Rotary filter screen manual turning gear

A manual cranking and rotating filter technology is applied in the field of nuclear power plant maintenance, which can solve problems such as hidden safety hazards, the separation of the crank handle and the motor shaft to hurt people or equipment, and the damage to the rotating filter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

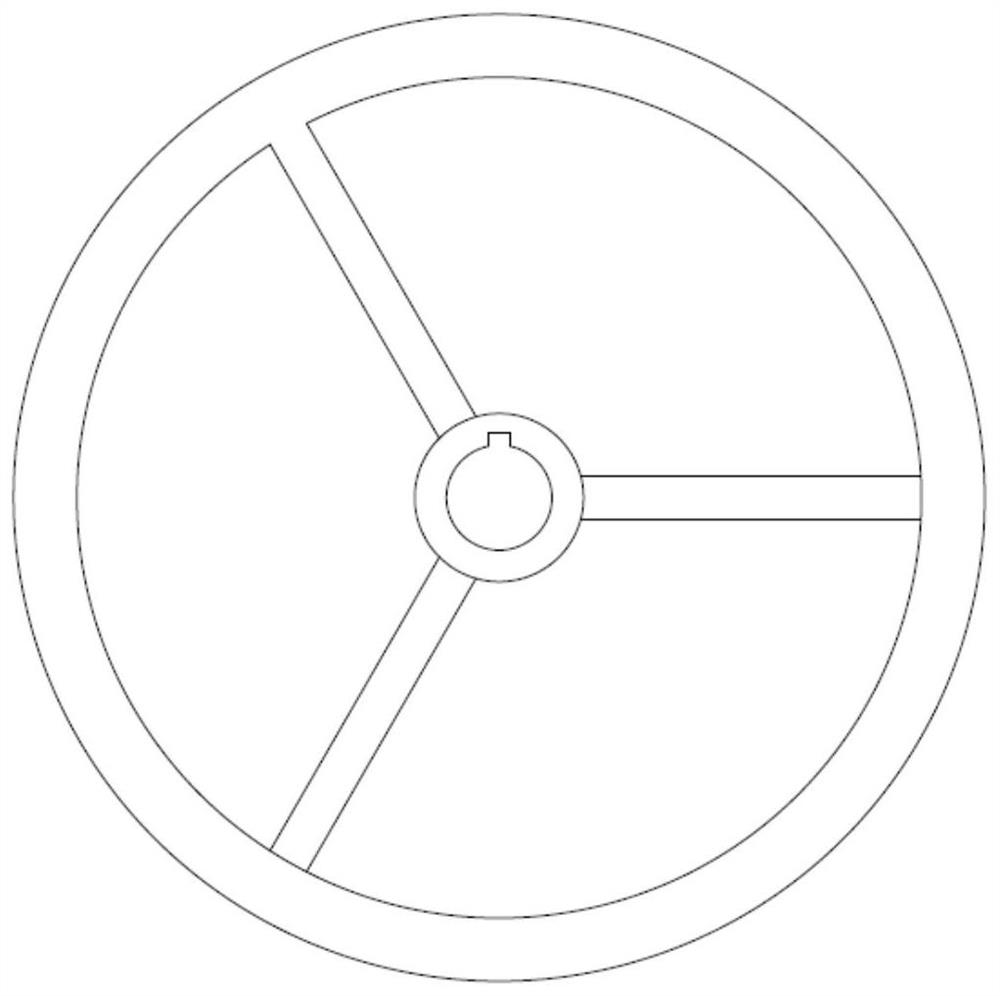

[0035] Such as figure 1 As shown, it is a traditional turning handwheel in the prior art. A keyway is provided at the edge of the center hole of the turning handwheel. The keyway corresponds to the keyway on the motor shaft. Through the keyway on the turning handwheel and the motor shaft The key that matches the keyway on the top is fixedly connected to the turning hand wheel on the motor shaft.

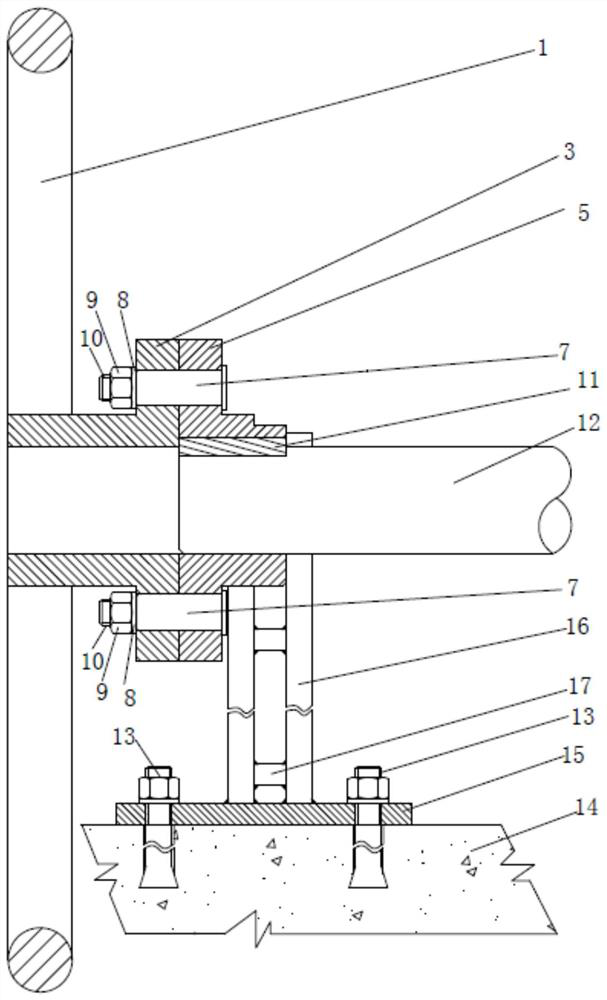

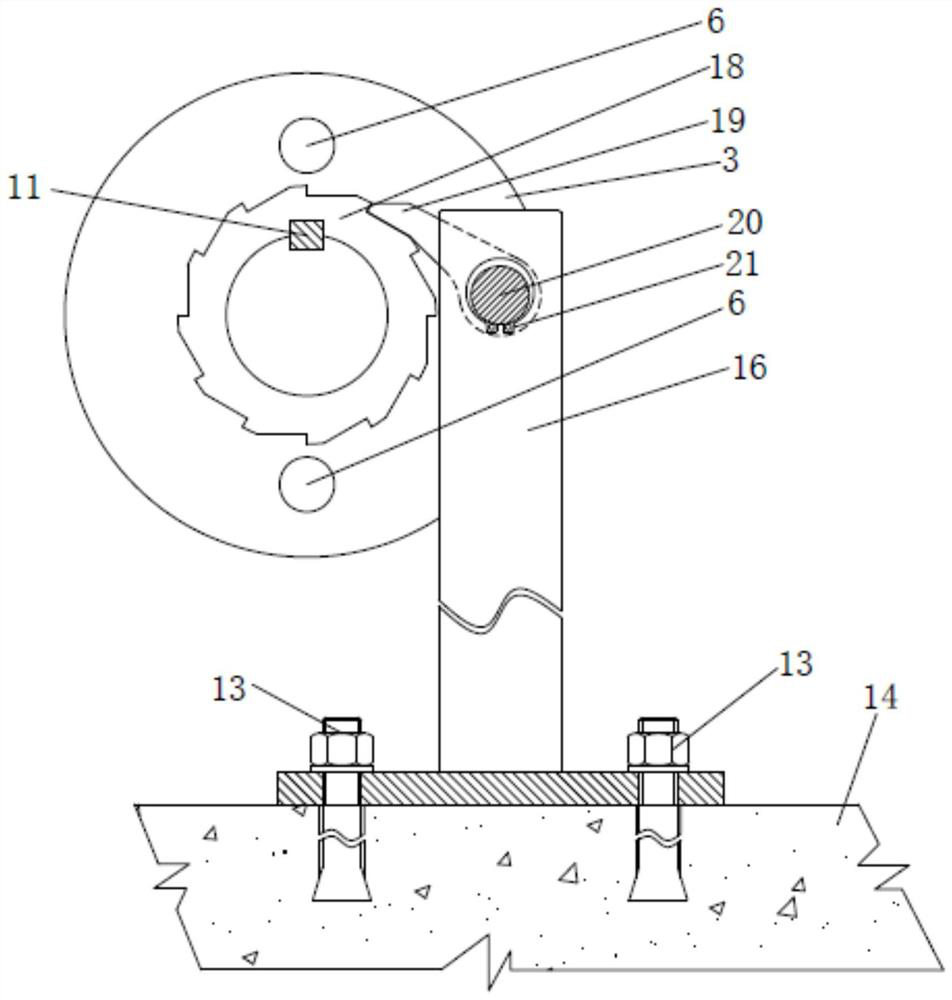

[0036] Such as Figure 2-4As shown, a manual turning device for a rotary filter screen provided by the present invention includes: a turning hand wheel 1, a first flange 3, a second flange 5, a pin 7, a nut 9, a key 11, an expansion bolt 13, a ground Foot steel plate 15, ratchet support 16, ratchet 18, ratchet 19, fixed pin 20 and jump ring 21.

[0037] Such as figure 2 As shown, the first flange 3 is fixedly connected to the center of the turni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com