Novel combined type high and large formwork steel platform

A combined and platform technology, which is applied in the connection of formwork/formwork/work frame, hydroelectric power generation, and on-site preparation of building components. Concrete frame column assembly and other issues to achieve the effect of improving stability and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

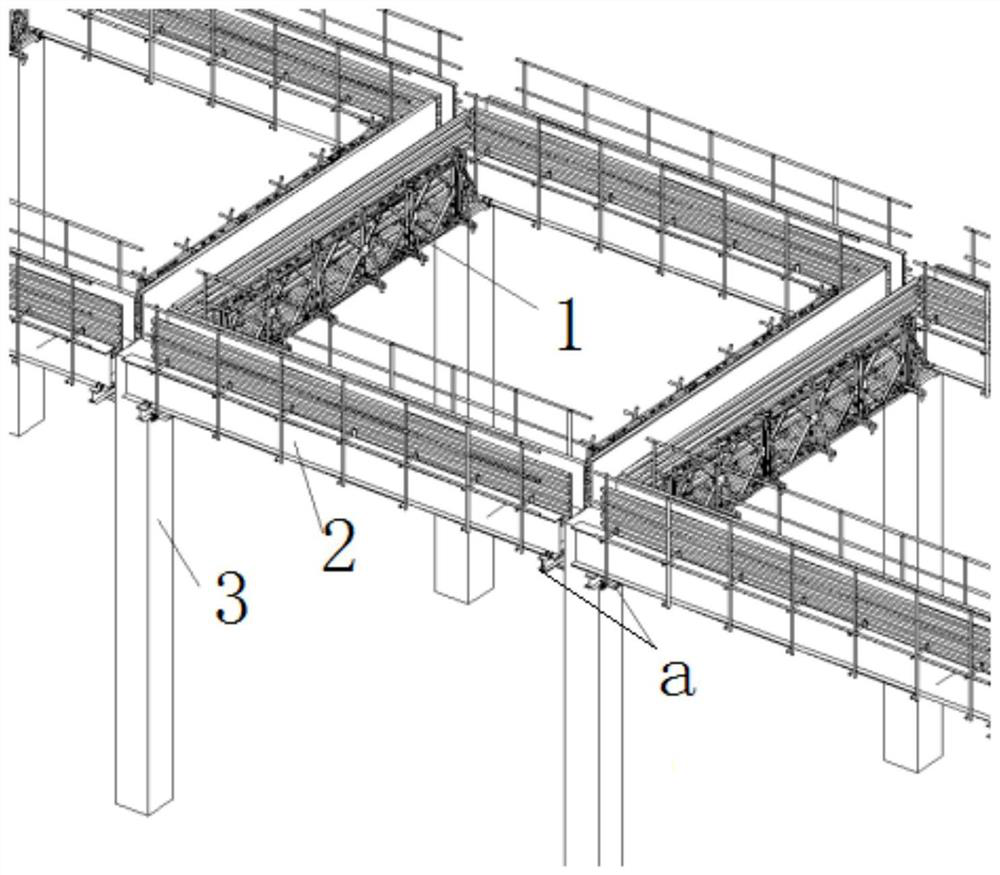

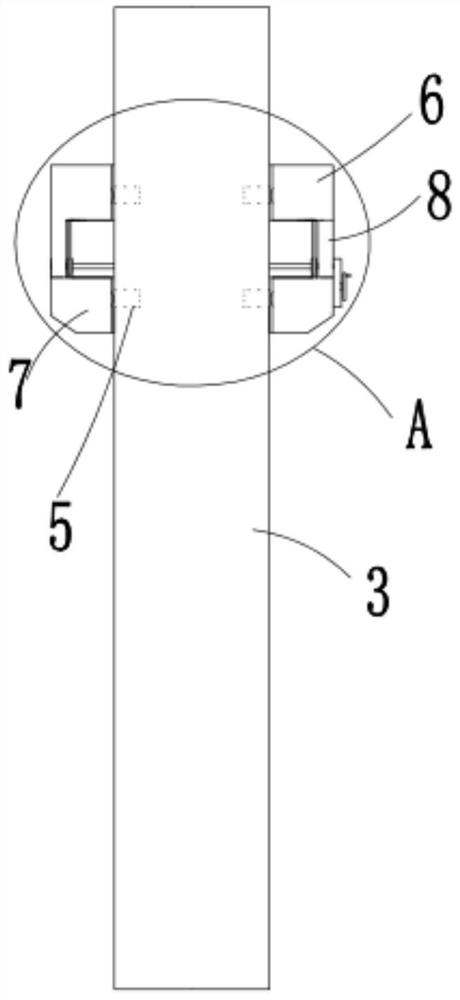

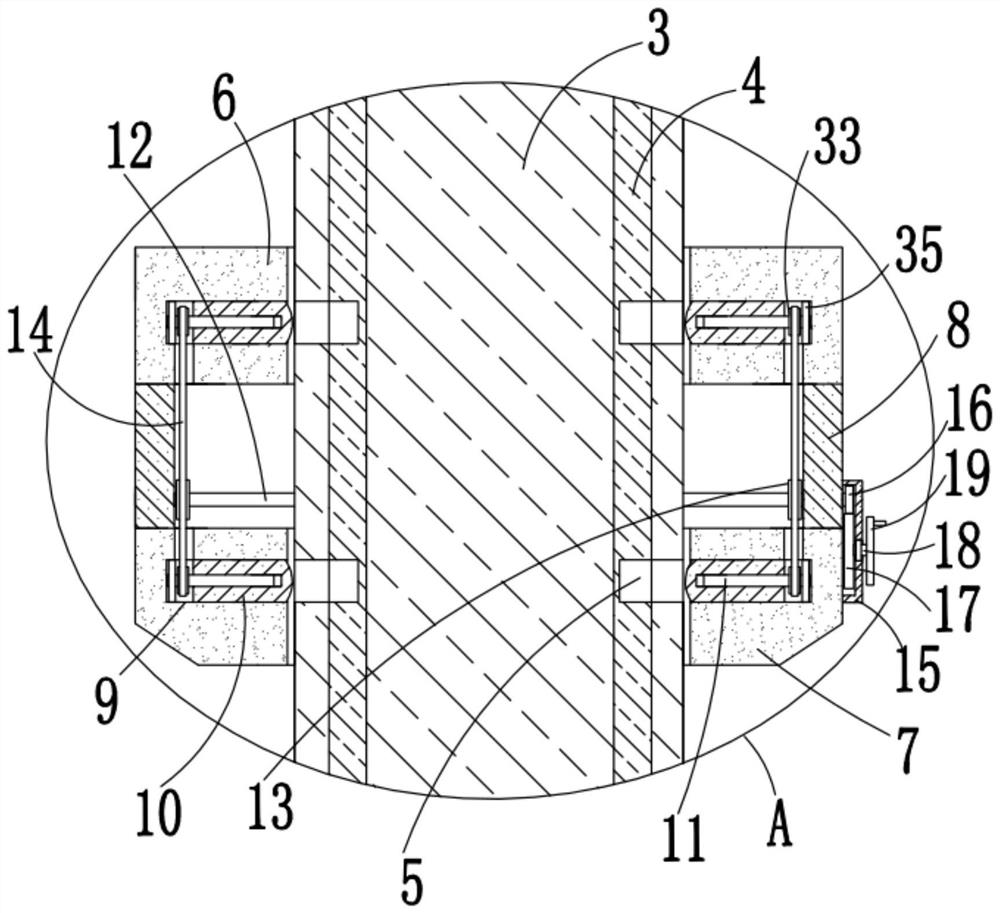

[0038] refer to Figure 2-6 , the present embodiment proposes a novel combined tall and large formwork steel platform, including the combined tall and large formwork steel platform body, the combined tall and large formwork steel platform body includes a plurality of concrete frame columns 3, two adjacent concrete The same concrete frame secondary beam steel structure platform 2 is set between the frame columns 3, and the same concrete frame main beam steel structure platform 1 and concrete frame secondary beam steel structure platform 2 are set between the two opposite concrete frame columns 3 Both the front bottom and the rear bottom of the platform are fixed with H-shaped steel, and the two sides of the concrete frame main beam steel structure platform 1 are fixed with Bailey frames, which are hung and fixed on the lower part of the corresponding H-shaped steel by high-strength bolts. On the flange, a steel casing 4 is pre-embedded in the concrete frame column 3, and two cl...

Embodiment 2

[0044] refer to Figure 7-10, the present embodiment is based on the first embodiment, and its difference from the first embodiment is that: the U-shaped support 6 can also be provided with a co-drive lateral augmentation support mechanism matched with the quick-loading mechanism, and the co-drive The horizontal expansion support mechanism includes rectangular plates 20 respectively embedded on both sides of the U-shaped support 6. Both sides of the U-shaped support plate 8 are provided with second grooves for openings on the front side, the rear side and the top. The bottom inner wall of the second groove is fixedly connected to the bottom of the corresponding rectangular plate 20. The side of the rectangular plate 20 away from the corresponding concrete frame column 3 is provided with a rectangular groove 21. Among the two first screw rods 11, the ends of the upper two first screw rods 11 that are far away from each other are fixedly connected with a round shaft 22, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com