Skid-mounted oily sewage treatment device and method

A treatment device and technology for oily sewage, applied in water/sewage treatment, water/sludge/sewage treatment, magnetic field/electric field water/sewage treatment, etc. Production threats and other issues, to achieve the effect of reducing the content of volatile substances and impurities, large processing capacity, and achieving continuous safe mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

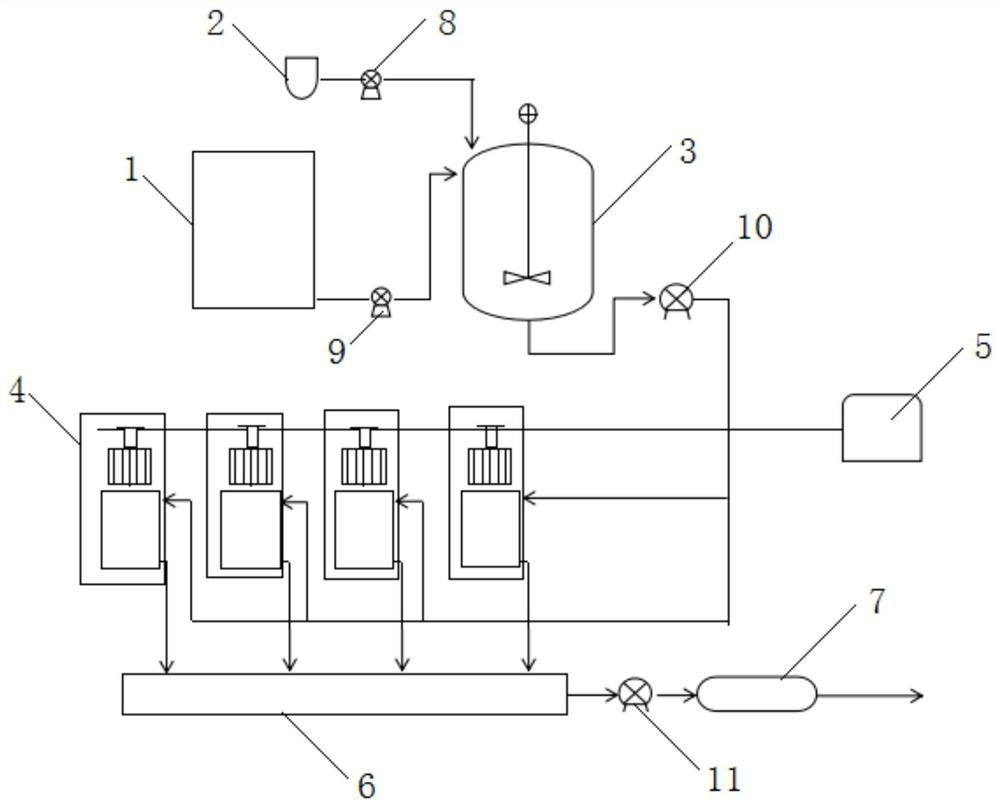

[0018] according to figure 1 , 2 As shown, a skid-mounted oily sewage treatment device, the sewage storage tank 1 and the magnetic Janus particle storage tank 2 are connected to the inlet end of the high-speed shearer 3 through a connecting pipe, and the outlet end of the high-speed shearer 3 is passed through the outlet pump 10 Connect the oil pollution adsorption treatment system 4, the oil-free sewage after the oil pollution separation of the oil pollution adsorption treatment system 4 enters the water storage tank 6, the water storage tank 6 discharges the sewage through the drainage pump 11, and the discharged sewage passes through the filter 7 to filter other After the impurities are removed, the oil-free water is discharged;

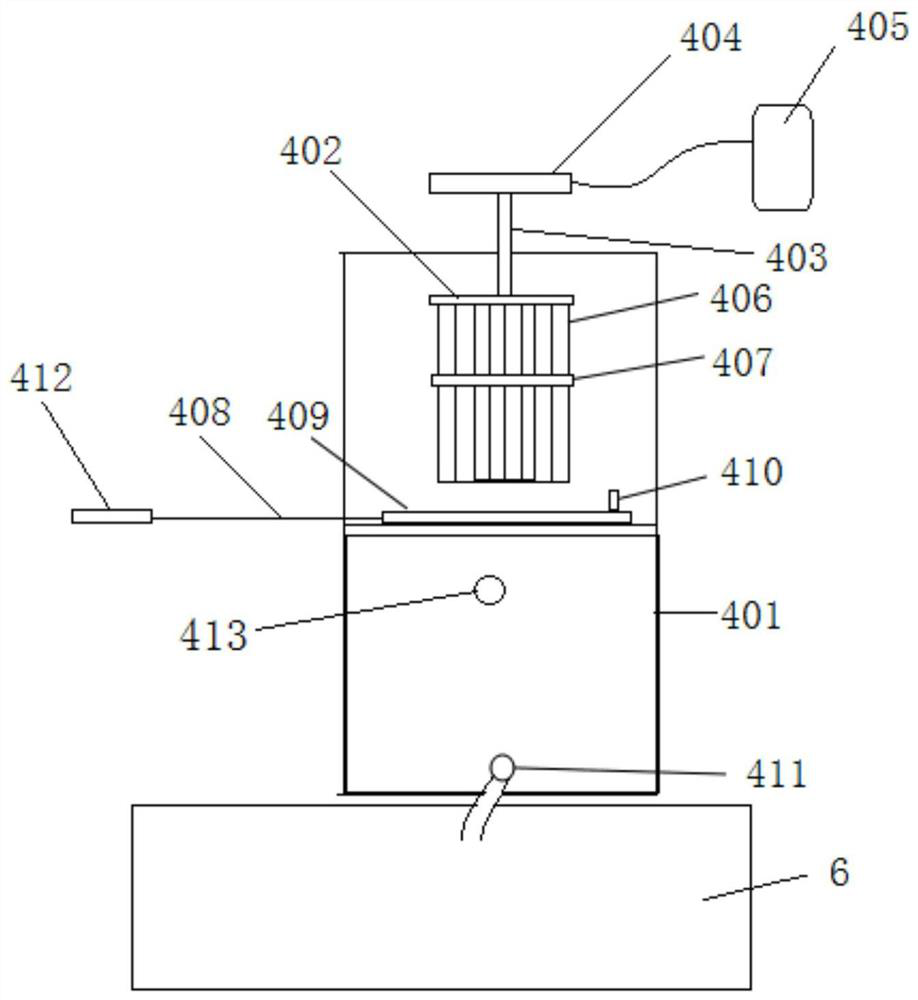

[0019] The oil stain adsorption treatment system 4 includes a magnetic separation barrel 401, an adsorption device installed on the top of the magnetic separation barrel 401, and a collection device installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com