Shell-and-tube heat exchanger manufacturing and machining method

A technology of shell-and-tube heat exchangers and processing methods, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., and can solve the problems of no flexible and adjustable fixing fixtures, mass production operations, and reduced operating process efficiency. , to achieve the effect of improving the clamping range, simple structure and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technique of the present invention, the creation characteristics, the achievement and the efficiency are readily understood, and the present invention is further illustrated in connection with the present invention, and it is to be explained, and the embodiments in the present application are described below. The features in the examples can be combined with each other.

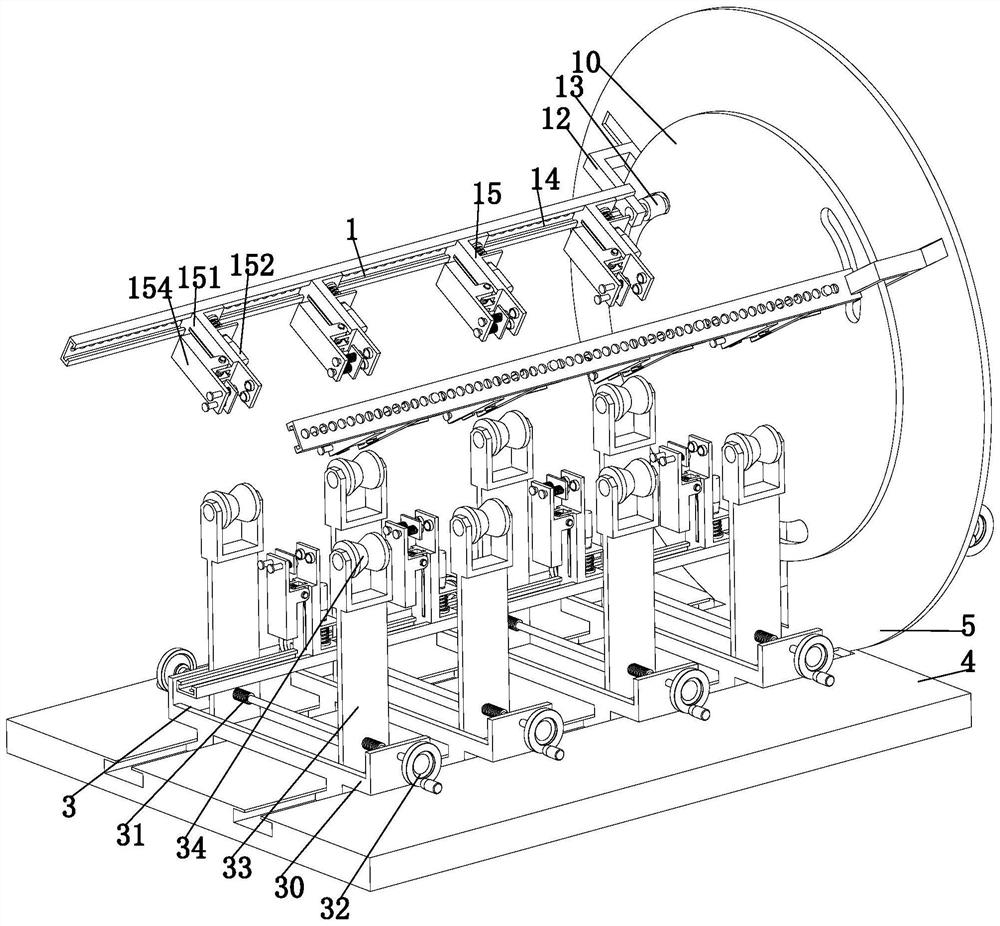

[0033] like Figures 1 to 7As shown, a tube-shell heat exchanger is fabricated, which uses a housing heat exchanger to produce a clamping device including a clamping mechanism 1, a regulating mechanism 2, a subastroenter, a bottom plate 4. And the ring frame 5, the specific method of fabricating processing using the above-mentioned clamping device on the housing heat exchanger is as follows:

[0034] S1, Trust Adjustment: According to the spacing distance of the tube plate and the baffle, adjust the spacing position between the intercondered seats 30, the interlayer sliding seat 30 tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com