Reductant spray device, exhaust gas processing device, and exhaust gas processing method

A technology of injection device and reducing agent, which is applied in the direction of electronic control, exhaust treatment, and noise reduction device of exhaust gas treatment device, can solve the problems of temperature reduction and uneven temperature of honeycomb structure, and achieve the effect of less power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0044] (1) Reductant injection device

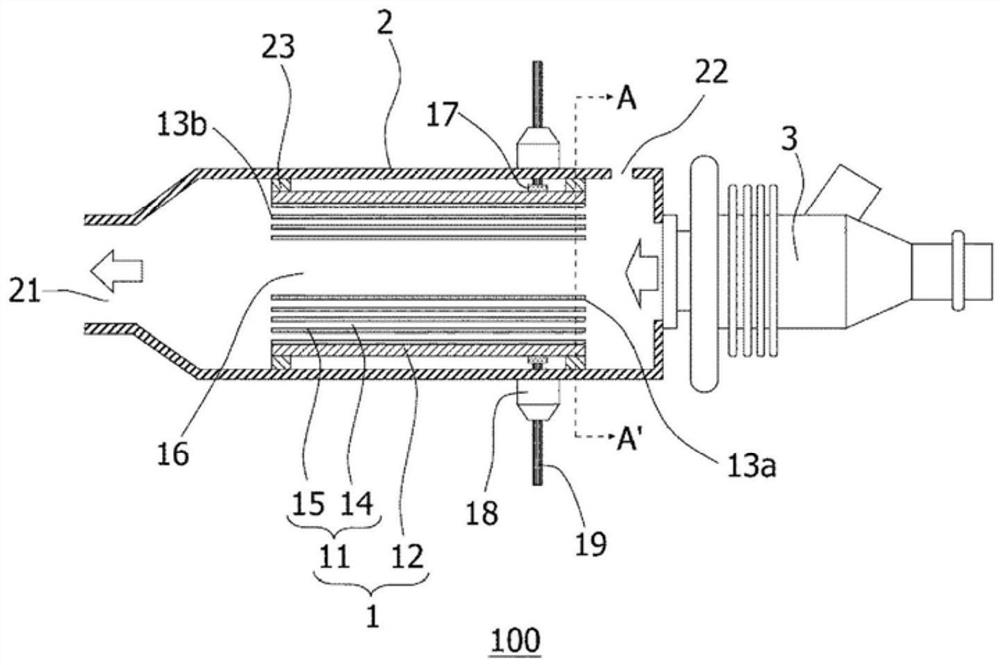

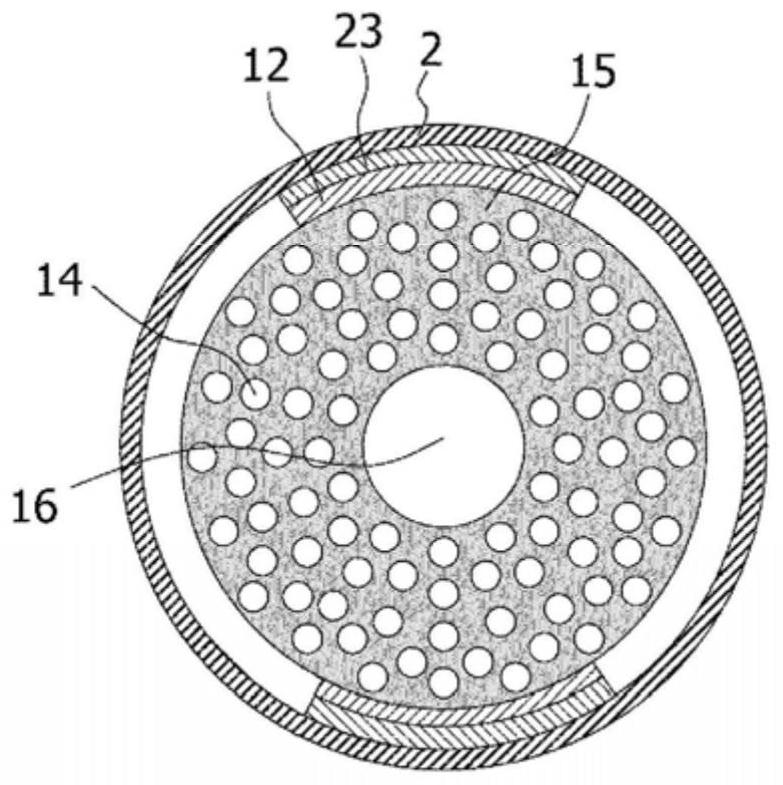

[0045] figure 1 It is a schematic sectional view showing the reducing agent injection device according to Embodiment 1 of the present invention (a schematic sectional view parallel to the direction in which the cells of the honeycomb structure portion extend). in addition, figure 2 yes figure 1 A schematic cross-sectional view of line AA' in (a schematic cross-sectional view perpendicular to the direction in which the cells of the honeycomb structure part extend).

[0046] Such as figure 1 and figure 2 As shown, the reducing agent injection device 100 of the present embodiment includes: a honeycomb structure 1 ; an outer cylinder 2 that accommodates the honeycomb structure 1 ; and a urea sprayer 3 disposed at one end of the outer cylinder 2 .

[0047] The honeycomb structure 1 has: a columnar honeycomb structure portion 11 having a partition wall 15 defining a plurality of compartments 14 extending from a fluid inflow end surface 13...

Embodiment approach 2

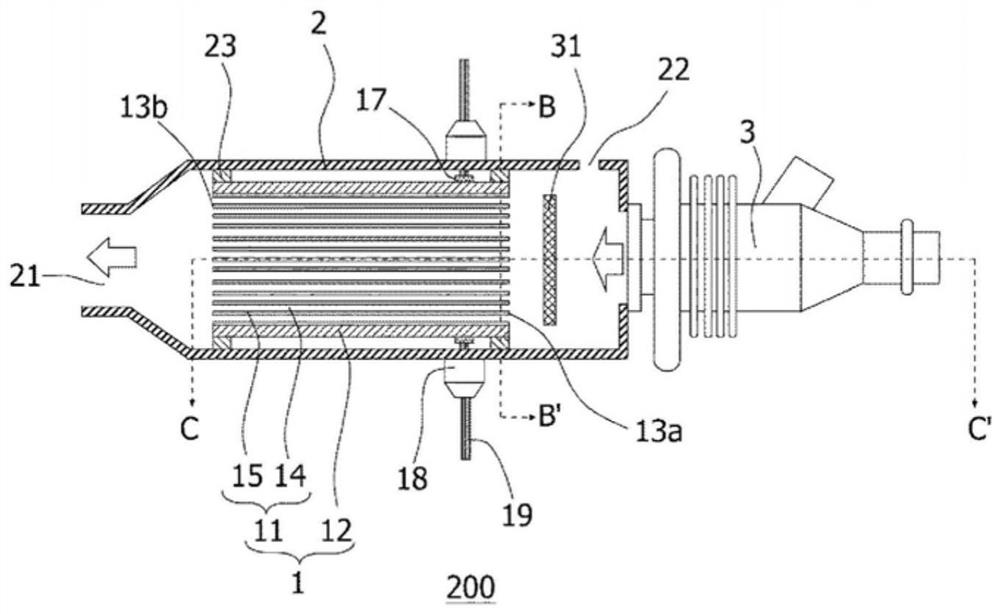

[0132] image 3 It is a schematic sectional view showing the reducing agent injection device according to Embodiment 2 of the present invention (a schematic sectional view parallel to the direction in which the cells of the honeycomb structure portion extend). in addition, Figure 4 yes image 3 A schematic cross-sectional view of the line BB' in (a schematic cross-sectional view perpendicular to the direction in which the cells of the honeycomb structure part extend), Figure 5 yes image 3 A schematic cross-sectional view of line CC' in (a schematic cross-sectional view parallel to the direction in which the cells of the honeycomb structure part extend).

[0133] Such as Figure 3 ~ Figure 5 As shown, in the reducing agent injection device 200 of the present embodiment, the honeycomb structure 1 having the quadrangular columnar honeycomb structure 11 is accommodated in the outer cylinder 2, and in the outer cylinder 2, the second flow path (the space region 16 ) is form...

Embodiment approach 3

[0138] Image 6 and Figure 7 It is a schematic cross-sectional view showing the exhaust gas treatment device according to Embodiment 3 of the present invention.

[0139] Such as Image 6 and Figure 7 As shown, the exhaust gas treatment devices 300 and 400 of this embodiment are equipped with: an exhaust cylinder 41, which is used for exhaust gas circulation; a reducing agent injection device 100, which injects ammonia or urea aqueous solution into the exhaust cylinder 41; and an SCR catalyst 42, which It is arranged on the downstream side of the exhaust pipe 41 from the position where the ammonia or urea aqueous solution is injected.

[0140]The exhaust pipe 41 is a pipe through which exhaust gas (exhaust gas containing NOx) discharged from various engines or the like flows, and the exhaust gas and ammonia are mixed therein. The size of the exhaust pipe 41 is not particularly limited, and may be appropriately determined according to an exhaust system of an engine or the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com