Auxiliary curing device for laying epoxy terrazzo floor

A technology of epoxy grinding stone floor and curing device, which is applied in chemical instruments and methods, fixed filter element filters, separation methods, etc. In the inner wall of the feeding pipe and other problems, the effect of ensuring normal and efficient spraying operations, reducing the number of cleanings and increasing the effective filtration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

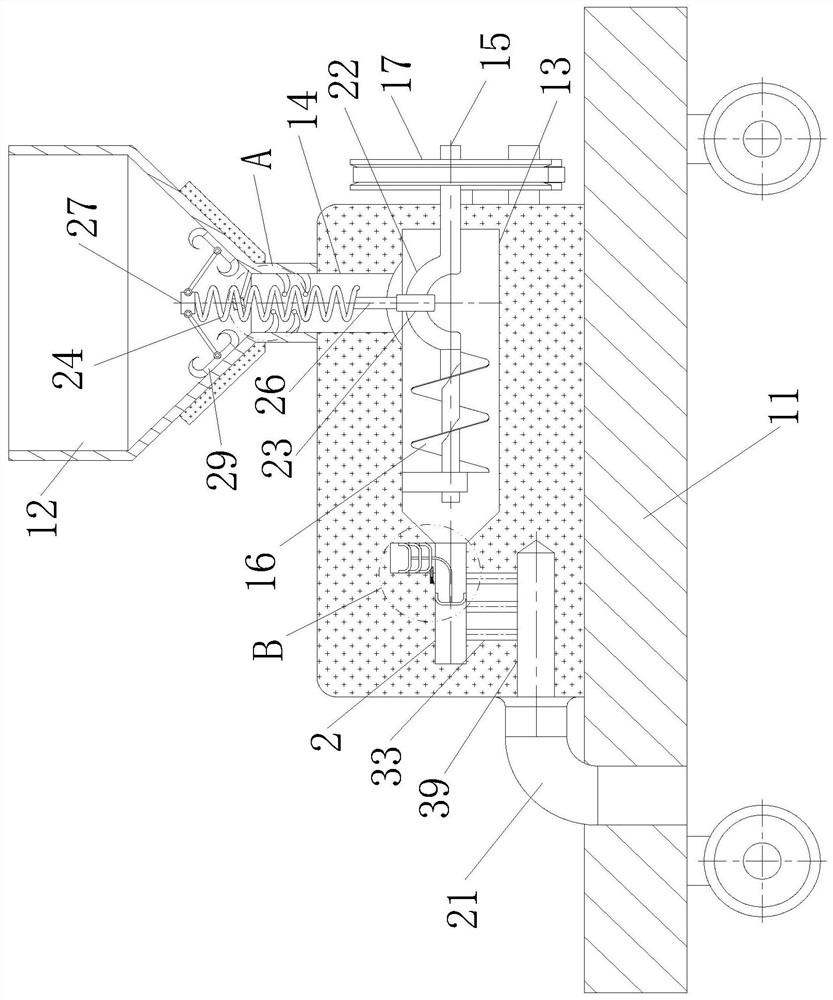

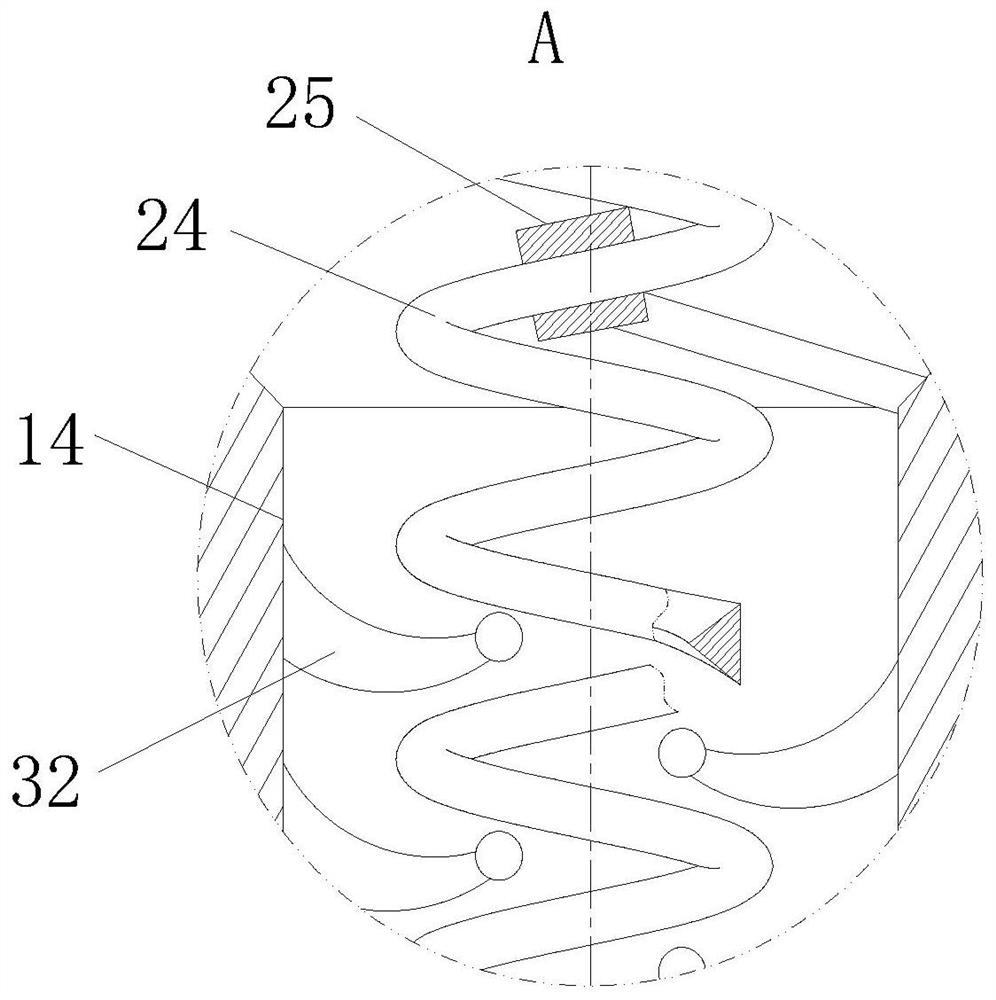

[0030] As an embodiment of the present invention, the spring 24 has a triangular cross-section, and one side of the triangle is attached to the inner wall of the No. 1 hole 14; through the spring 24 with a triangular cross-section, the spring 24 continuously reciprocates up and down in the No. 1 hole 14 When sliding, the triangular corners of the spring 24 constantly scrape the inner wall of the No. 1 hole 14, increasing the separation efficiency of the incompletely solidified curing agent and the No. 1 hole 14 inner wall, and further ensuring the smooth flow of the No. 1 hole 14.

[0031] As an embodiment of the present invention, the two ends of the scraper 29 are provided with horn-shaped elastic sharp corners 3, and a set of clamping units are evenly distributed on the inner circumference of the elastic sharp corners 3; the clamping units include a set of symmetrically arranged The arc-shaped plates 31 are symmetrically arranged in a bracket shape; the inner wall of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com