Aluminum alloy plate vacuum electron beam welding method, flange and X-ray image intensifier

A technology of vacuum electron beam and aluminum alloy plate, which is applied in the direction of electron beam welding equipment, welding equipment, welding/welding/cutting items, etc. It can solve the problems of poor sealing of welded joints, difficulty in meeting design requirements, and many pores inside welds, etc. , to achieve the effect of less pores inside the weld, long service life and small spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

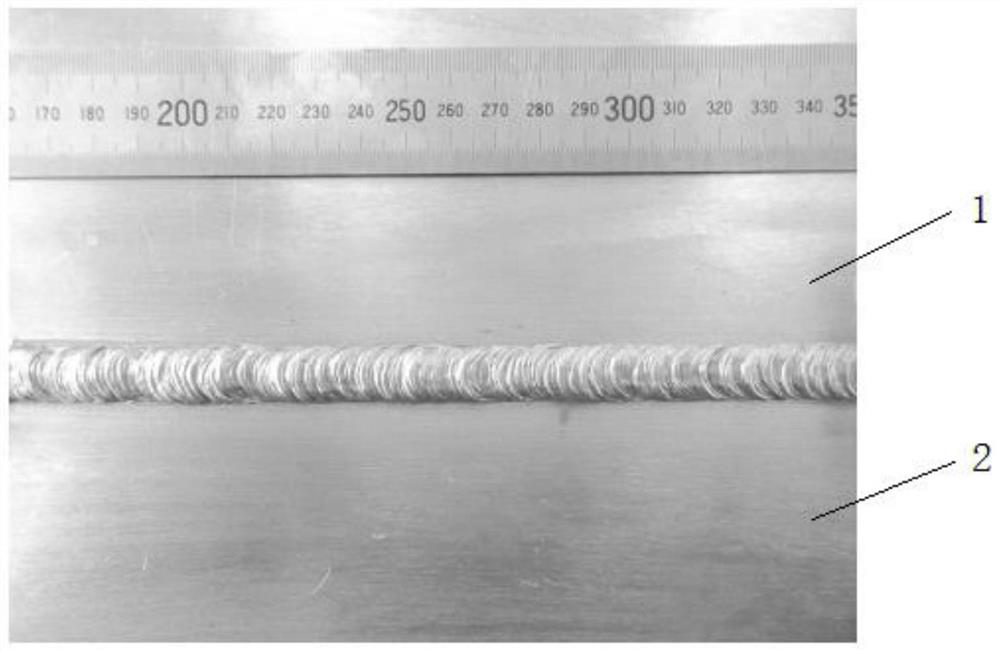

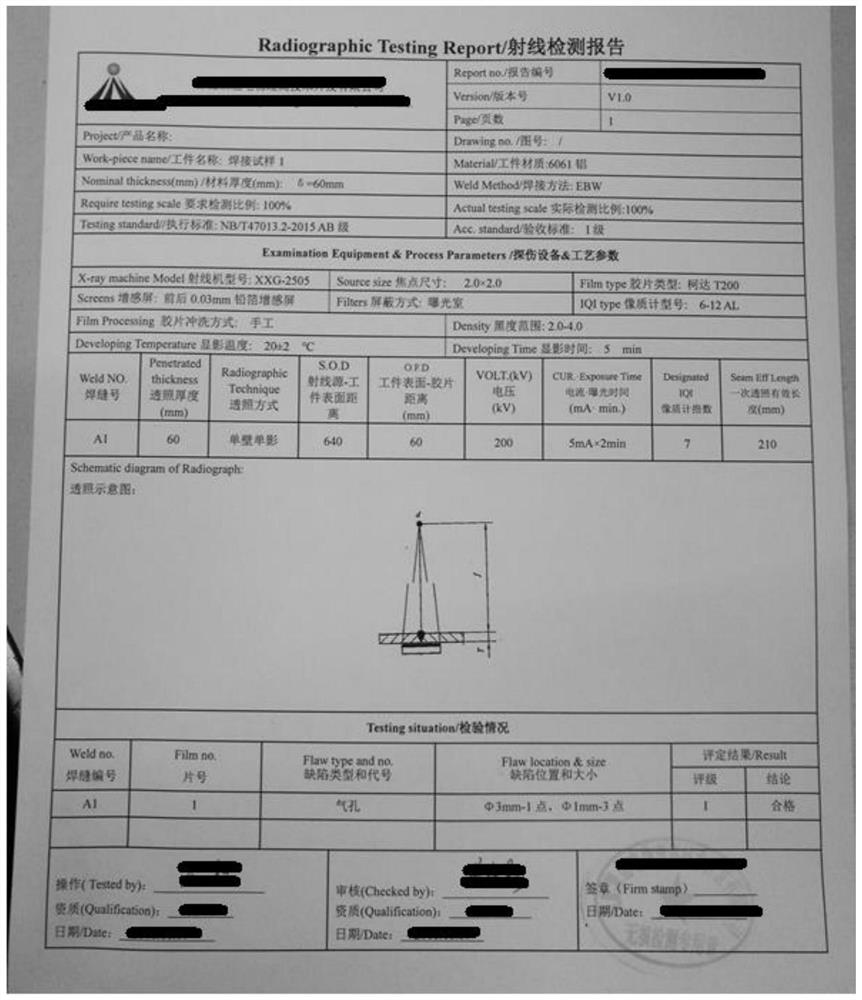

[0024] This embodiment takes vacuum electron beam welding of two 6061 aluminum alloy plates (hereinafter referred to as aluminum alloy plates) as an example, including the first aluminum alloy plate 1 and the second aluminum alloy plate 2 (such as figure 1 shown), heat treatment state T6, plate thickness 60mm, length 300mm, width 150mm;

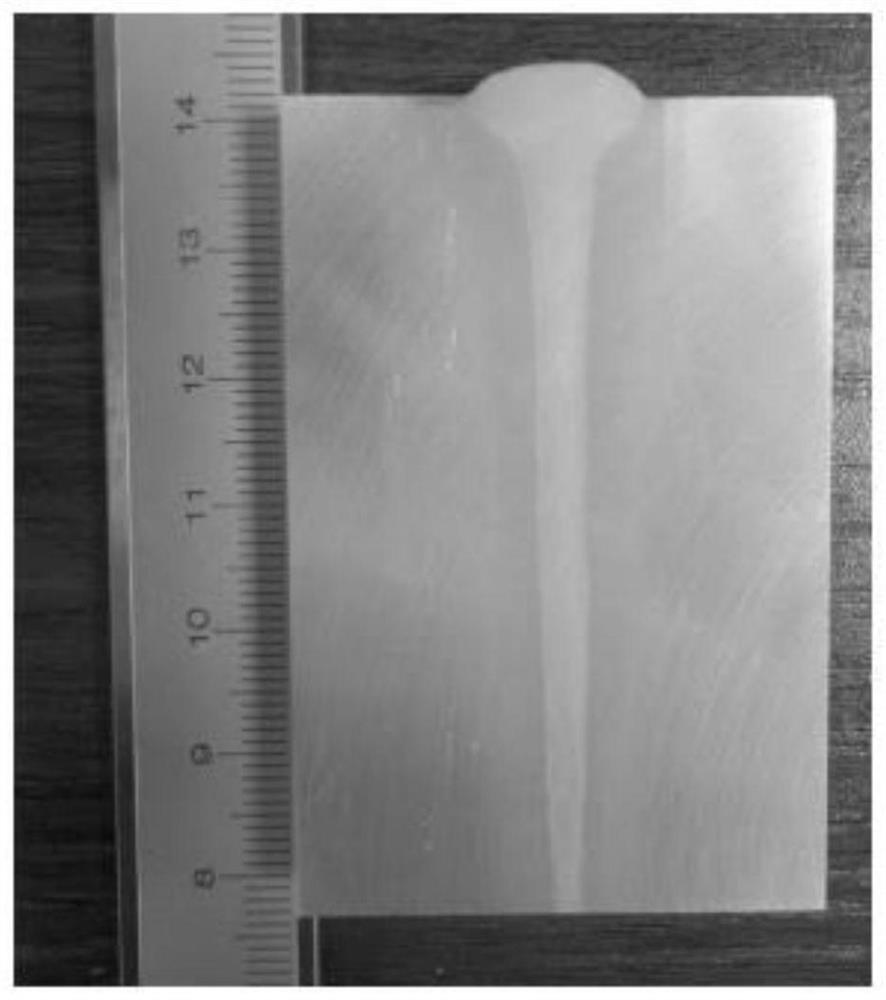

[0025] The welding requirements are: two aluminum alloy plates are butted along the width direction of the plate, and welded along the length direction of the plate, and the weld penetration is required to be greater than 60mm;

[0026] The matching material is a backing plate (not shown in the figure), and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com