Roll and method for producing a roll

A technology of rollers and roller sleeves, applied in the field of manufacturing such rollers, can solve the problems of troublesome removal or removal of the roller sleeves, high cost, reduction of elastic modulus and hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

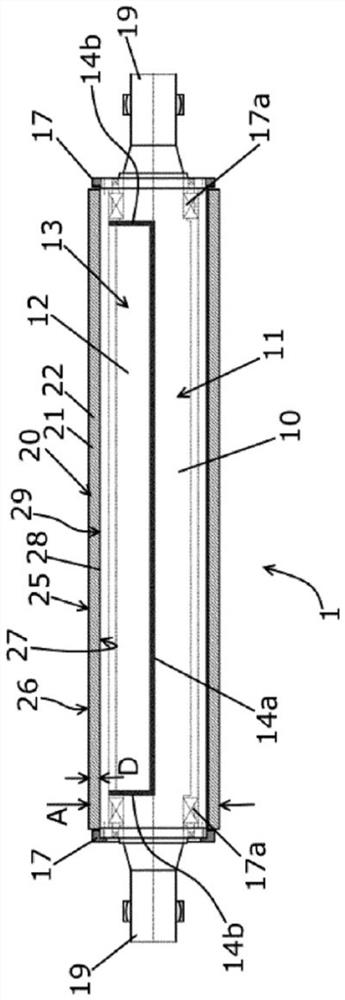

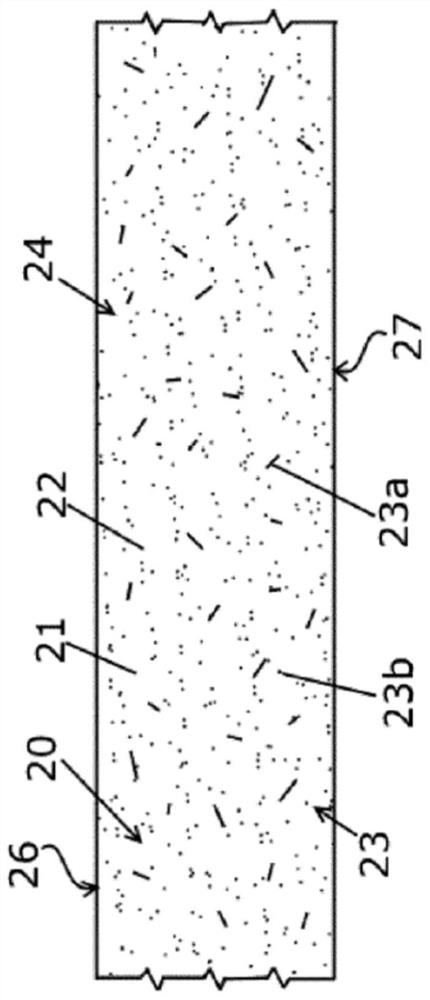

[0057] exist figure 1 A first embodiment of the roller 1 of the invention is shown in . The roll 1 is a processing roll and is currently constructed as a so-called bow compensation roll, in the form of a dancer roll. as in Figure 6 and 7 As exemplarily shown in , such a roller 1 is used, for example, in a device 30 for processing a nonwoven material web, a textile material web, a plastic product web or a paper product web to form a treatment with a paired roller 2 The processing gap 3 through which the web 4 is guided for processing. The roll 1 comprises in particular a roll frame 10 and a roll sleeve 20 rotatable about the roll frame 10 , in particular around a rotation axis extending in the longitudinal direction of the roll frame 10 .

[0058] At their axial ends, the roll stands 10 each have a roll neck 19 via which the roll stands 10 and finally the roll 1 can be supported on a non-illustrated fixed column or support. The whole formed by the roll stand 10 and the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus of elasticity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com