Conductive film repairing method

A conductive film and conductive grid technology, which is applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems of conductive grid disconnection, uneven filling of conductive ink, micro deformation of base film, etc., and achieve High reliability, excellent uniformity of resistivity, and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

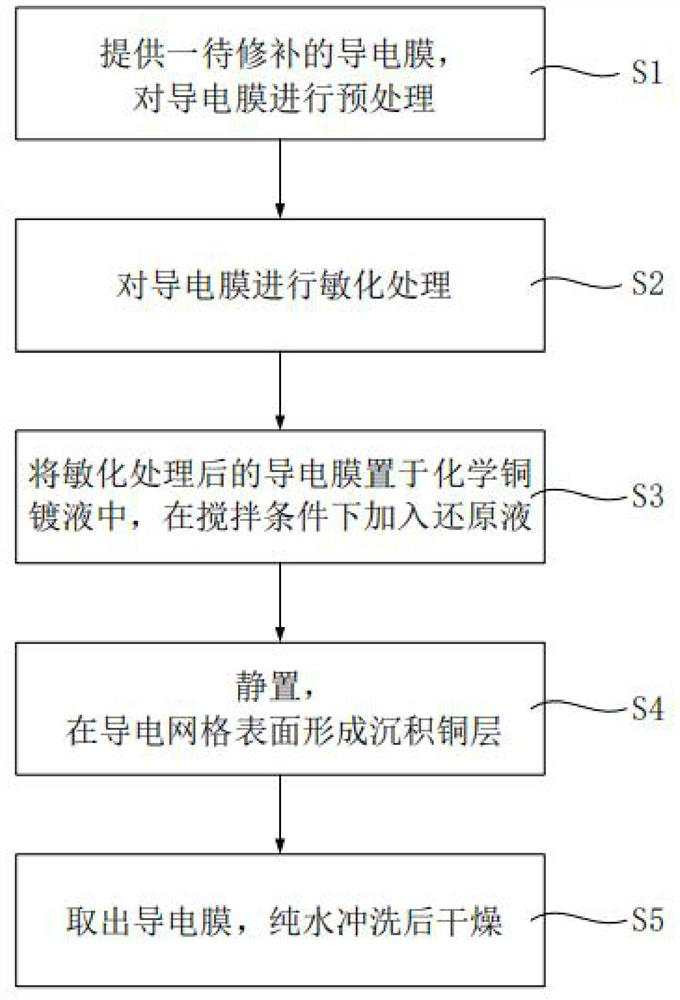

Method used

Image

Examples

Embodiment 1

[0041] The mixed chemical solution 30 of the present embodiment is composed of the following substances in terms of mass percentage: copper sulfate 1.2%, potassium sodium tartrate 1.0%, sodium hydroxide 1.2%, formaldehyde 1.0%, and the temperature of the mixed chemical solution 30 is controlled to be 30-35 ℃, let stand for 1h.

Embodiment 2

[0043] The mixed chemical solution 30 of the present embodiment is composed of the following substances in terms of mass percentage: copper sulfate 1.2%, potassium sodium tartrate 1.0%, sodium hydroxide 1.2%, formaldehyde 1.0%, and the temperature of the mixed chemical solution 30 is controlled to be 35-40 ℃, let stand for 1h.

Embodiment 3

[0045] The mixed chemical solution 30 of the present embodiment is composed of the following substances in terms of mass percentage: copper sulfate 1.2%, potassium sodium tartrate 1.0%, sodium hydroxide 1.2%, formaldehyde 1.3%, and the temperature of the mixed chemical solution 30 is controlled to be 30-35 ℃, let stand for 1h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com