A kind of film removing agent for IC carrier board and application thereof

A technology of removing film agent and carrier plate, which is applied in the directions of detergent composition, detergent compounding agent, surface active detergent composition, etc. It can solve the problems of poor film removal effect, sheet line falling off, and inability to remove film by the same process. , to achieve the effect of high removal efficiency and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

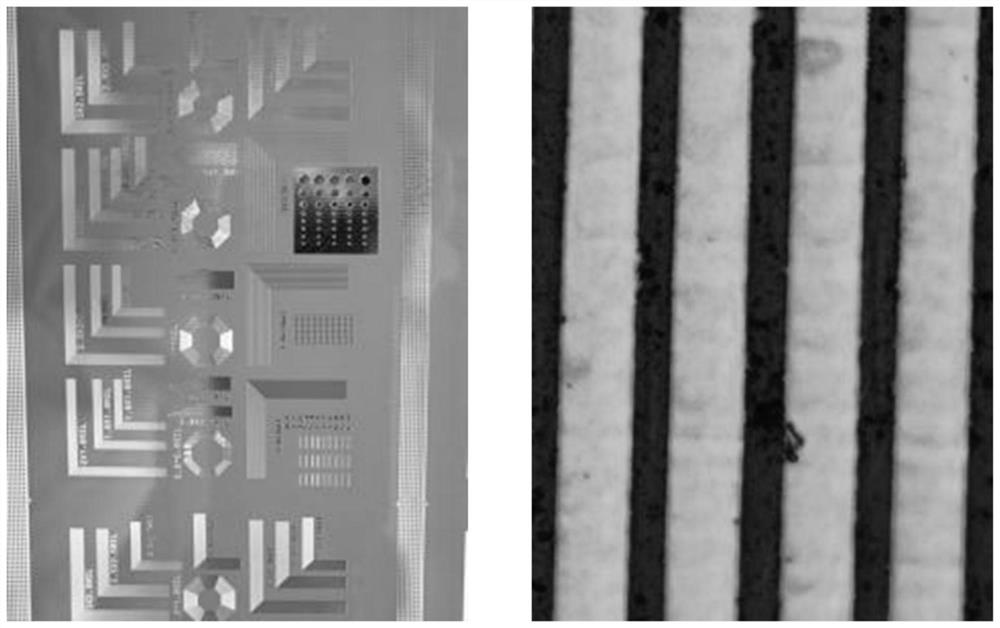

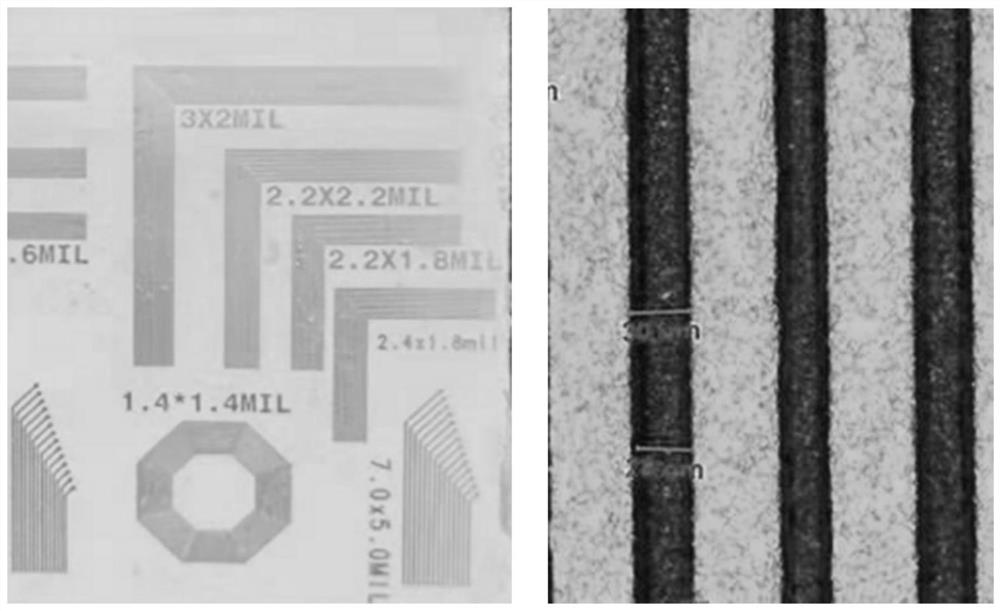

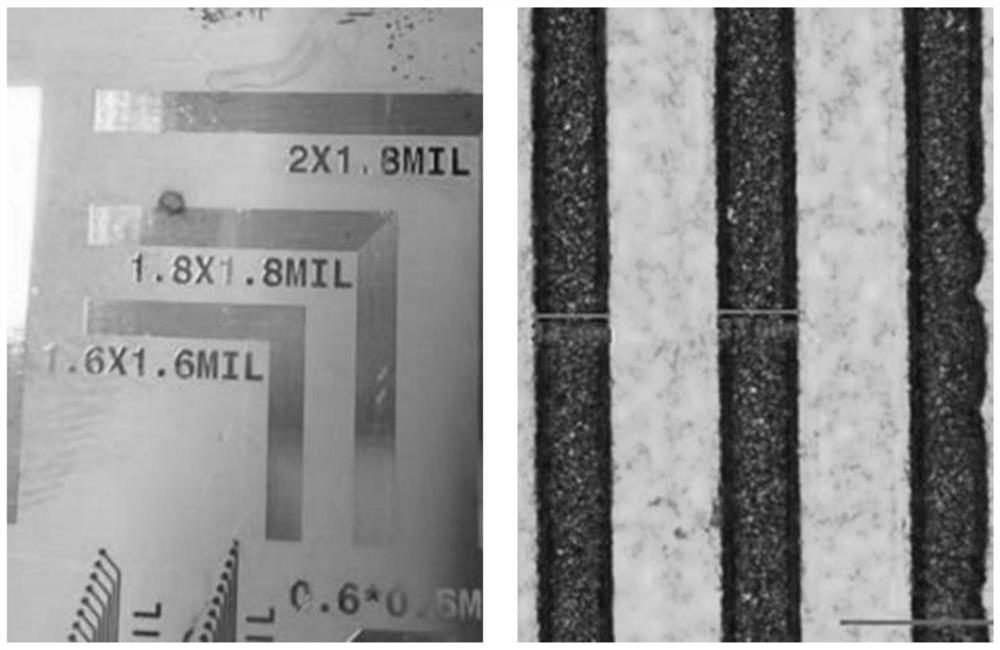

Image

Examples

Embodiment 1

[0037] An embodiment of the film remover for IC substrates of the present invention includes the following components in mass percentage: 15% film remover A, 9% film remover B and the remainder of water; the film remover A Comprising the following components in mass percentage: 13% sodium hydroxide, 12% potassium hydroxide, 5% sodium carbonate, 22% triethylenetetramine, 5% dimethylamine, 8% ethylene glycol monobutyl ether and the rest Measure water; the film remover B includes the following components in mass percentage: 3% polyoxypropylene glyceryl ether, 9% dimethyl phosphoric acid aminomethanesulfonic acid, 2% polynaphthaldehyde sulfonic acid sodium salt, 8% 2-hydroxyphosphonoacetic acid, 2% N-lauroyl sarcosine, 0.8% iminodiacetic acid, 25% triethylamine and the balance water.

Embodiment 2

[0039] An embodiment of the film remover for IC substrates of the present invention includes the following components in mass percentage: 20% film remover A, 5% film remover B and the remainder of water; the film remover A Comprising the following components in mass percentage: 14% sodium hydroxide, 11% potassium hydroxide, 5% sodium carbonate, 20% triethylenetetramine, 2% tetraethylenepentamine, 6% dimethylamine, 10% ethyl Glycol monobutyl ether and the remaining amount of water; the film remover B includes the following components in mass percentage: 3% polyoxypropylene glyceryl ether, 10% dimethyl phosphoric acid, 2.3% polynaphthaldehyde Sulfonic acid sodium salt, 5% 2-hydroxyphosphonoacetic acid, 3% S-carboxyethylsulfosuccinic acid, 1% N-lauroyl sarcosine, 0.9% iminodiacetic acid, 28% triethylamine and other Measure water.

Embodiment 3

[0041]An embodiment of the IC carrier film remover of the present invention includes the following components in mass percentage: 12% film remover A, 10% film remover B and the remainder of water; the film remover A Comprising the following components in mass percentage: 13% sodium hydroxide, 13% potassium hydroxide, 5% sodium carbonate, 23% tetraethylenepentamine, 6% dimethylamine, 10% ethylene glycol monobutyl ether and the rest Measure water; the film remover B includes the following components in mass percentage: 3.5% polyoxypropylene glyceryl ether, 9% dimethyl phosphoric acid aminomethanesulfonic acid, 1% polynaphthaldehyde sulfonic acid sodium salt, 1% Sodium N-oleoylmethyl taurate, 9% 2-hydroxyphosphonoacetic acid, 1% N-lauroyl sarcosine, 0.4% iminodiacetic acid, 0.3% tetrasodium glutamate diacetate, 20% trisodium Ethylamine and the remainder of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com