Figure 1-2 As shown, an abutment seat for an anastomat includes a cylindrical trapezoidal seat body 11, and one end of the seat body 11 opposite to the end of the needle seat cap is provided with a counterbore 12 inwardly, and a ring surface 13 is formed on the end surface. The head of 11 is connected with the needle seat cap in the stapler, and one end of the seat body 11 opposite to the needle seat cap is provided with several nail grooves 14, two nail grooves 14 form a group, and the nail grooves 14 rotate around the seat body 11 The shafts are arranged in an array of inner and outer rings, and each group of nail grooves 14 on the inner and outer rings is distributed across, and the distance between the nail grooves 14 on the inner ring and the inner diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com