Aero-engine blade spraying production line and control method

A technology of aero-engine and production line, applied in coating, spray booth, spray device, etc., to achieve the effect of efficient spraying operation, improving spraying drying efficiency, and reliable lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

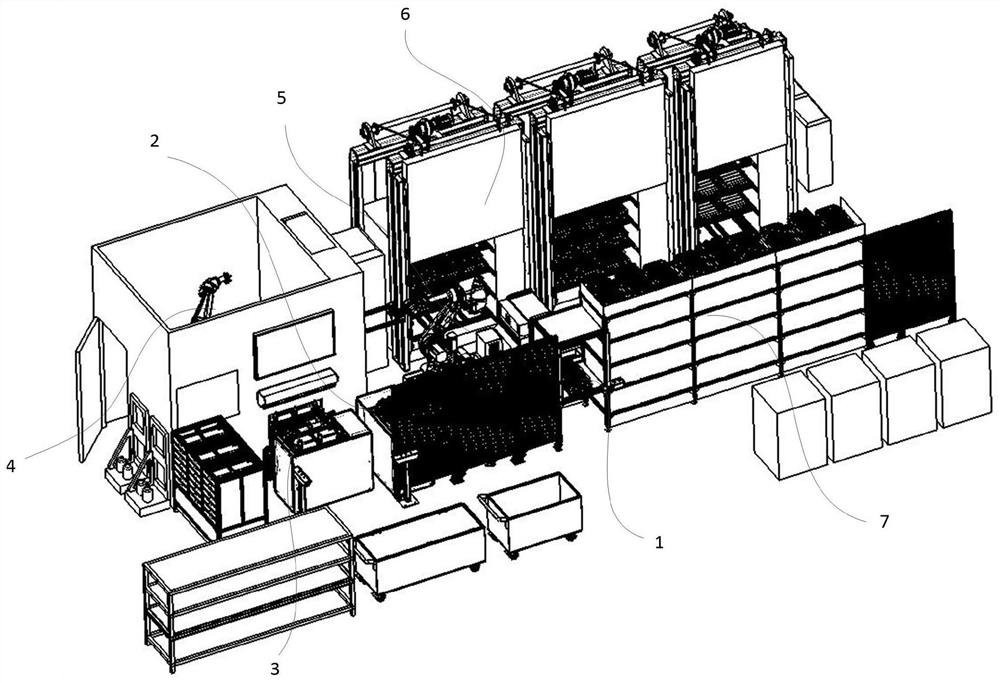

[0050] like Figure 1 to 18 As shown, the present embodiment provides an air engine blade spray drying production line for surface spraying of the blade 8 of the aviation engine. It should be noted that the "first", "second" sequence term used in the present embodiment is only used to distinguish the same type of component, and cannot understand a particular limitation of the scope of protection. Further, as described in the "bottom", "top", "four-week edge", "center", "" bottom "," center ", and" center "," in the present embodiment.

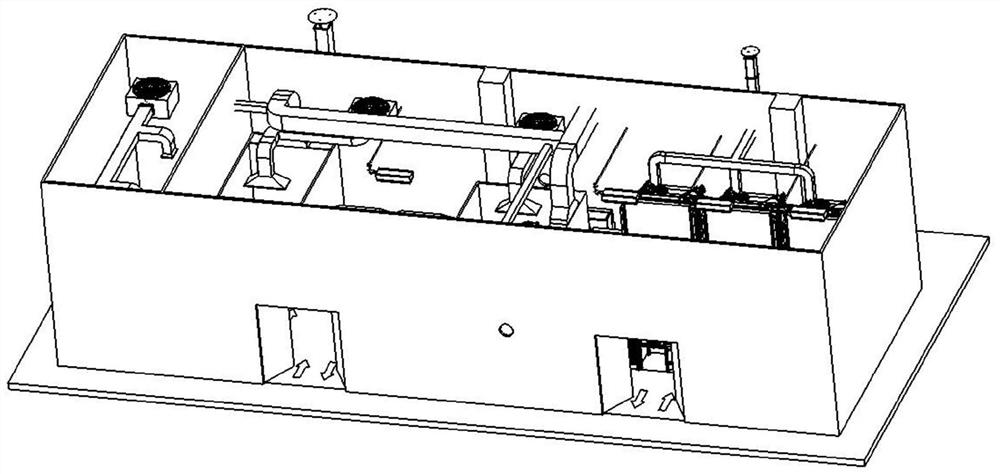

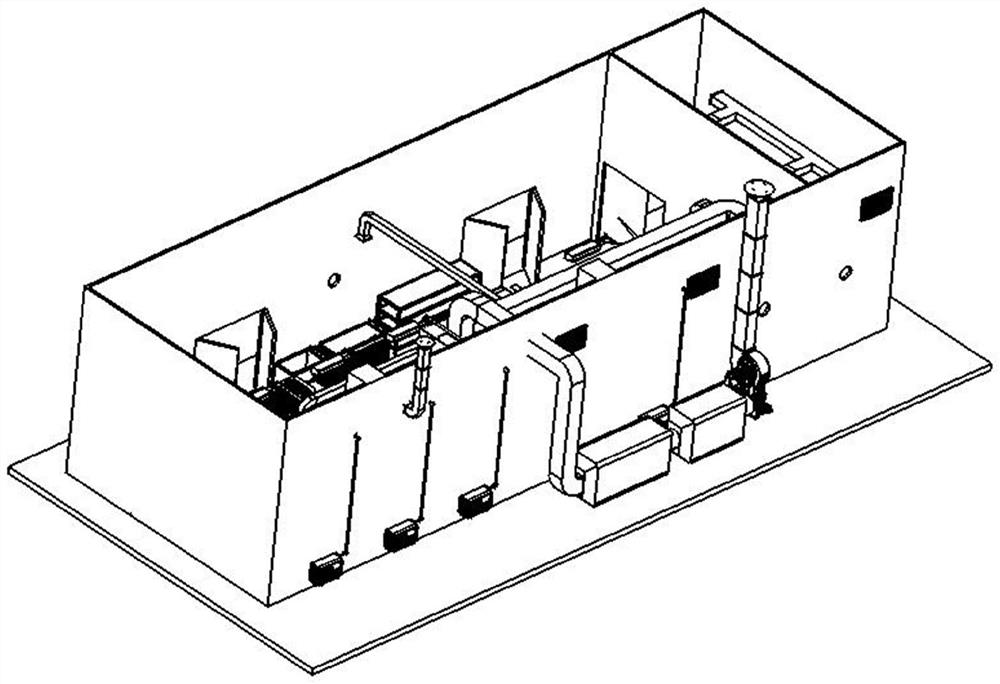

[0051] like Figure 1 to 5 As shown, the air engine blade spray drying production line of the present embodiment is placed in the processing production chamber, and a ventilation purification system is provided at the top of the processed production chamber. Among them, the air engine blade spray drying production line mainly includes blade material plate upper tip 1, first blade material disk transport mechanism 2, second blade material disk transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com