Special welding material for austenite high alloy steel and application

A high-alloy steel and austenite technology, which is applied in special welding consumables and application fields for austenitic high-alloy steel, can solve problems such as fatigue damage, high sensitivity to hot cracks, and cumbersome procedures, and achieve excellent strength and obvious reproducibility and the effect of regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1Q690

[0062] Embodiment 1Q690 high-strength structural steel welding test

Embodiment 1

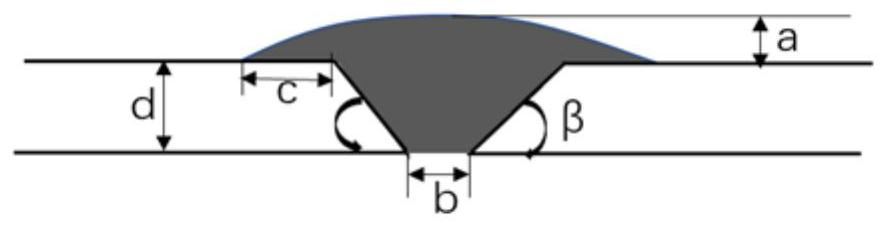

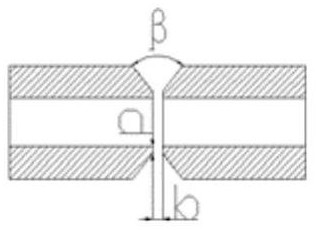

[0063] The process parameters and the results of Example 1 are shown in Table 1. The joint diagram of embodiment 1 is shown in figure 1 .

[0064] Table 1

[0065] Base metal (steel grade) Q690 Yield Strength 753MPa Ultimate strength 792MPa Elongation 21% Joint form Butt joint Groove angle (β) 45° Cover Thickness (a) 2mm gap (b) 2mm Cover extension width (c) 4mm Base metal thickness (d) 5mm other No water, rust, oil, etc. on both sides of the groove Filler metal (welding consumable standard) GB / T29713 Welding material type Cr20Ni10Mn7Si-GQ (special welding consumables for high-strength structural steel) Welding specification Ф1.2mm welding gas Mixed gas (argon 80%, carbon dioxide 20%) Welding parameters Current 210A, voltage 32V Auxiliary process Exempt from heat treatment process (no preheating before welding, slow cooling after welding, complete cold weldi...

Embodiment 2X70

[0067] Embodiment 2 X70 high-strength pipeline steel welding

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com