Drainage pipeline detecting and cleaning robot

A technology for drainage pipes and robots, which is applied in the direction of cleaning sewer pipes, waterway systems, water supply devices, etc., can solve the problems of difficult rollers, easy slippage of pipeline robot rollers, out of control, and travel obstacles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

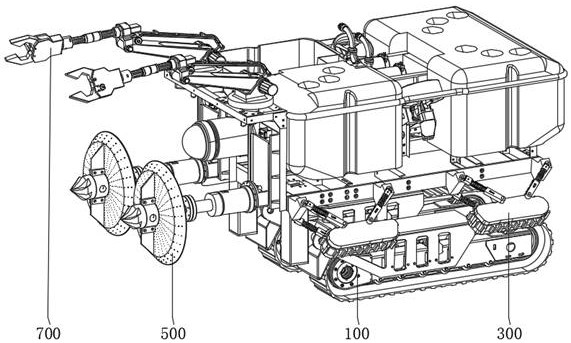

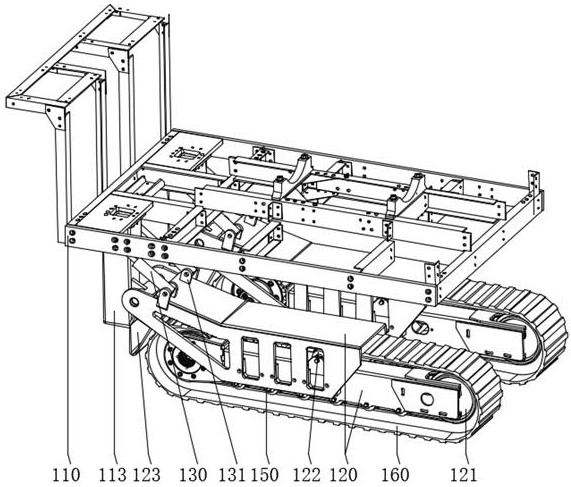

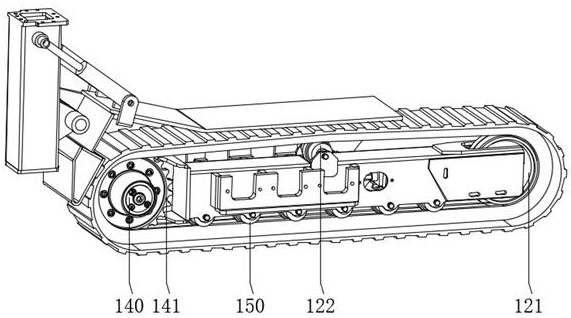

[0042] like Figure 1-Figure 7 As shown, the drainage pipe inspection and cleaning robot according to the embodiment of the present application includes a climbing assembly 100, a balancing assembly 300, a detection assembly 500, and a cleaning assembly 700. The balancing assembly 300 is installed on the climbing assembly 100, and the detection assembly 500 is installed on the On one side of the climbing assembly 100, the cleaning assembly 700 is installed on the other side of the climbing assembly 100. The climbing assembly 100 uses crawlers to travel to overcome various pipeline obstacles, increase the friction and support area of the robot, and improve the stability and balance of the device. Component 300 is hydraulically propelled by a propeller to facilitate the robot to quickly get rid of the sludge, overcome the impact of pipeline water flow, and maintain balance and stability. The detection component 500 is accurately placed in the water source of the detection point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com