Graphene electric heat tracing structure for heat tracing of conveying pipeline

A transmission pipeline and graphene technology, applied in the direction of pipeline heating/cooling, pipe elements, heating elements, etc., can solve the problems of insufficient heat tracing uniformity, low heat tracing efficiency, uneven heat transfer, etc., and achieve low heat tracing efficiency , high heat tracing efficiency and fast thermal response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

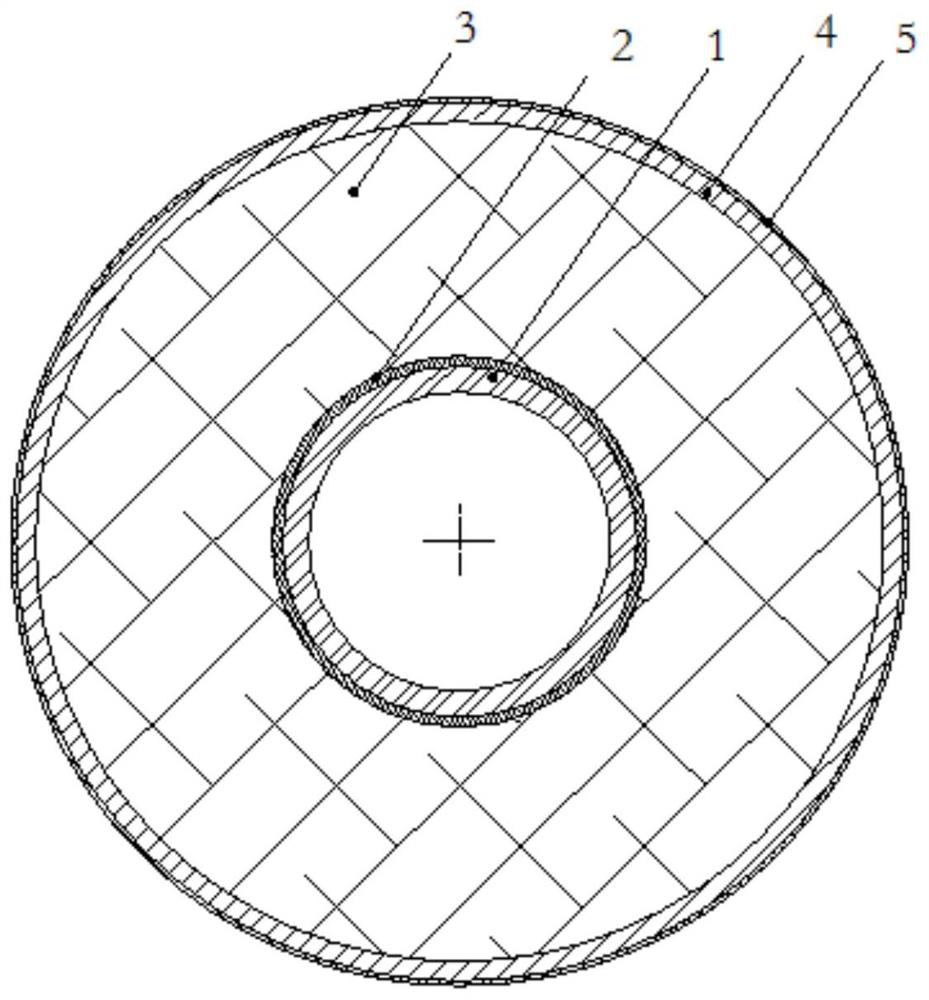

[0029] Such as figure 1 As shown, in this embodiment, a graphene electric heat tracing structure for heat tracing of the conveying pipeline is designed, including a graphene heating film 2, a heat insulating layer 3, a heat reflecting layer 4 and Protective sleeve 5; the graphene heating film 2 is closely attached to the delivery pipeline 1 and covers the outer peripheral wall of the delivery pipeline 1, and the graphene heating film 2 can be energized and heated to uniformly heat the delivery pipeline 1; the heat insulation layer and the heat The reflective layer is successively coated on the graphene heating film with cable ties; the protective sleeve 5 is a hard tube shell and is sleeved outside the heat reflective layer 4; the main function of the protective sleeve 5 is to prevent hail, stone Damage to the heat reflective layer 4 and heat insulation layer 3 by blocks, tramples or other impacts.

[0030]The pipe wall of the conveying pipeline 1 is made of heat-conducting m...

Embodiment 2

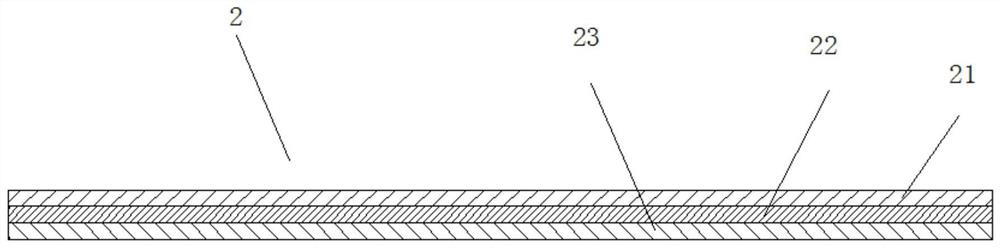

[0036] Such as Figure 1-2 As shown, in this embodiment, a graphene electric heat tracing structure for heat tracing of the transportation pipeline is designed, including a graphene heating film 2, a heat insulation layer 3, a heat reflection layer 4 and Protective sleeve 5; the graphene heating film 2 is closely attached to the delivery pipeline 1 and covers the outer peripheral wall of the delivery pipeline 1, and the graphene heating film 2 can be energized and heated to uniformly heat the delivery pipeline 1; the protective sleeve 5 is set outside the heat reflective layer 4 and completely covers the heat reflective layer 4.

[0037] The pipe wall of the conveying pipeline 1 is made of heat-conducting metal material; the conveying pipeline 1 is made of stainless steel pipe, carbon steel pipe, heat-resistant steel pipe or alloy steel pipe. The protective casing 5 is a stainless steel pipe, a carbon steel pipe, an aluminum pipe or a hard plastic pipe.

[0038] The graphene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com