Workpiece spraying system and spraying method using the same

A workpiece and control component technology, applied in the field of workpiece spraying system, can solve the problems of high labor cost, low labor precision, high labor intensity, etc., and achieve the effect of avoiding harmful gas damage, ensuring health, and realizing automatic transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. Detailed instructions:

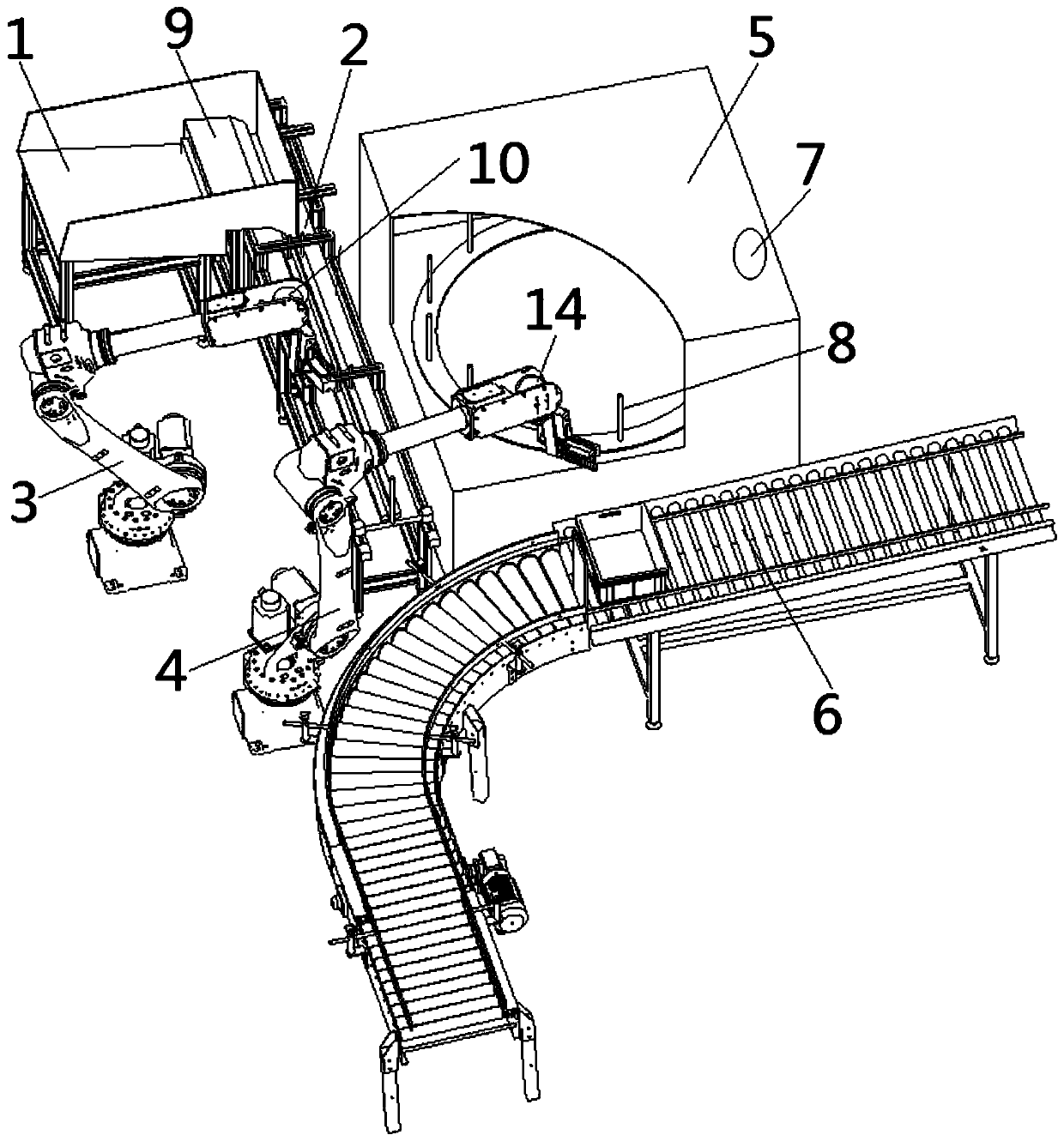

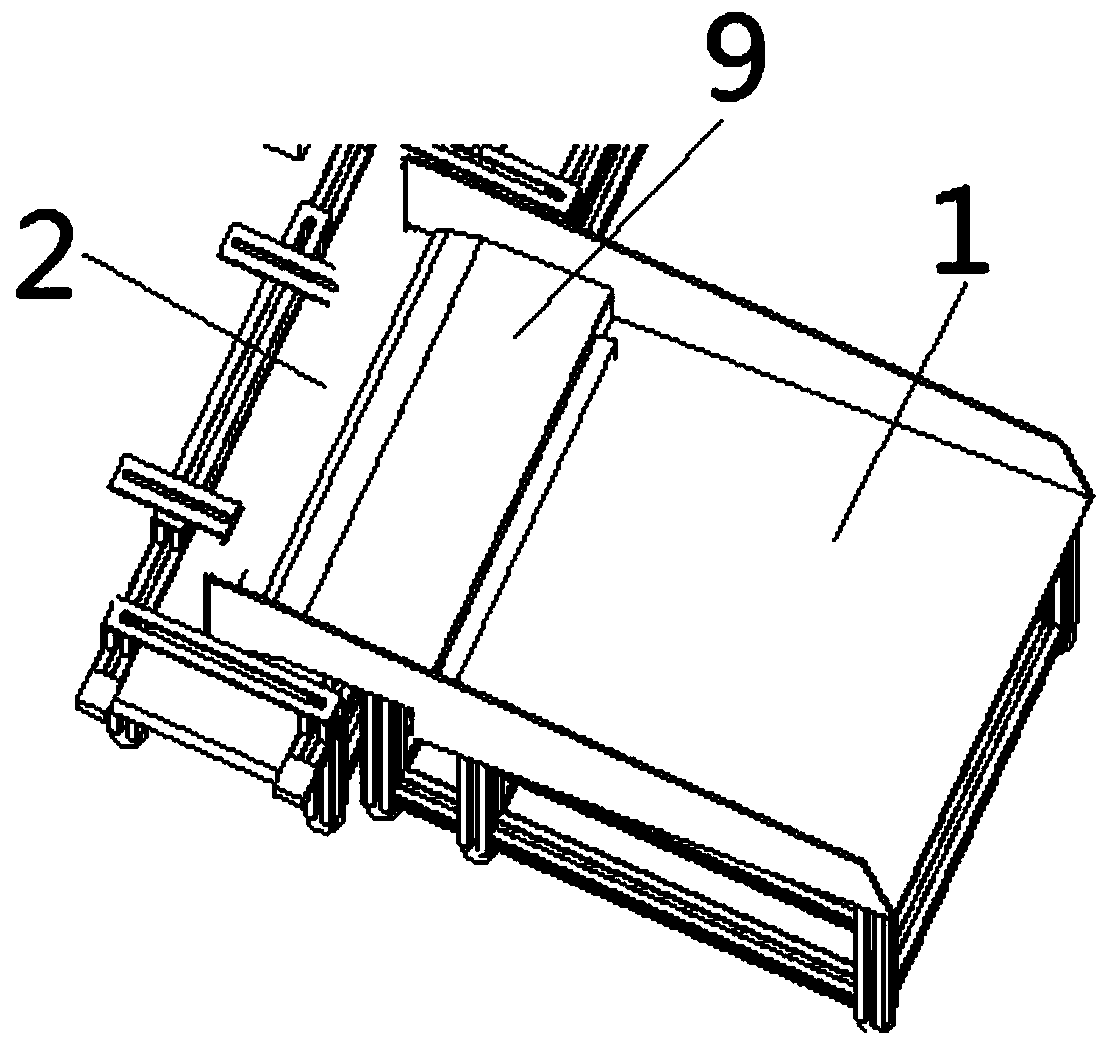

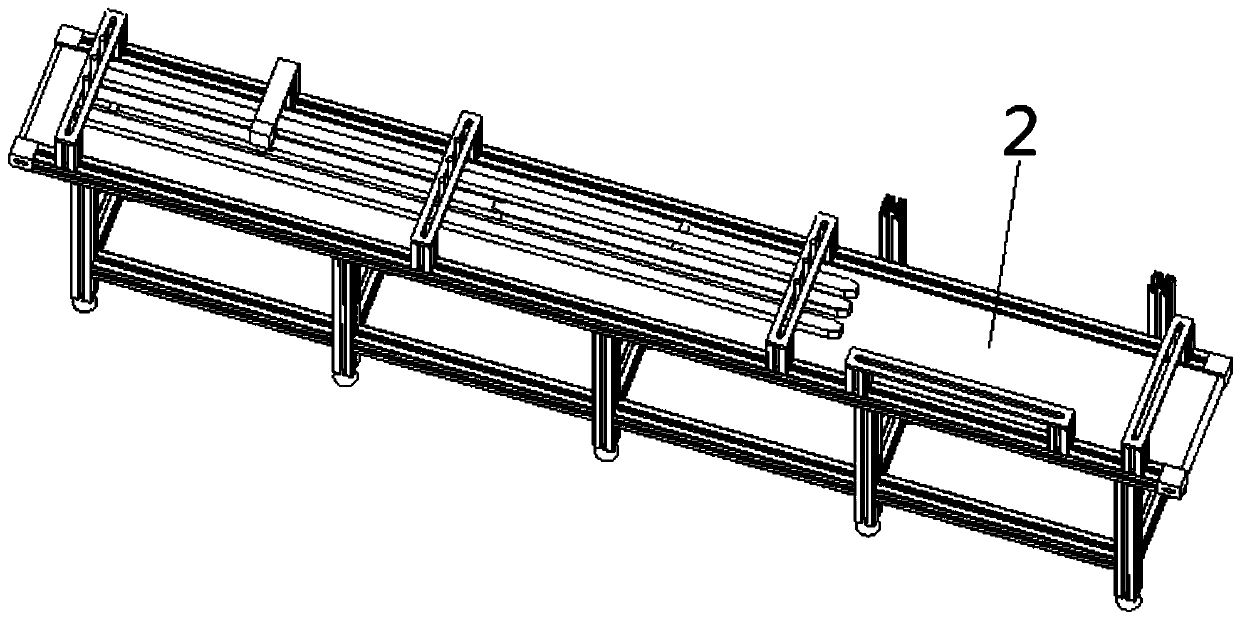

[0027] as attached figure 1 - attached Figure 6As shown, the present invention is a kind of workpiece spraying system, and described workpiece spraying system comprises feeding machine 1, conveyor 2, loading robot 3, unloading robot 4, spraying furnace 5, and conveyor 2 is arranged near the spraying furnace 5 position, one end of the conveyor 2 is close to the position of the loading machine 1, the other end of the conveyor 2 extends to the position close to the spraying furnace 5 and the unloading robot 4, the loading robot 3 and the unloading robot 4 are set near the spraying furnace 5, close to the The blanking r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com