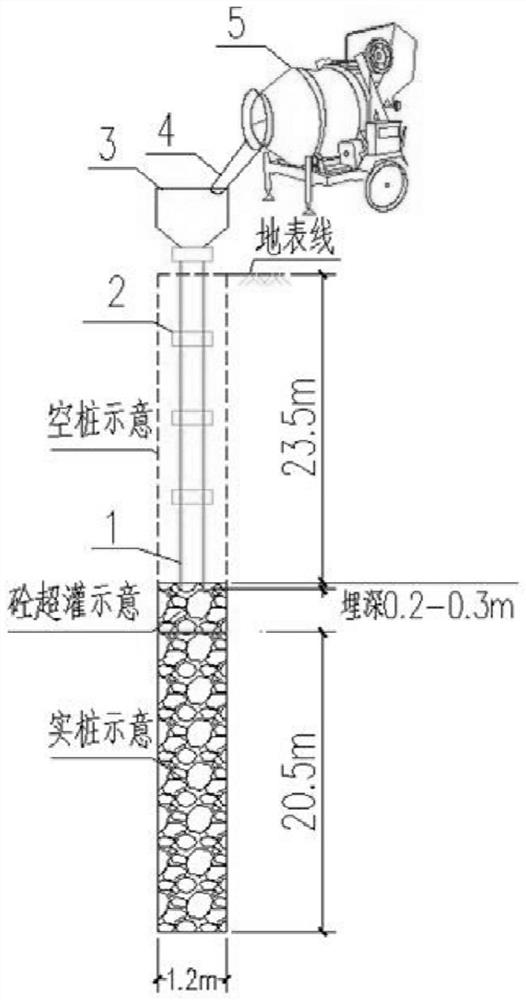

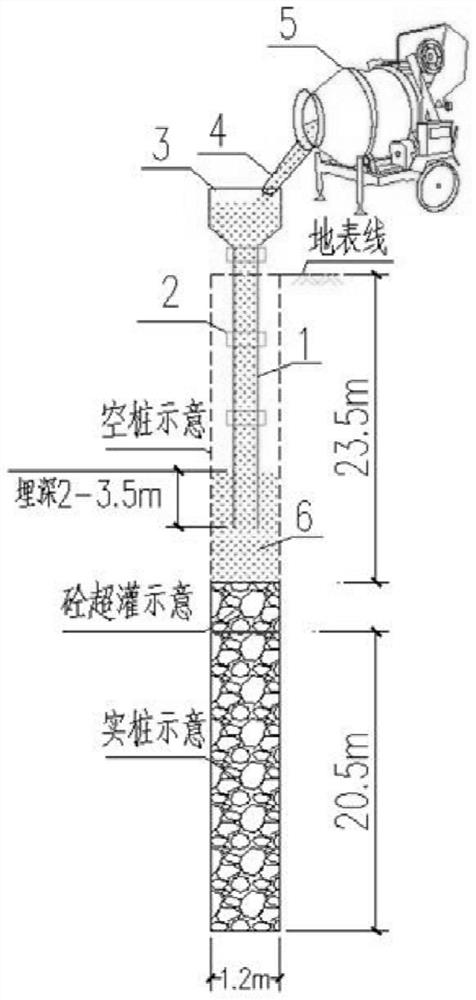

Hollow pile backfill material and method for super-long large-diameter dense pile group in water-rich silty-fine sand layer

A water-rich fine sand layer and large-diameter technology, applied in construction, infrastructure engineering and other directions, can solve the problems of high construction cost, poor economy, hole wall disturbance, etc. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1, a material for backfilling empty piles of super long-diameter dense pile groups in water-rich fine sand layer, including: sand, cement, bentonite, admixture and water, wherein the mass proportion is: sand: 76%, cement: 3.7% %, bentonite: 0.1%, admixture: 0.15%, and the rest is water.

[0027] The sand is a mixture of silt and fine sand and medium-coarse sand produced by drilling piles.

[0028] The cement is 32.5 grade ordinary Portland cement.

[0029] The bentonite is sodium bentonite.

[0030] The admixture is a mixture of construction admixture general master powder.

[0031] The empty pile part filled with this backfill material and method has cohesiveness, self-stability and low permeability after the final setting of cement (8~12h), which can ensure that the mud does not seep laterally during the hole forming process of adjacent piles. Leakage to ensure the stability of the hole wall. In addition, the average unconfined compressive strength of the ...

Embodiment 2

[0032] Example 2, a material for backfilling empty piles with super long-diameter dense pile groups in water-rich powder fine sand layer, including: sand, cement, bentonite, admixture and water, wherein the mass proportion is: sand: 77%, cement: 4.0 %, bentonite: 0.12%, admixture: 0.155%, and the rest is water.

[0033] The sand is a mixture of silt and fine sand and medium-coarse sand produced by drilling piles.

[0034] The cement is 32.5 grade ordinary Portland cement.

[0035] The bentonite is sodium bentonite.

[0036] The admixture is a mixture of construction admixture general master powder.

[0037] The empty pile part filled with this backfill material and method has cohesiveness, self-stability and low permeability after the final setting of cement (8~12h), which can ensure that the mud does not seep laterally during the hole forming process of adjacent piles. Leakage to ensure the stability of the hole wall. Moreover, the average unconfined compressive strength ...

Embodiment 3

[0038] Example 3, a material for backfilling empty piles of super long-diameter dense pile groups in water-rich fine sand layer, including: sand, cement, bentonite, admixture and water, wherein the mass proportion is: sand: 78%, cement: 4.4 %, bentonite: 0.15%, admixture: 0.16%, and the rest is water.

[0039] The sand is a mixture of silt and fine sand and medium-coarse sand produced by drilling piles.

[0040] The cement is 32.5 grade ordinary Portland cement.

[0041] The bentonite is sodium bentonite.

[0042] The admixture is a mixture of construction admixture general master powder.

[0043] The empty pile part filled with this backfill material and method has cohesiveness, self-stability and low permeability after the final setting of cement (8~12h), which can ensure that the mud does not seep laterally during the hole forming process of adjacent piles. Leakage to ensure the stability of the hole wall. Moreover, the average unconfined compressive strength of the 28-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com