Method and system for measuring warping degree of liquid crystal substrate glass

A measurement method and liquid crystal substrate technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems that cannot completely eliminate the mechanical error of the 00-level marble platform surface of the liquid crystal substrate measuring device, and the unfavorable warping degree requirements, etc., to improve The effect of measurement efficiency and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

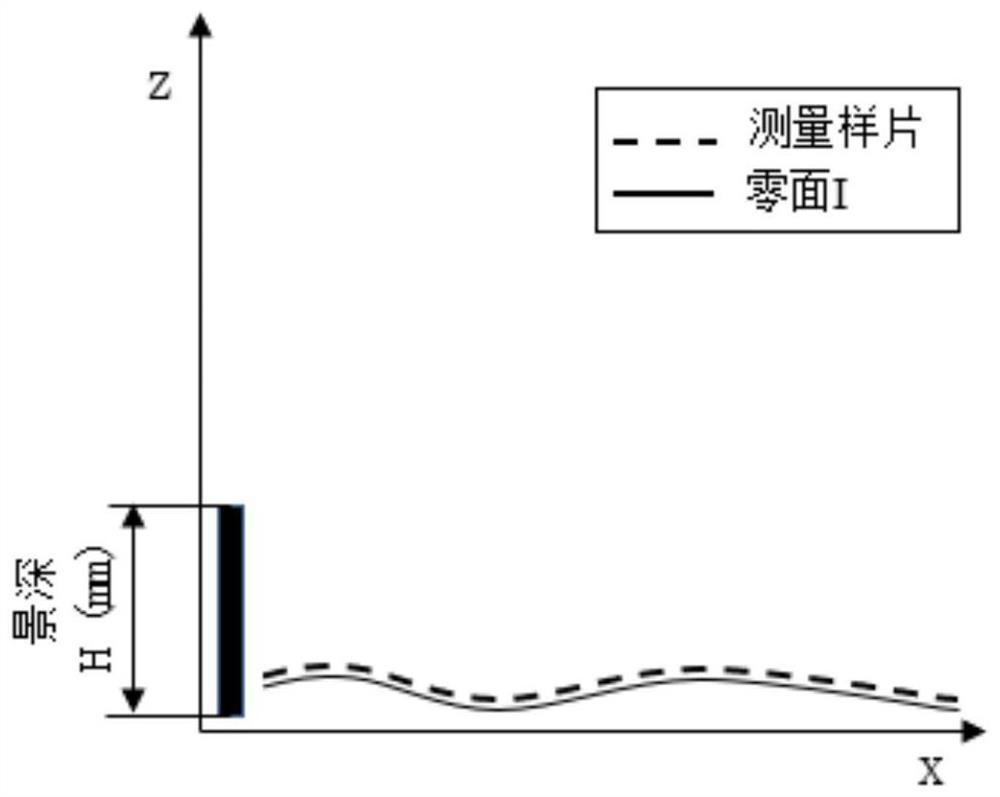

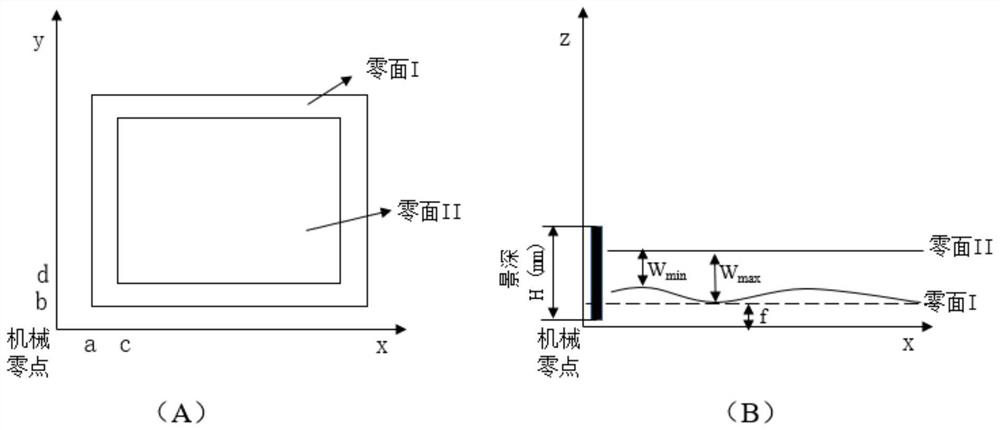

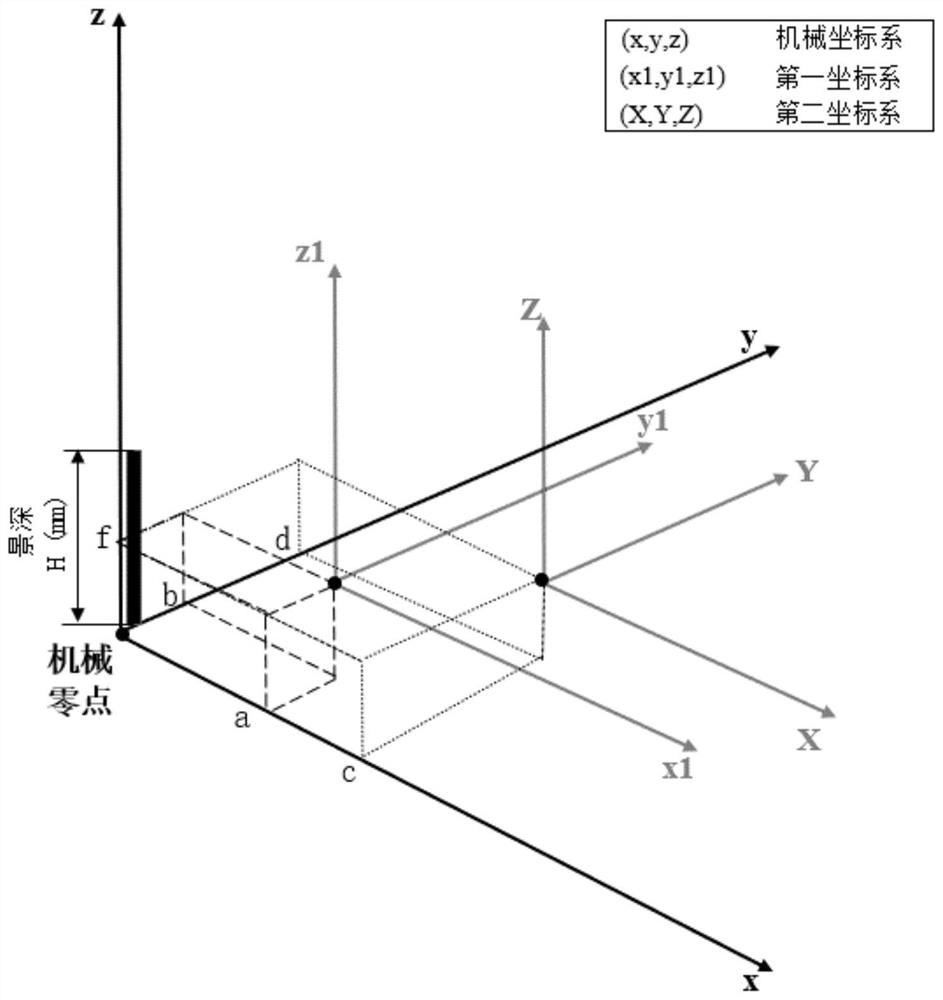

[0053] figure 1 It is a schematic diagram of the existing measurement system for measuring mechanical errors. Since the warpage value is the distance between the two points farthest from the tested sample plane in the height direction, if the tested sample is an absolute plane, the warped degree is 0. Such as figure 1 As shown, due to the mechanical error of the marble bearing platform, the surface is not an ideal horizontal two-dimensional plane. When measuring the warpage value of the glass sample of the liquid crystal substrate, the sample is placed on the marble bearing platform, and the sample is attached to the marble bearing platform. At this time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com