TBM operation parameter optimization method and system suitable for various rock mass conditions

A technology of operating parameters and optimization methods, applied in neural learning methods, design optimization/simulation, constraint-based CAD, etc., can solve problems such as difficulty in obtaining, lack of multiple constraints for different rock conditions, and optimization objectives of a single performance index, etc. Improve construction efficiency, save construction costs, and ensure the effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

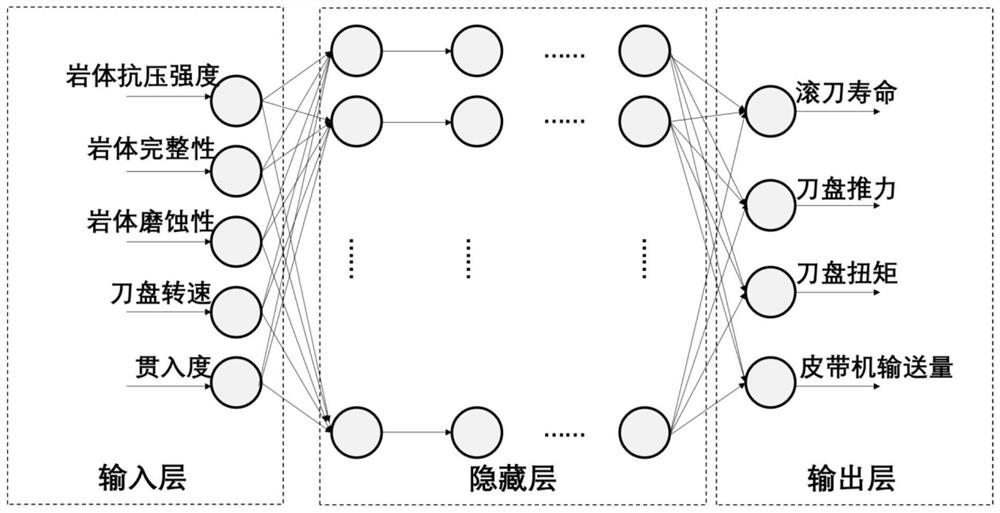

[0044] based on figure 1 , the TBM operating parameter optimization method applicable to various rock mass conditions of the present embodiment specifically includes the following steps:

[0045] Step S101: Obtain rock mass parameters and corresponding TBM excavation data, the TBM excavation data includes operating parameters and performance parameters.

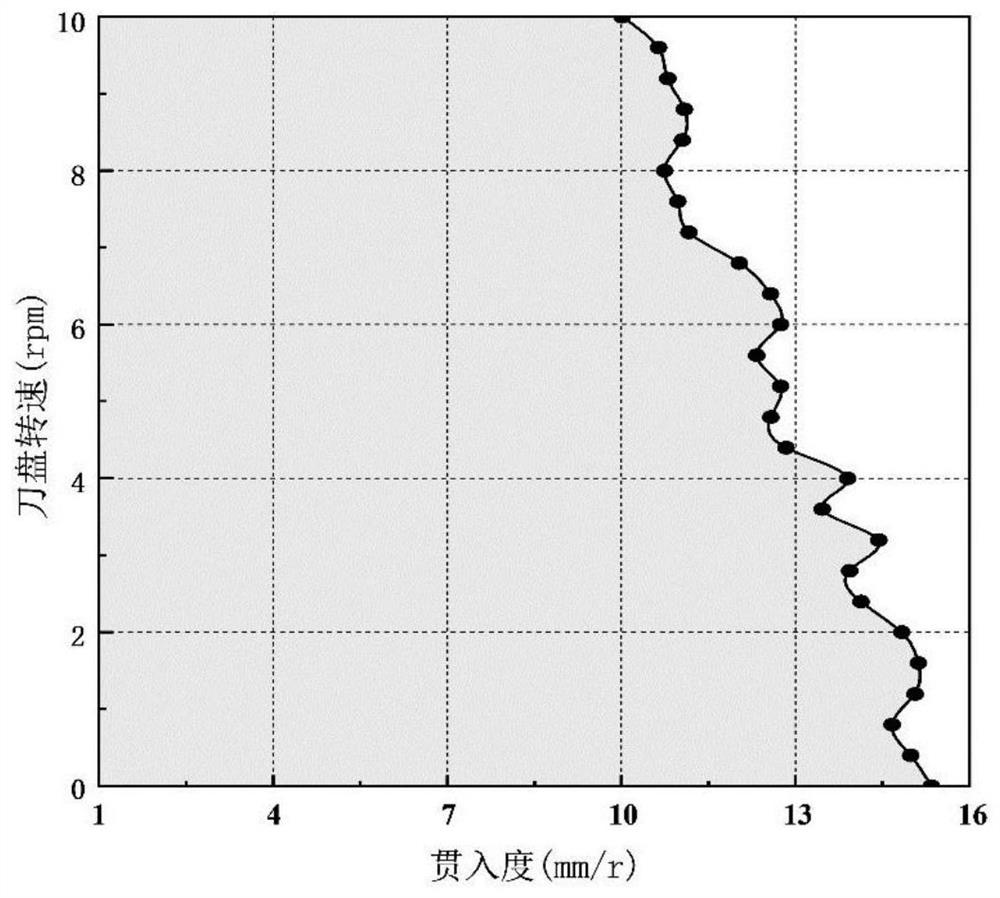

[0046] In a specific implementation, the operating parameters include, but are not limited to, the degree of penetration and the rotational speed of the cutter head.

[0047] Performance parameters include but are not limited to advance speed, reel life, thrust, torque and belt conveyor throughput.

[0048] Among them, the life of the hob is the ratio of the product of the square of the tunnel radius, the tunneling distance and π to the consumption of all the hobs.

[0049] Specifically, the original data of TBM operation and performance parameters such as cutterhead thrust, cutterhead torque, tunneling speed, and belt conv...

Embodiment 2

[0092] This embodiment provides a TBM operating parameter optimization system applicable to various rock mass conditions, which includes:

[0093] A data acquisition module, which is used to acquire rock mass parameters and corresponding TBM excavation data, the TBM excavation data including operating parameters and performance parameters;

[0094] The change law building module is used to take the rock mass compressive strength and penetration as input, and the cutterhead thrust as output to establish the first change law; take the rock mass compressive strength and penetration as input, and take the cutterhead thrust as Torque is the output, and the second change rule is established;

[0095] A dual-drive mapping relationship building module, which is used to take rock mass parameters and operating parameters as input, take the corresponding performance parameters as output, and use the first variation law and the second variation law as constraints to establish a dual-drive...

Embodiment 3

[0100] This embodiment provides a computer-readable storage medium, on which a computer program is stored. When the program is executed by a processor, the TBM operating parameter optimization method applicable to various rock mass conditions as described in the first embodiment above is implemented. A step of.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com