A treatment device and method for streptomycin residue

A streptomycin bacteria and slag treatment technology, which is applied in biomass post-treatment, biomass pre-treatment, biochemical cleaning devices, etc. problem, to achieve the effect of stable nature and optimized reaction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

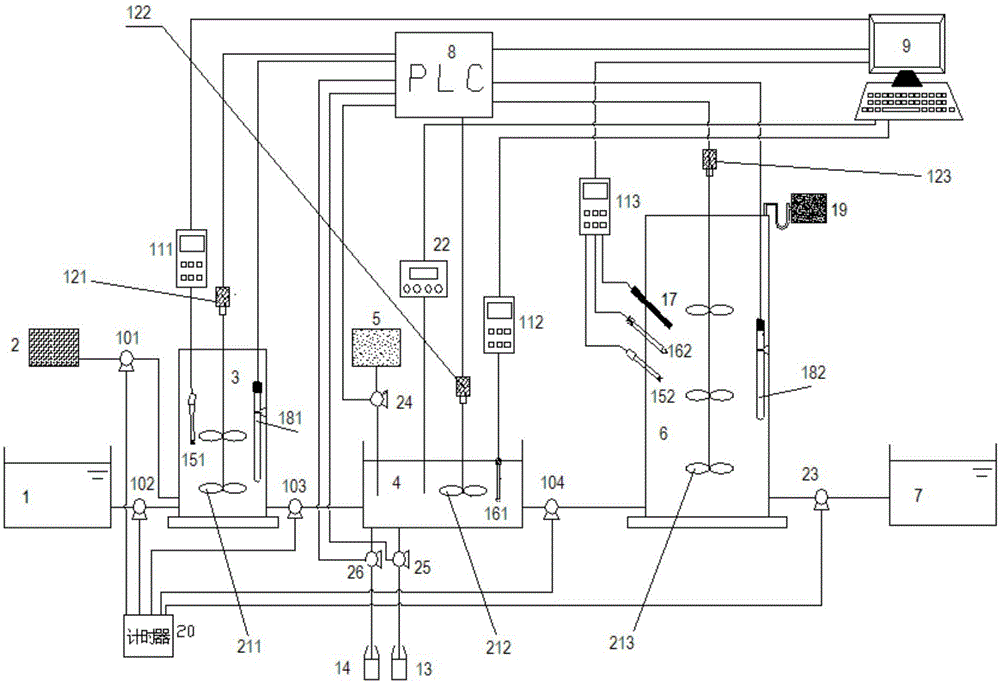

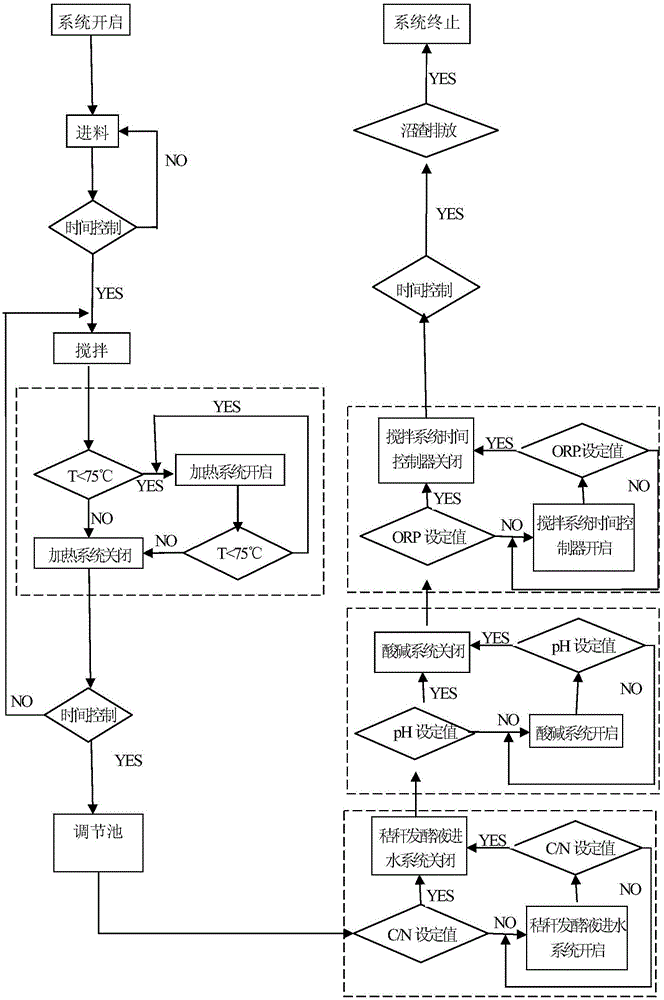

[0055] Take 2L of streptomycin slag and add it to the streptomycin slag storage tank, set the feed amount to 5% of the volume of the anaerobic ASBR reactor (6), and add 0.15mol / L NaOH lye to the alkali tank (14); through the PLC automatic control system (8) to control the opening of the streptomycin slag storage tank (1) and the alkali adding pump (26), the feeding time is set to 5min, and the flow rates are 0.05L / min and 0.001L respectively / min, the mass ratio of lye and streptomycin slag in the pre-reaction zone was 0.08gNaOH / g streptomycin slag at this time; the electric stirrer one (121) in the pre-reaction tank (3) was opened, and the heating rod One (181) starts heating, uses the online water quality monitoring system one (111) to detect the actual temperature in the pre-reaction tank (3), and feeds back to the PLC automatic control system, when the temperature is lower than 75°C, the heating rod one (181) starts heating , when the temperature reaches 75°C, the heating ...

Embodiment 2

[0057] Take 2L of streptomycin slag and add it to the streptomycin slag storage tank, set the feed amount to 4.5% of the volume of the anaerobic ASBR reactor (6), and add 0.15mol / L NaOH lye to the alkali tank (14); through the PLC automatic control system (8) to control the opening of the streptomycin slag storage tank (1) and the alkali adding pump (26), the feeding time is set to 5min, and the flow rates are 0.05L / min and 0.001 L / min, now the mass ratio of lye and streptomycin slag in the pre-reaction zone is 0.10gNaOH / g streptomycin slag; electric stirrer one (121) in the pre-reaction tank (3) is opened and heated simultaneously Rod 1 (181) starts heating, and uses online water quality monitoring system 1 (111) to detect the actual temperature in the pre-reaction tank (3), and feeds back to the PLC automatic control system. When the temperature is lower than 75°C, heating rod 1 (181) starts Heating, when the temperature reaches 75°C, the heating is stopped, and the stirring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com