Diesel engine lubricating oil supply system and supply control method

A supply system and control method technology, applied in closed-circuit lubrication system, lubricant temperature control, engine lubrication, etc., can solve the problems of bulky lubricating oil pump, unfavorable compact design of diesel engine, high power consumption of the system, etc., and achieve optimal supply The effect of oil redundancy, improvement of insufficient oil supply, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

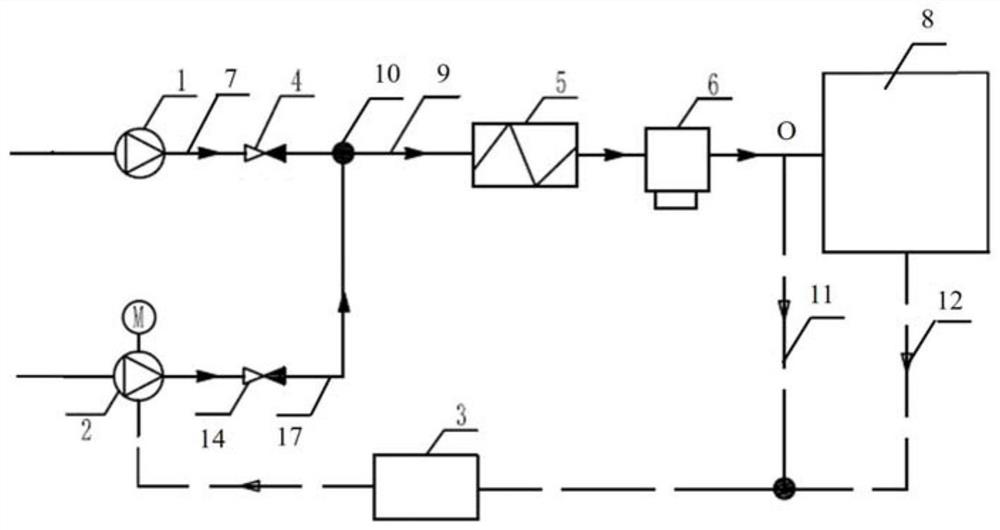

[0081] like figure 1 As shown, the application provides a diesel engine lubricating oil supply system, which includes: diesel engine 8, main road oil pipe 9, main pump 1, auxiliary pump 2, electronic control system 3, first check valve 4 (also known as main check valve 4) One-way valve), second one-way valve 14 (also known as auxiliary one-way valve), main pump oil supply pipeline 7, auxiliary pump oil supply pipeline 17, oil cooler 5, filter 6 and other components.

[0082] Wherein, the main road oil pipe 9 is connected with the diesel engine 8, and is used to supply the diesel engine 8 with lubricating oil, so as to lubricate the friction pairs of the diesel engine 8.

[0083] The main pump 1 supplies lubricating oil in one direction to the main oil pipe 9 through the main pump oil supply pipeline 7 , which is realized by the first one-way valve 4 arranged on the main pump oil supply pipeline 7 . The flow direction of the lubricating oil supplied by the main pump 1 is as fo...

Embodiment 2

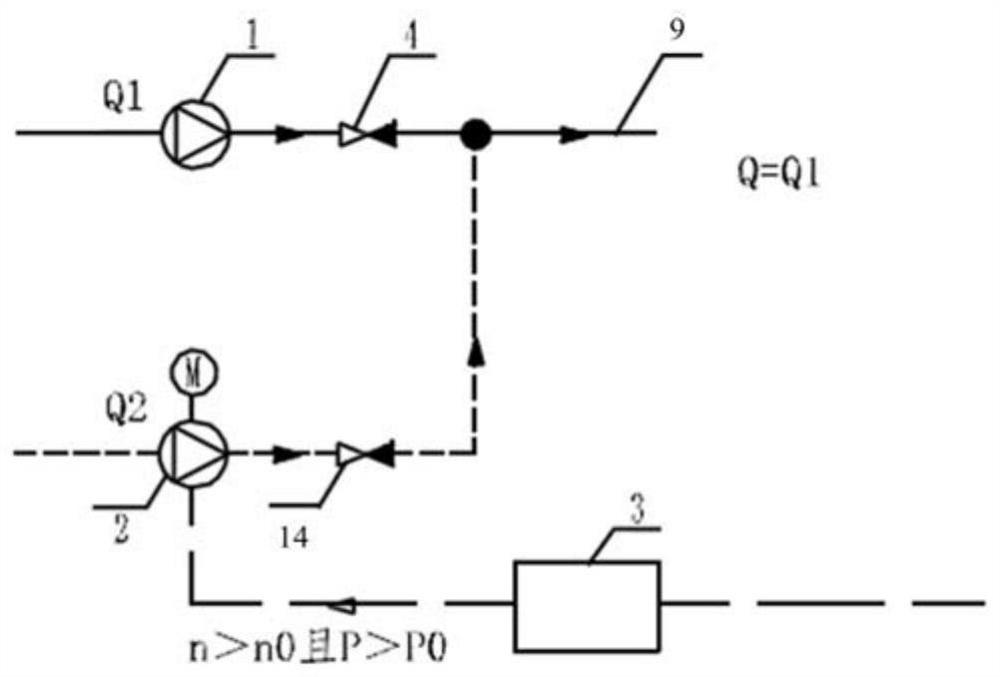

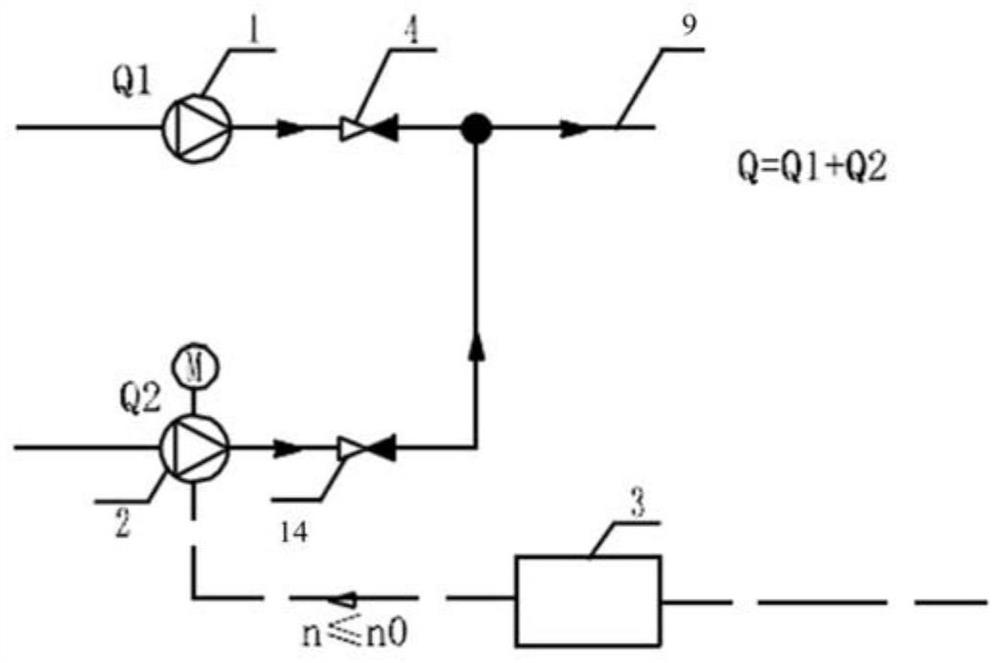

[0110] This embodiment provides a diesel engine lubricating oil supply control method, the basic principle of which is: the main pump and the auxiliary pump are arranged independently, and different opening and closing mechanisms are adopted. The main pump is driven by the crankshaft of the diesel engine and moves under the driving action of the transmission gear. The auxiliary pump is an electric pump, which is controlled and adjusted by the electric control system 3 . The outlets of the two pumps are equipped with one-way valves. The lubricating oil is mixed from the oil supply pipeline of the main pump and the oil supply pipeline of the auxiliary pump respectively through the check valves and then in the main oil pipeline. After the cooler and filter, it enters the diesel engine. According to the preset control strategy, the electronic control system controls the opening and closing of the auxiliary pump to realize the coordinated oil supply of the main and auxiliary pumps...

Embodiment 3

[0121] In this embodiment, the main pump adopts an external gear pump, which is driven by the crankshaft through the transmission gear, and can independently supply lubricating oil for the diesel engine under high working conditions. Redundancy optimization. The auxiliary pump adopts a flow rate of 20m 3 / h, a fixed-frequency electric pump with a power consumption of 3.09kW, is controlled by the electronic control system to turn it on or off in different situations through a preset control strategy.

[0122] After calculation and evaluation, in the diesel engine lubricating oil supply system of this embodiment, compared with the scheme before the transformation according to the scheme of the present invention, the volume of the main pump of this embodiment is reduced by 19.5%, the average power consumption of the system is reduced by 28.6%, and the idle speed Under working conditions, the oil inlet pressure increases by 18.6%. The results show that the lubricating oil supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com