High current circuit

A high-current, circuit technology, applied in motor vehicle high-current circuits, start-stop-automatic circuits, and high-current resistance fields, can solve problems such as inappropriate applications for a large number of applications, complex manufacturing of high-current circuit boards, and ohmic losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

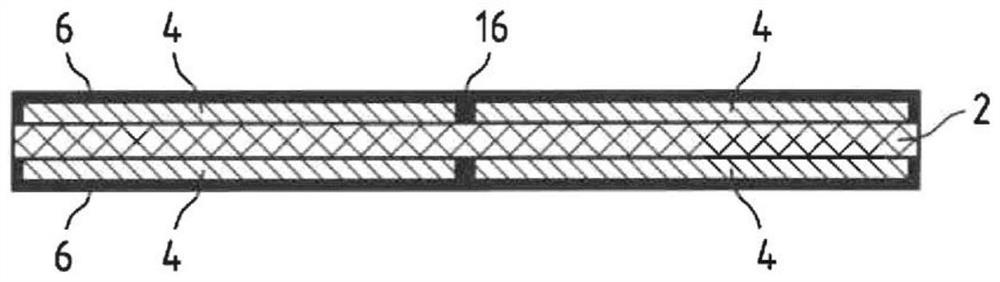

[0054] figure 1 A cross-section of a circuit board with a substrate 2 is shown. Substrate 2 may be fiber reinforced epoxy. Substrate 2 is in particular non-conductive. The substrate 2 is here a conventional substrate for circuit boards.

[0055] A conductor layer 4 is applied to the substrate 2 . The conductor layer 4 is in particular a copper layer. The conductor layer 4 is generally thinner than 1 mm and is brought into the desired topology by exposure and etching during the production of the printed circuit. Conductor layer 4 is covered by insulating layer 6 . The insulating layer 6 can be, for example, a solder resist varnish. At locations where the conductor layer 4 is to be contacted, the insulating layer 6 can be removed and / or the conductor layer 4 can be led out of the insulating layer 6 there. Thus, for example, contact pads can be applied to the conductor layer 4 . figure 1 The structure of the medium circuit board is conventional as it is used in standard c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com